Device and method for assembling piston pin hole bushing

A piston pin hole and bushing technology, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of bushing assembly stuck and scrapped, large assembly position error, reduced assembly clearance, etc., and achieve large assembly clearance , High accuracy of assembly position, small effect of heat absorption expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

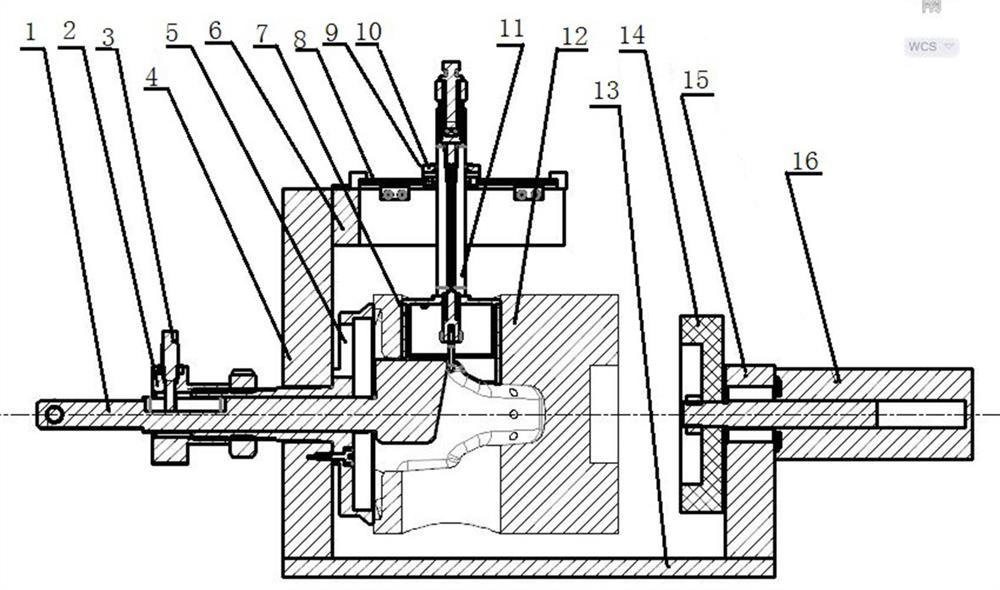

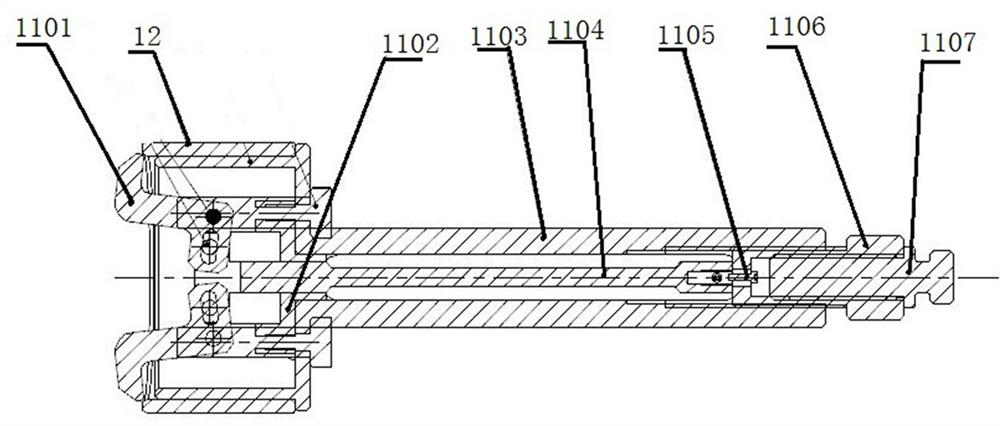

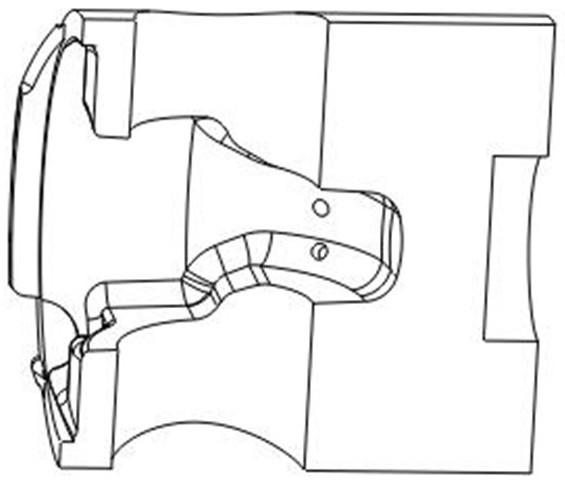

[0035] Such as Figure 1-Figure 4 As shown, a piston pin hole bushing assembly device is used for assembling the bushing 7 on the pin hole on the engine piston 12. One end of the piston 12 is provided with a countersunk cavity, and the countersunk cavity is arranged along the side of the piston 12. The axial direction is symmetrical, and the pin hole runs through the countersunk cavity along the direction perpendicular to the axial direction of the piston 12, including the mounting seat, the fixing device, the clamping device of the bushing 7 and the angle positioning device; wherein:

[0036] The mounting seat includes a base 13 and a support body a4 and a support body b15 respectively fixed at both ends of the base 13, and the fixing device includes a clamping cylinder 16 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com