PET compound of heat and ageing resistant insulation film, and preparation method thereof

A heat-resistant aging and insulating film technology, applied in the field of polyester film manufacturing, can solve the problems of affecting the long-term heat-resistant oxygen performance of the film, not easy to uniformly disperse, and the effect is not obvious enough, so as to delay the performance deterioration process, improve the water vapor barrier performance, Enhance the effect of interface interactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

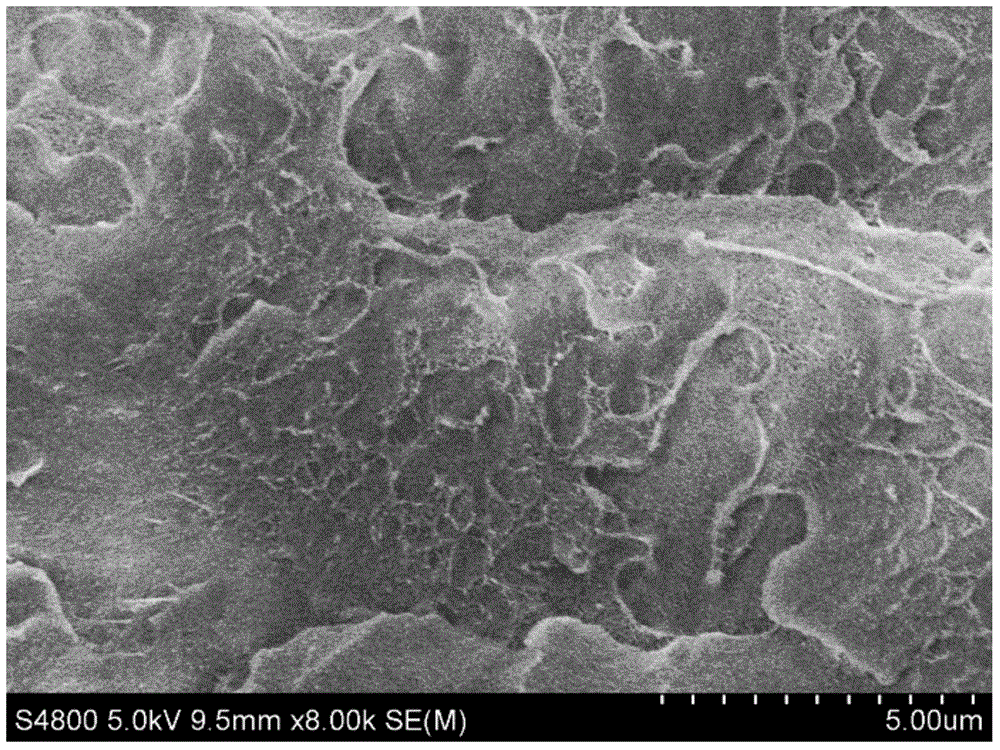

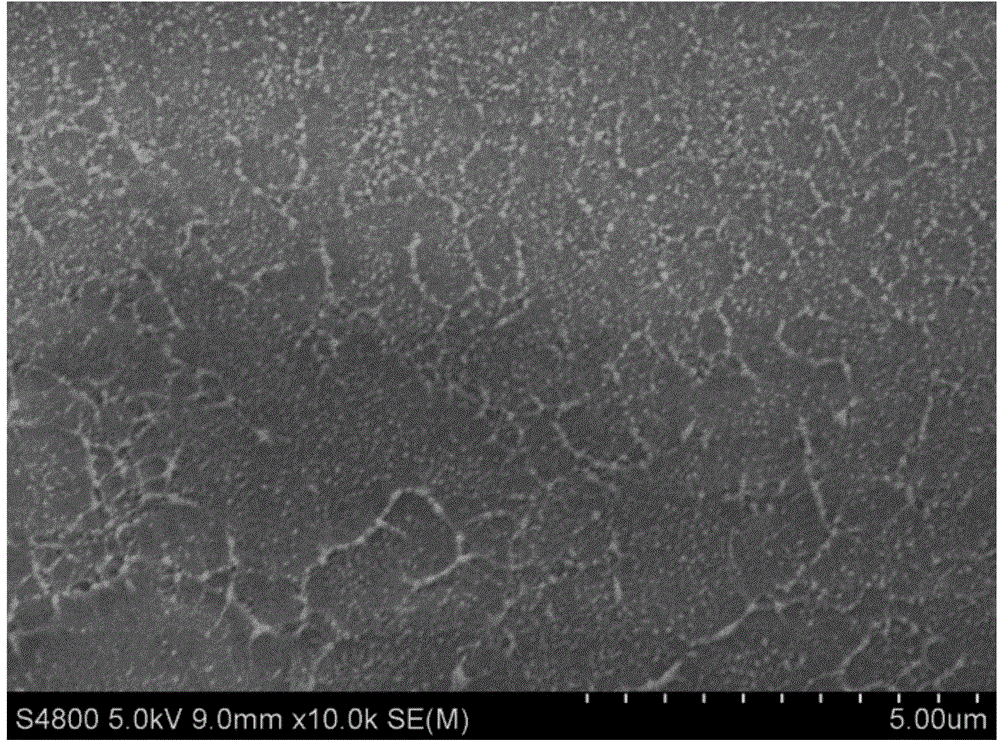

[0022] The PET compound of heat-resistant aging insulating film of the present invention, raw material composition comprises 100 parts of PET resin chips, 0.1~1.0 parts of nano particle nucleating agent, 10~15 parts of ultrafine nylon powder, 0.1~ 1.0 parts of ammonium polyphosphate, 1 to 10 parts of pentaerythritol and 1 to 6 parts of triphenyl phosphite, the nanoparticle nucleating agent of the present invention is nano inorganic particles treated with silane coupling agent, and the nano inorganic particles are processed by silane coupling The joint agent is processed into a nano-particle nucleating agent to improve the fraction of the nano-inorganic particles in the PET matrix. At the same time, mixing with ammonium polyphosphate, pentaerythritol, and triphenyl phosphite can further disperse the nano-inorganic particles, and has the ability to PET insulating film has better flame retardant effect. The ultrafine nylon powder of the present invention is nylon powder of 600~20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com