A method for fixing leather-wrapped borders

A fixing method and leather technology, applied in the surface pretreatment bonding method, adhesive heating bonding method, epoxy resin glue, etc., can solve the problems of easy arching and wrinkling of leather, and achieve Fast curing speed, improved tension and adhesion, and improved coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for fixing a leather-wrapped border, comprising the following steps:

[0042] (1) Pre-cutting treatment: Before the leather wraps the workpiece, the corners of the leather that are relatively easy to wrinkle are pre-cut and opened;

[0043] (2) Fixing with nails: After covering the workpiece with leather, stretch the leather-covered boundary to the back of the workpiece, and fix the non-corner parts that are not easy to wrinkle;

[0044] (3) Welding and fixing: The leather and the workpiece are hot-melted or ultrasonically welded at the corners of the leather-covered border that are relatively easy to wrinkle, and the edges are fixed and trimmed.

[0045] The invention pre-cuts and opens the corners of the leather that are relatively easy to wrinkle, and uses hot-melt or ultrasonic welding technology to weld and fix the leather and the workpiece at the corners of the leather-covered boundary that are relatively easy to wrinkle, so as to solve the problem of lea...

Embodiment 2

[0065] The difference between this embodiment and embodiment 1 is:

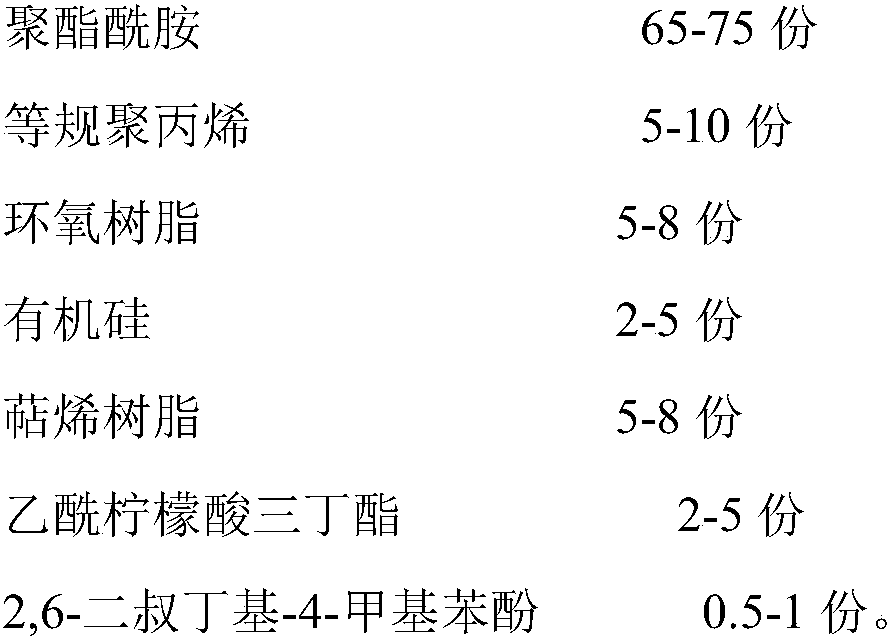

[0066] In the present embodiment, described hot melt adhesive comprises the component of following parts by weight:

[0067] Polyesteramide 69.5 parts

[0068] Isotactic polypropylene 10 parts

[0069] 8 parts epoxy resin

[0070] Silicone 2 parts

[0071] 8 parts terpene resin

[0072] Acetyl tributyl citrate 2 parts

[0073] 0.5 parts of 2,6-di-tert-butyl-4-methylphenol.

[0074] The preparation step of the polyester amide comprises: carrying out the esterification reaction of terephthalic acid, propylene glycol and triethylene glycol, and then adding isophthalic acid with a carbon number of C 12 The aliphatic dibasic acid, heptanediamine and caprolactam are subjected to esterification and amidation reactions, and polycondensation to obtain polyester amide.

[0075] The rest of the content of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0077] The difference between this embodiment and embodiment 1 is:

[0078] In the present embodiment, described hot melt adhesive comprises the component of following parts by weight:

[0079] Polyesteramide 75 parts

[0080] Isotactic polypropylene 5 parts

[0081] 5 parts epoxy resin

[0082] Silicone 2 parts

[0083] 7 parts terpene resin

[0084] Acetyl tributyl citrate 5 parts

[0085] 1 part of 2,6-di-tert-butyl-4-methylphenol.

[0086] The preparation step of the polyester amide comprises: carrying out the esterification reaction of terephthalic acid, hexanediol and triethylene glycol, and then adding isophthalic acid with a carbon number of C 8 The fatty dibasic acid, pentamethylenediamine and caprolactam are subjected to esterification and amidation reactions, and polycondensation to obtain polyester amide.

[0087] The rest of the content of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com