Preparation method of polypropylene beta crystalline nucleating agent

A technology of β crystal form and nucleating agent, which is applied in the field of preparation of polypropylene β crystal form nucleating agent, and can solve problems such as inability to carry out large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

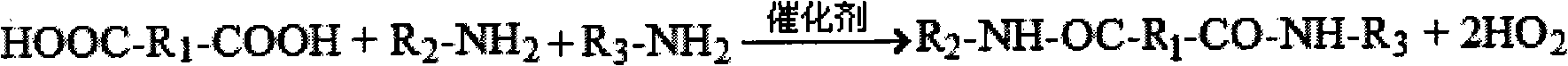

[0011] The preparation method of the polypropylene beta crystal form nucleating agent provided by the invention comprises that in the presence of a catalyst and a solvent, a dibasic carboxylic acid is contacted with an amine to carry out condensation reaction. In the present invention, the selection of the catalyst and the solvent takes into account the solubility of the solvent to the catalyst and the reaction raw materials such as dicarboxylic acid and amine and the reactivity of the reaction system of the dicarboxylic acid and amine, Therefore, in the method provided by the invention, the catalyst is selected from one or more of phosphorus pentoxide, polyphosphoric acid and triphenyl phosphite, and the polyphosphoric acid can be diphosphoric acid, tripolyphosphoric acid and tetrapolyphosphoric acid. At least one of phosphoric acid (also known as polyphosphoric acid), and pyridine is selected as the solvent, so as to ensure that the reaction system of the dicarboxylic acid an...

Embodiment 1

[0022] This example is used to illustrate the preparation method of the polypropylene β crystal form nucleating agent provided by the present invention.

[0023] Preparation of N, N'-dicyclopentyl terephthalamide

[0024] Add 0.022 mol of terephthalic acid and 100 ml of pyridine (1.24 mol) into a four-port reaction kettle equipped with a stirrer, an addition funnel, a thermometer and a condenser, and stir to dissolve. Then, add 0.054 moles of cyclopentylamine and 0.054 moles of triphenyl phosphite under stirring, and react at 100°C for 1.5 hours under normal pressure, then add a solution with a volume ratio of isopropanol / water of 1:1 300 ml, stirred for 30 minutes, then filtered, and the filtered precipitate was washed with tap water, and dried to obtain 6.3 g of white powder as nucleating agent A1. It was identified that the white powder was 0.021 mol of N,N'-dicyclopentyl terephthalamide, therefore, the yield was 95.45%.

Embodiment 2

[0029] This example is used to illustrate the preparation method of the polypropylene β crystal form nucleating agent provided by the present invention.

[0030] Preparation of N, N'-dihexyl-2,6-naphthalene dicarboxamide

[0031] Add 0.026 mol of 2,6-naphthalene dicarboxylic acid and 100 ml of pyridine (1.24 mol) into a four-port reaction kettle equipped with a stirrer, an addition funnel, a thermometer and a condenser, and stir to dissolve. Then, add 0.052 mole of hexylamine and 0.062 mole of polyphosphoric acid under stirring, react at 120°C for 1 hour under normal pressure, add isopropanol / water volume ratio and be 300 milliliters of the solution of 1:1, Stir for 30 minutes, then filter, wash the filtered precipitate with tap water, and dry to obtain 9.15 g of white powder as nucleating agent A2. It was identified that the white powder was 0.024 mol of N,N'-dihexyl-2,6-naphthalene dicarboxamide, therefore, the yield was 92.31%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com