Preparation method of itaconic acid grafted ethylene-octylene block copolymer granules

An octene block and copolymer technology, which is applied in the field of preparation of itaconic acid grafted ethylene-octene block copolymer pellets, can solve the problems of poor compatibility of direct blending and decreased mechanical strength of alloy materials, etc. Achieve the effect of improving notched impact strength, elongation at break and impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

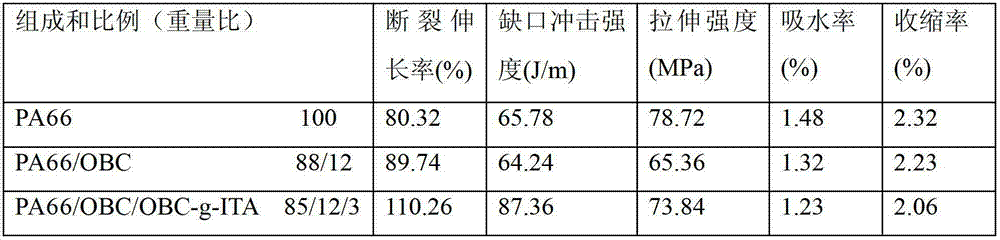

Embodiment 1

[0016] Set the density to 0.877g / cm 3 93.0kg of OBC with a melting point of 122°C, a tensile strength of 9.5MPa, and an elongation at break of 1600%, 3.0kg of ITA with a mass percentage of 99.8%, and a melting point of 166°C, BPO0.15kg, triphenyl phosphite Put 0.35 kg of ester in a mixer, control the mixer speed to 250r / min, temperature 75°C, stir and mix for 7 minutes to form a mixture; put the mixture in a reactive twin-screw extruder for melting and grafting reaction, and control the reactive twin-screw extruder The temperature of the discharge cylinder is 155°C in zone I, 160°C in zone II, 165°C in zone III, 170°C in zone IV, 175°C in zone V, 175°C in zone VI, 175°C in zone VII, and 170°C in zone VIII. The die head temperature is 167°C; Control the screw speed of the reactive twin-screw extruder to 70r / min, extrude and pelletize itaconic acid grafted ethylene-octene block copolymer (OBC-g-ITA) pellets.

[0017] The OBC-g-ITA granule material that embodiment 1 makes, itaco...

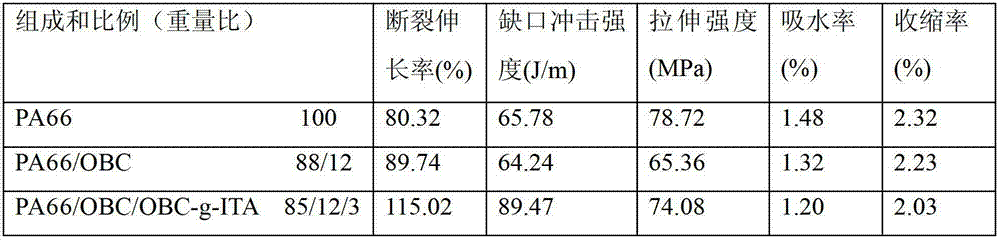

Embodiment 2

[0021] Set the density to 0.877g / cm 3 96.5kg of OBC with a melting point of 122°C, a tensile strength of 9.5MPa, and an elongation at break of 1600%, 6.0kg of ITA with a mass percentage of 99.8%, and a melting point of 166°C, BPO0.35kg, triphenyl phosphite Put 0.65kg of ester in a mixer, control the speed of the mixer to 250r / min, temperature 76°C, stir and mix for 7 minutes to form a mixture; put the mixture in a reactive twin-screw extruder for melting and grafting reaction, and control the reactive twin-screw extruder The temperature of the discharge cylinder is 158°C in zone I, 163°C in zone II, 168°C in zone III, 173°C in zone IV, 178°C in zone V, 178°C in zone VI, 178°C in zone VII, and 173°C in zone VIII. The die head temperature is 170°C; Control the screw speed of the reactive twin-screw extruder to 90r / min, extrude and pelletize itaconic acid grafted ethylene-octene block copolymer (OBC-g-ITA) pellets.

[0022] The OBC-g-ITA granular material that embodiment 2 makes...

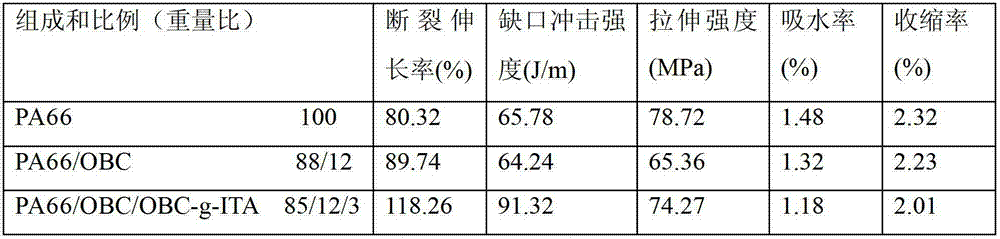

Embodiment 3

[0026] Set the density to 0.877g / cm 3 94.5kg of OBC with a melting point of 122°C, a tensile strength of 9.5MPa, and an elongation at break of 1600%, 4.5kg of ITA with a mass percentage of 99.8%, and a melting point of 166°C, BPO0.28kg, triphenyl phosphite Put 0.5kg of ester in a mixer, control the speed of the mixer to 250r / min, temperature 74°C, stir and mix for 7 minutes to form a mixture; put the mixture in a reactive twin-screw extruder for melting and grafting reaction, and control the reactive twin-screw extruder The temperature of the discharge cylinder is 157°C in zone I, 162°C in zone II, 166°C in zone III, 172°C in zone IV, 177°C in zone V, 177°C in zone VI, 177°C in zone VII, and 172°C in zone VIII. The die head temperature is 168°C; Control the screw speed of the reactive twin-screw extruder to 80r / min, extrude and pelletize itaconic acid grafted ethylene-octene block copolymer (OBC-g-ITA) pellets.

[0027] Table 3 PA66, PA66 / OBC and PA66 / OBC / OBC-g-ITA physical a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com