Two-component structural adhesive and preparation method thereof

A structural adhesive, two-component technology, applied in the direction of adhesives, epoxy resin adhesives, non-polymer adhesive additives, etc., can solve the problems of hard disk drives not operating normally, structural adhesive ratio imbalance, and affecting bonding performance. Achieve the effects of long pot life, low curing temperature, and prevention of proportional imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

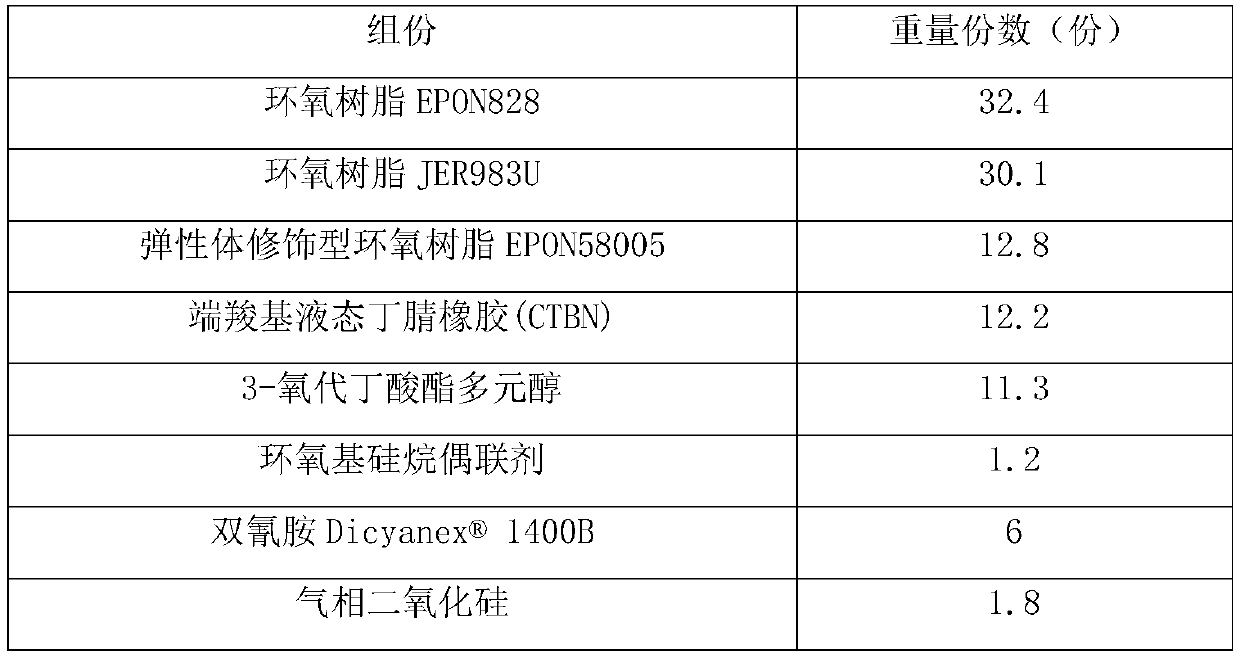

Embodiment 1

[0052] A kind of two-component structural glue, its raw material components include by mass percentage:

[0053] Component A, the mass percentage of component A is based on 100%, including:

[0054] 40% epoxy resin, 30% toughening agent, 25% diluent, 1% crosslinking agent, 4% reinforcing filler;

[0055]Component B, the mass percentage of component B is based on 100%, including:

[0056] Aliphatic amine polyamine 20%, epoxy resin-aliphatic amine copolymer 40%, toughening agent 20%, triamine accelerator 10%, reinforcing filler 10%;

[0057] The mass ratio of component A to component B is 1:1. Among them, the epoxy resin adopts the epoxy resin whose epoxy equivalent is 200-210g / eq, and the viscosity at 25°C is 1600-2000cps, and the epoxy resin whose epoxy equivalent is 325-375g / eq, and the viscosity at 25°C is 3000-8000cps A mixture of elastomer-modified epoxy resins, aliphatic amine polyamines with an active hydrogen equivalent of 42.6g / eq, isophorone diamine with a viscosit...

