Method for preparing antioxidant

A technology of hydroxybenzone and s-triazine, which is applied in the field of preparation of antioxidants, can solve problems such as pollution and endanger the health of workers, and achieve the effects of reducing pollution, rationalizing the production process and reducing harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Add 200 grams of isopropanol and 30 grams of distilled water into a 500ml four-necked bottle, add 24.9 grams of cyanuric acid and 18.5 grams of paraformaldehyde under stirring, and add 3.7 grams of catalyst triethylamine and 1.85 grams of dibutylamine after the dispersion is uniform. After stirring evenly, under the protection of nitrogen, when the temperature was raised to 65°C, 120 grams of 2.6-di-tert-butylphenol was added, and then the temperature was raised to reflux state. After reacting for 10 hours, the temperature was naturally lowered, cooled to 10°C, suction filtered, and dried to obtain The crude product was 148 grams, and 133 grams of the product were refined through recrystallization, with a yield of 88%. The mother liquor was recovered to obtain 3.2 grams of the product, with a yield of 2%, and the total yield was over 90%.

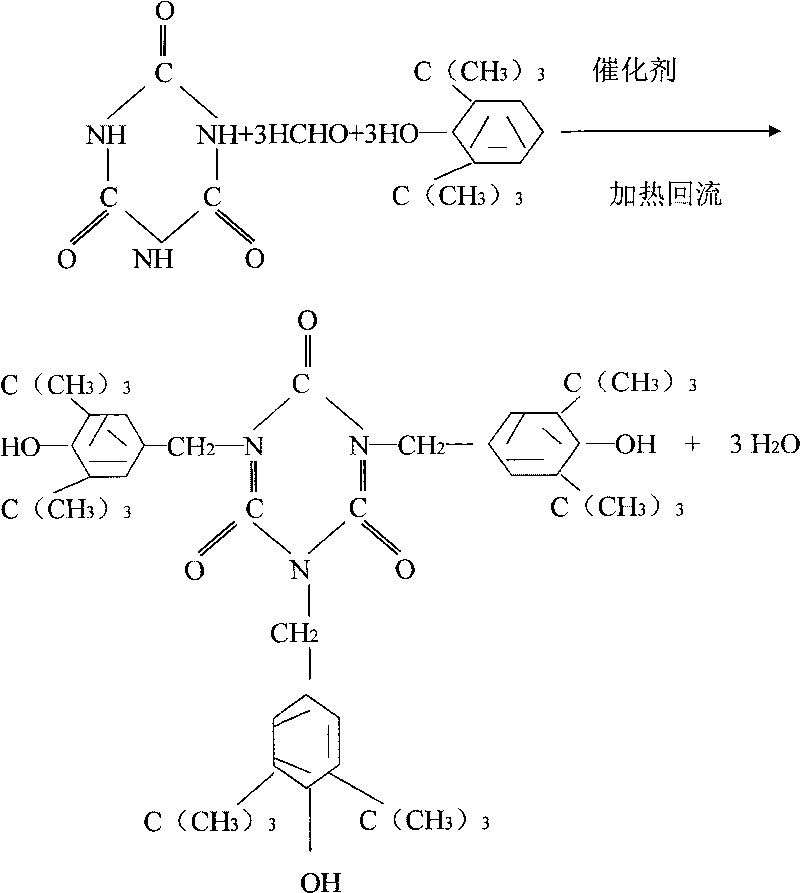

[0010] Reaction equation of the present invention is:

[0011]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com