Electric spray engine speed change working condition calibration and execution system

An execution system and engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as the inability to guarantee the accuracy of calibration results, and achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the drawings and examples.

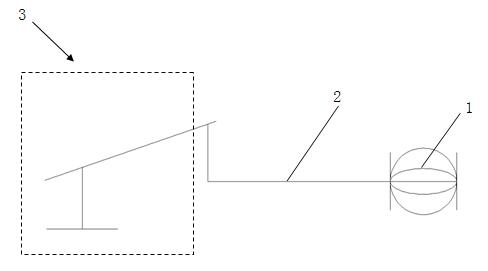

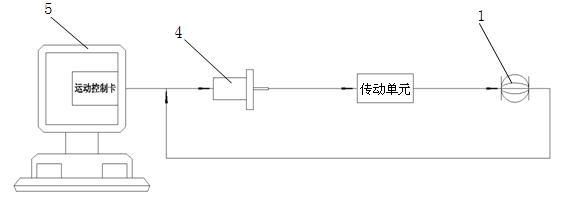

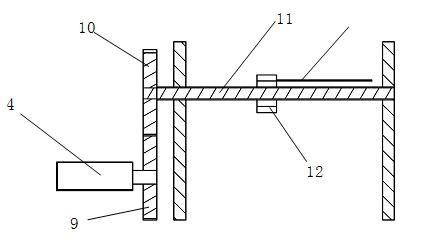

[0025] figure 2 It is a structural schematic diagram of the variable speed working condition calibration execution system of the EFI engine of the present invention; image 3 It is a schematic diagram of the lead screw transmission unit in the calibration execution system of the variable speed working condition of the electronic fuel injection engine of the present invention; Figure 4 It is a schematic diagram of the wheel shaft transmission unit in the calibration execution system of the variable speed working condition of the EFI engine of the present invention.

[0026] Case time analysis, remove if Figure 2 to Figure 4 As shown, the variable-speed working condition calibration execution system of the EFI engine of the present invention includes: a throttle body 1, which changes the working state of the engine by changing the throttle opening; a computer 5, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com