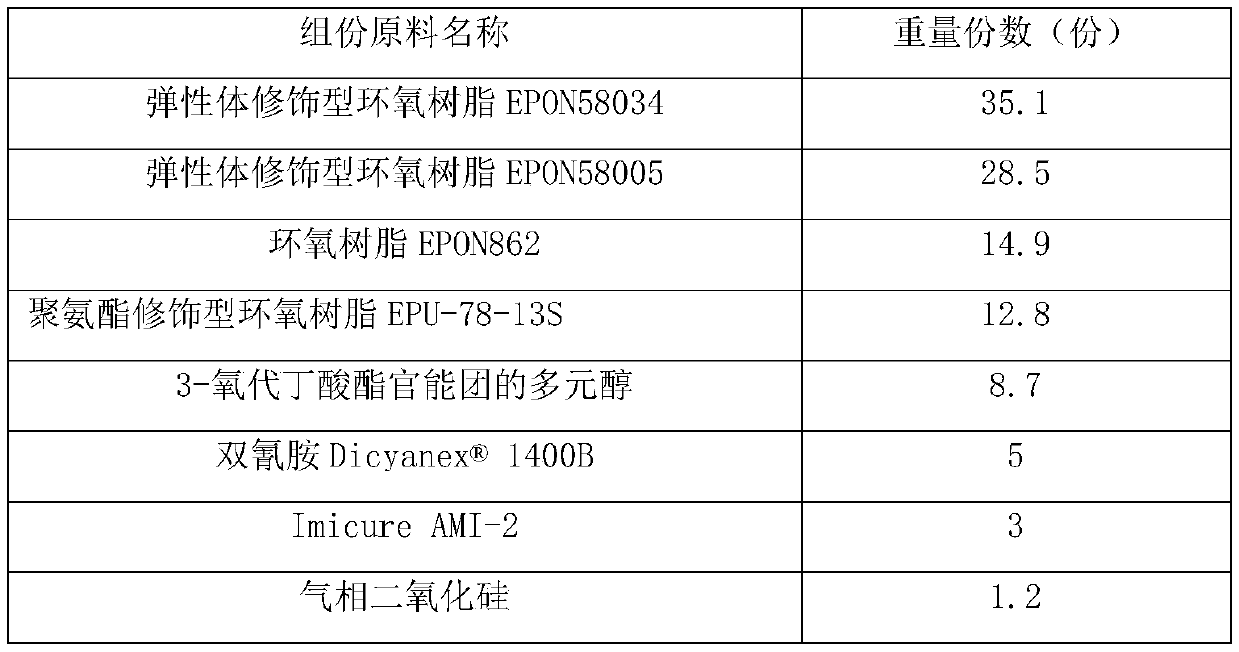

Embodiment 2

[0064] A kind of two-component structural glue, its raw material components include by weight parts:

[0065] A kind of two-component structural glue, its raw material components include by mass percentage:

[0066] Component A, the mass percentage of component A is based on 100%, including:

[0067] 50% epoxy resin, 25% toughening agent, 20% diluent, 2% crosslinking agent, 3% reinforcing filler;

[0068] Component B, the mass percentage of component B is based on 100%, including:

[0069] Aliphatic amine polyamine 50%, epoxy resin-aliphatic amine copolymer 20%, toughening agent 20%, triamine accelerator 5%, reinforcing filler 5%; the mass ratio of component A to component B It is 4:1. Among them, the epoxy resin adopts epoxy resin with epoxy equivalent of 182-192g / eq, viscosity at 25°C of 11000-15000cps, epoxy equivalent of 220-240g / eq, viscosity at 25°C of 2000-4000cps The mixture of polyurethane modified epoxy resin and epoxy equivalent of 275-305g / eq, viscosity of 4000...

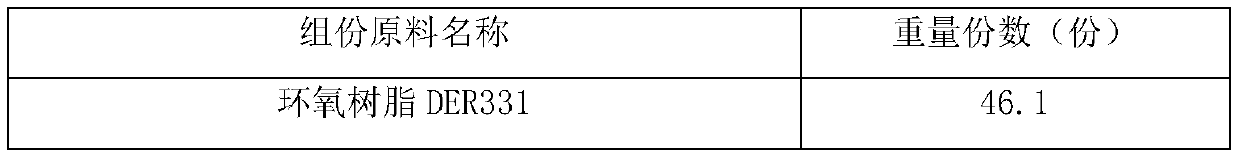

Embodiment 3

[0077] A kind of two-component structural glue, its raw material components include by mass percentage:

[0078] Component A, the mass percentage of component A is based on 100%, including:

[0079] 90% epoxy resin, 5% toughening agent, 3% diluent, 1% crosslinking agent, 1% reinforcing filler;

[0080] Component B, the mass percentage of component B is based on 100%, including:

[0081] Aliphatic amine polyamine 60%, epoxy resin-aliphatic amine copolymer 10%, toughening agent 10%, triamine accelerator 10%, reinforcing filler 10%; the mass ratio of component A to component B It is 10:1.

[0082] Among them, the epoxy resin adopts the epoxy equivalent of 232-254g / eq, the viscosity at 25°C is 6000-8000cps core-shell rubber modified epoxy resin and the epoxy equivalent is 285-310g / eq, and the viscosity at 50°C is 16000-20000cps core-shell rubber-modified epoxy resin mixture, the aliphatic amine polyamine adopts polyetheramine with an active hydrogen equivalent of 60g / eq, a visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com