Binder with high adhesion performance for water-based ink

A technology of adhesion performance, water-based ink, applied in the direction of ink, application, household appliances, etc., can solve the problems of odor, volatile, color pattern damage, etc., to improve high temperature resistance, increase the degree of polymerization, and improve the effect of adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

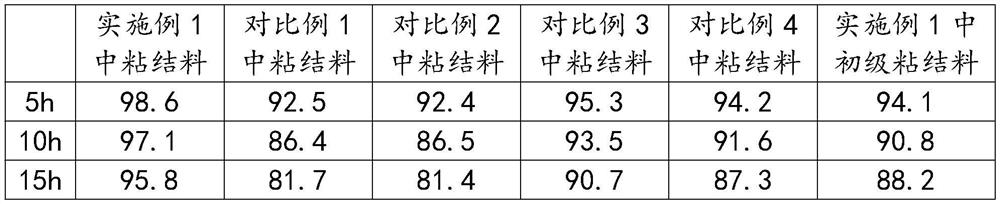

Examples

Embodiment 1

[0050] A kind of preparation process of the binder for water-based ink with high adhesion performance is as follows:

[0051] In the first step, add 1kg of the above-mentioned double-ended keto-dibasic acid monomer, 920g of the above-mentioned prepared double-ended keto-dibasic alcohol monomer and 2g dibutyltin dilaurate to the reactor in a nitrogen atmosphere, Raise the temperature to 160°C and stir slowly, heat the reaction for 1 hour, then raise the temperature by 20°C every 2 hours until the temperature of the system rises to 220°C, then keep the temperature unchanged for 3 hours until the acid value of the system drops below 10mgKOH / g, then cool down to 130°C and add Diethylene glycol ether acetate, adjust the solid content of the product to be 30%, add acetone to it after cooling to room temperature, wherein the acetone addition is half of diethylene glycol ether acetate, then continue to cool down to 5 ° C Add 530g of methyl bromide, seal the reaction tank, raise the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com