Special protective material for polar rubber and preparation method thereof

A technology of protective materials and polar rubber, which is applied in the field of special protective materials for polar rubber and its preparation. It can solve the problems of easy migration, frosting and high price, and achieve the effects of low price, alleviating adhesion and improving process performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

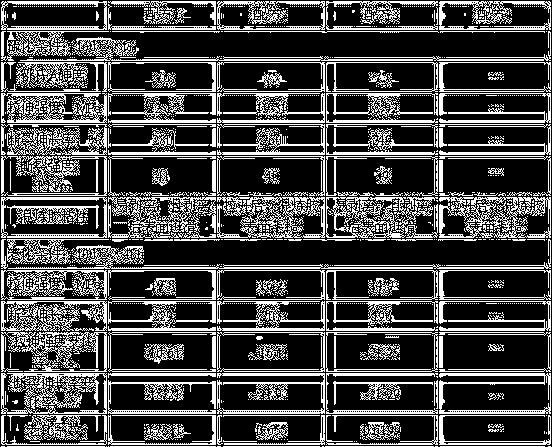

Image

Examples

Embodiment 1

[0021] A special protective material for polar rubber of the present invention consists of the following components (by weight): 40 parts of nickel dibutyldithiocarbamate, 30 parts of nickel terephthalate, and 30 parts of calcium terephthalate .

[0022] The method for preparing the special protective material for polar rubber comprises the following steps:

[0023] (1) Under constant stirring, mix alkali reduction waste water, dibutylamine, carbon disulfide and caustic soda in a certain proportion. After completely dissolving, add activated carbon with a mass percentage of 0.2% of the solution, and stir for 10 minutes to make it evenly dispersed in solution, and then filtered to obtain a decolorized, clear sodium salt solution;

[0024] (2) Under constant stirring, mix the sodium salt solution obtained in step (1) with the nickel chloride solution with a mass percentage of 35%, and continue to stir and react at a speed of 150 rpm for 60 minutes to obtain a mixed slurry A;

...

Embodiment 2

[0029] The difference between embodiment 2 and embodiment 1 is:

[0030] A special protective material for polar rubber of the present invention consists of the following components (by weight): 50 parts of nickel dibutyldithiocarbamate, 40 parts of nickel terephthalate, and 10 parts of calcium terephthalate .

[0031] The method for preparing the special protective material for polar rubber comprises the following steps:

[0032] (1) Under constant stirring, mix alkali reduction waste water, dibutylamine, carbon disulfide and caustic soda in a certain proportion. After completely dissolving, add activated carbon with a mass percentage of 0.2% of the solution, and stir for 20 minutes to make it evenly dispersed in solution, and then filtered to obtain a decolorized, clear sodium salt solution;

[0033] (2) Under continuous stirring, mix the sodium salt solution obtained in step (1) with the nickel chloride solution with a mass percentage of 60%, and continue to stir and reac...

Embodiment 3

[0037] The difference between embodiment 3 and embodiment 1 is:

[0038] A special protective material for polar rubber of the present invention consists of the following components (by weight): 45 parts of nickel dibutyldithiocarbamate, 35 parts of nickel terephthalate, and 20 parts of calcium terephthalate .

[0039] The method for preparing the special protective material for polar rubber comprises the following steps:

[0040] (1) Under constant stirring, mix the alkali reduction wastewater, dibutylamine, carbon disulfide and caustic soda in a certain proportion. After completely dissolving, add activated carbon with a mass percentage of 0.2% of the solution, and stir for 15 minutes to make it evenly dispersed in solution, and then filtered to obtain a decolorized, clear sodium salt solution;

[0041] (2) Under constant stirring, mix the sodium salt solution obtained in step (1) with the nickel chloride solution with a mass percentage of 45%, and continue to stir and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com