Anti-aging modified calcium carbonate for paint-latex paint and preparation method thereof

A latex paint and anti-aging technology, which is applied in latex paint, chemical instruments and methods, dyed organosilicon compound treatment, etc., can solve the problems of composite material performance degradation, weak matrix bonding force, and two-phase interface defects, etc., to achieve improved anti-aging Effects of aging, improvement of surface gloss, uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

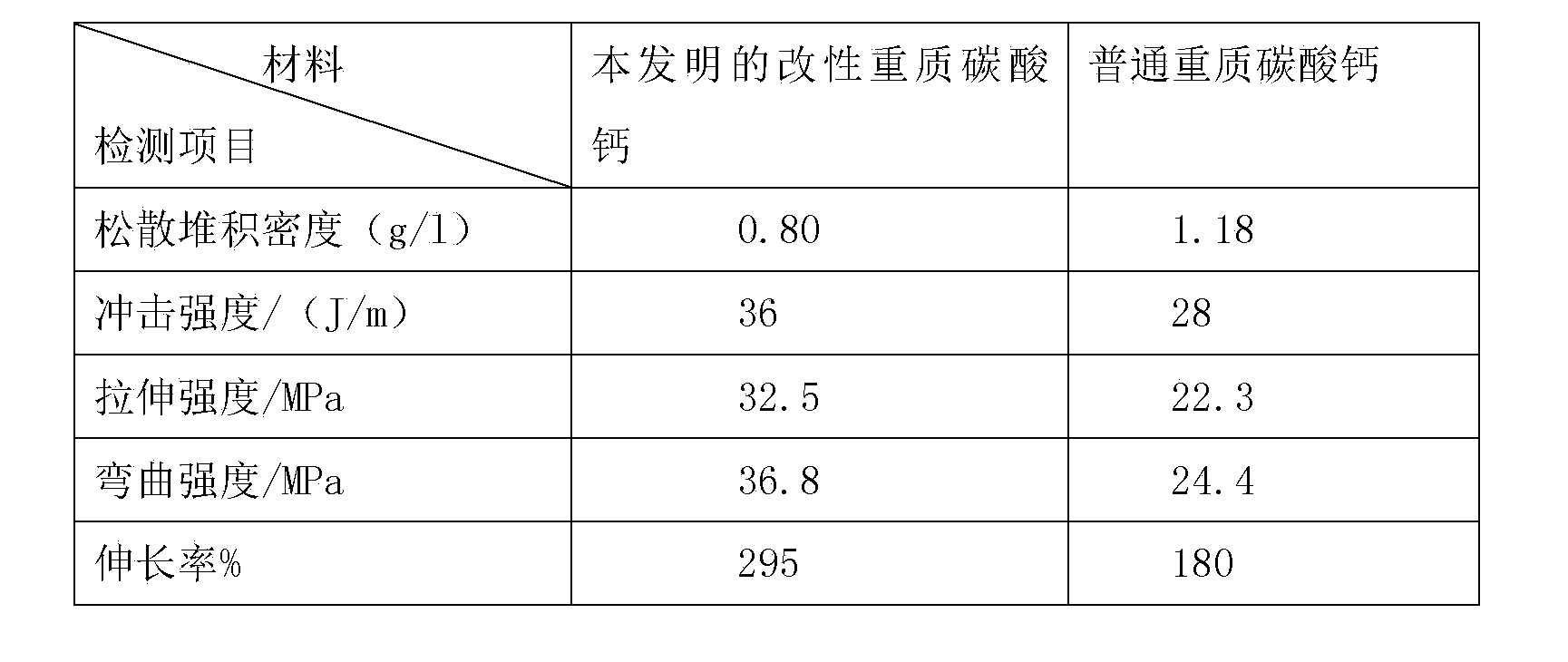

Image

Examples

Embodiment Construction

[0010] A kind of anti-aging paint-modified ground calcium carbonate for latex paint,

[0011] First, weigh 800 mesh heavy calcium carbonate 100, oleic acid polyoxyethylene ester 2, polyethylene wax 0.6, styrene 1, aluminum nitride powder 0.4, triphenyl phosphite 2, aziridine cross by weight (kg). Coupling agent XR-100 0.3, polyvinyl alcohol 0.2, silane coupling agent KH550 2, styrene-acrylic emulsion 0.4, emulsifier OP-10 2, alumina 0.5, nano-silica (VK-SP30) 1, epoxy soybean oil 2. Ammonium polyphosphate 0.5, zinc powder 0.9,

[0012] First, dry the heavy calcium carbonate at 90-95°C until the water content is less than 0.5%, and then add it to a high-speed mixer. After mixing polyoxyethylene oleate, polyethylene wax, styrene, aluminum nitride powder, Triphenyl phosphite, aziridine crosslinking agent XR-100, polyvinyl alcohol, silane coupling agent KH550, mix according to the formula ratio, then add to calcium carbonate, heat up to 95-100°C and stir at high speed for 4-5 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com