Capacitor leg cutting machine with pin detection

A technology with pins and pin-cutting machines, which is applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of time-consuming, labor-intensive, and low work efficiency, and achieve the effect of saving labor and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention is described in further detail, but structure of the present invention is not limited to following embodiment:

[0023] 【Example】

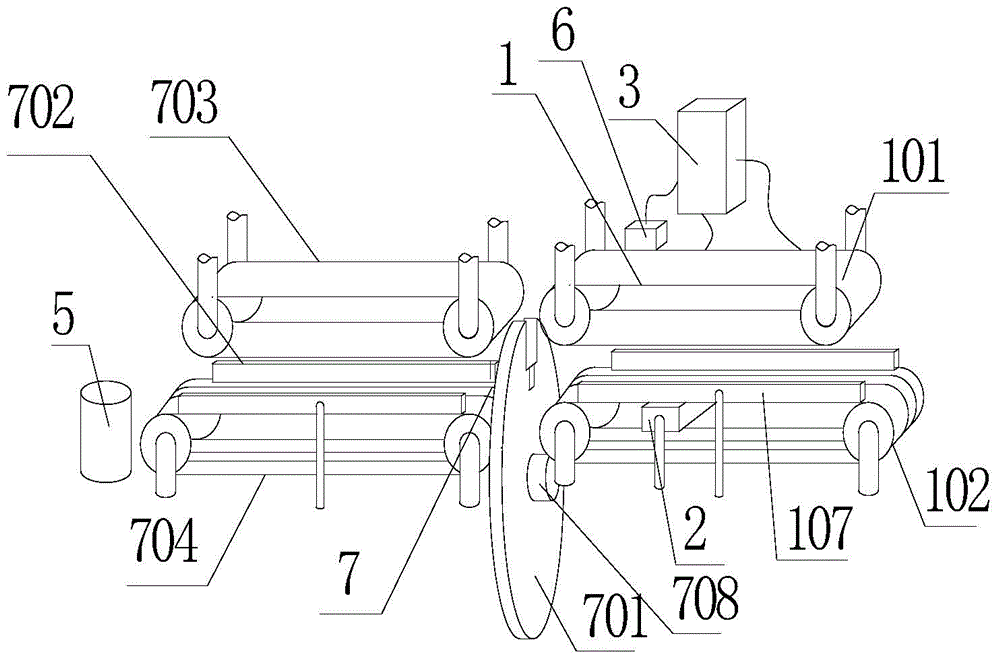

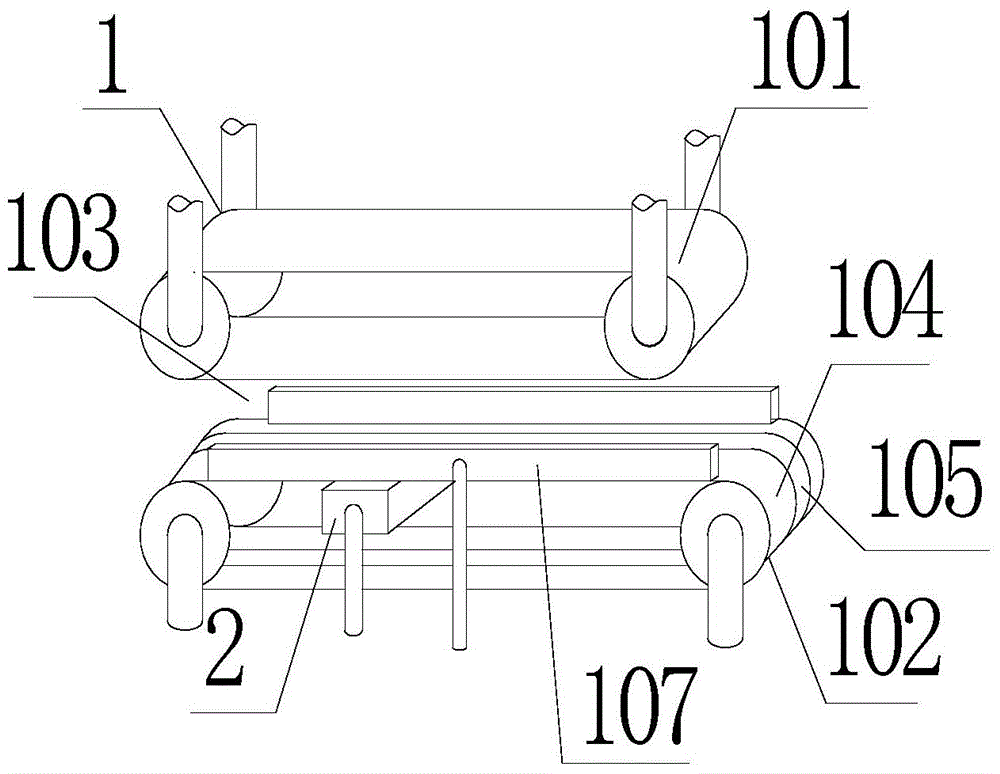

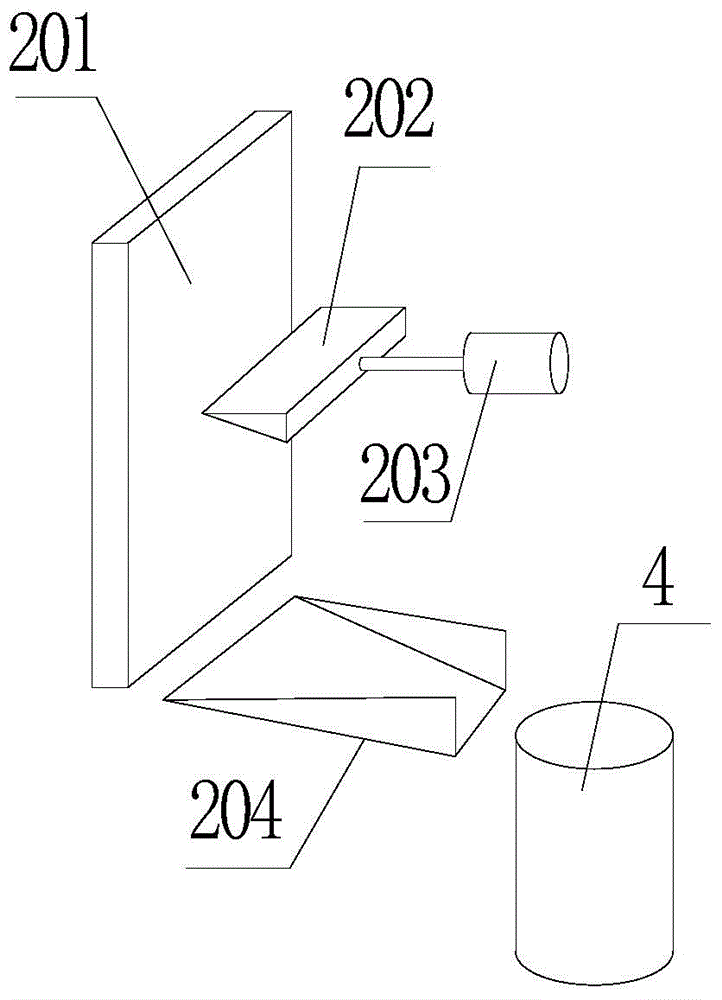

[0024] like Figure 1-6 As shown, the capacitive foot cutting machine with pin detection includes the first clamping and traveling device 1, the cutting device 2, the PLC controller 3 and the screening device 7, and the first clamping and traveling device 1 includes an upper walking belt 101 and the lower walking belt 102 positioned directly below the upper walking belt 101, the upper walking belt 101 and the lower walking belt 102 are conveyor belts, between the lower belt surface of the upper walking belt 101 and the upper belt surface of the lower walking belt 102 A clamping space 103 is formed, and the driving wheel of the lower walking belt 102 is covered with two parallel and spaced belts 104, and a through groove 105 is formed between the two belts 104, and the foot cutter 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com