Automatic necking and sizing device for tube end

An automatic shrinking technology, which is applied in the field of steel pipe shrinking and sizing equipment, can solve the problems of inability to move axially, clamp marks on the clamped part of the pipe, and axial series movement, etc., to meet the requirements of precise positioning and processing, and avoid assembly If the gap is too large, the effect of avoiding axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

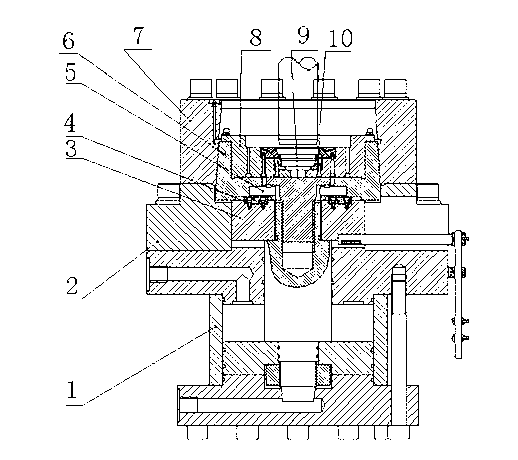

[0019] refer to figure 1 , the pipe end automatic shrinking and sizing device of the present embodiment, which includes a hydraulic cylinder 1, a mounting flange 2, a movable push plate 3, a slider 6, a slider inner sleeve 8, a sliding sleeve 7, a module 9 and a clamp block 10 , the mounting flange 2 is installed on the hydraulic cylinder 1, the hydraulic cylinder 1 is provided with a piston, the movable push plate 3 is connected with the piston rod of the piston, and the slider 6 is installed above the movable push plate 3. The slider 6 is set in the sliding sleeve 7 , the slider inner sleeve 8 is installed in the slider 6 , and the clamp block 10 is installed in the slider inner sleeve 8 . The inner cavity of the sliding sleeve 7 is in the shape of a truncated cone, and the outer surface of the slider 6 in contact with the sliding sleeve 7 is in the shape of a truncated cone. The module 9 is installed in the middle of the slider 6 and below the inner sleeve 8 of the slider....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com