Heat-conducting electronic packaging composite and preparation method thereof

A composite material and electronic packaging technology, applied in the field of materials, can solve the problems of high density, insufficient thermal conductivity, and high cost, and achieve good thermal conductivity, excellent thermal stability, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

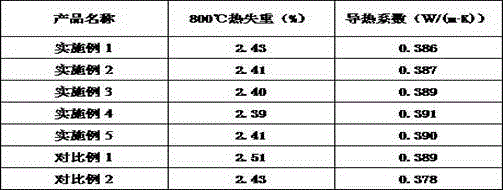

Examples

Embodiment 1

[0025] A heat-conducting electronic packaging composite material, prepared from the following components in parts by weight: 30 parts of bisphenol A epoxy resin, 10 parts of nano-alumina, 5 parts of nano-silicon dioxide, 1 part of neodymium acetylacetonate, 3,5- 1 part of diaminobenzoic acid, 1 part of silane coupling agent KH-5511, 1 part of γ-aminopropyltriethoxysilane, 1 part of lithium chloride, 0.2 part of N-methylpyrrolidone, 0.5 part of pyridine, triphosphite 0.1 part of phenyl ester, 0.5 part of N-aminoethylpiperazine, 40 parts of N,N-dimethylformamide, 1 part of trimethylhexamethylenediamine, 50-70 parts of acetone, 80 parts of methanol, water 80 servings.

[0026] The preparation method of the above-mentioned heat-conducting electronic packaging composite material is as follows: first mix nano-alumina, nano-silicon dioxide, silane coupling agent KH-551, γ-aminopropyltriethoxysilane and water, and use a magnetic stirrer at a temperature of 70 ℃, stirred for 3 hours a...

Embodiment 2

[0028] A heat-conducting electronic packaging composite material, prepared from the following components in parts by weight: 35 parts of bisphenol A epoxy resin, 12 parts of nano-alumina, 6 parts of nano-silicon dioxide, 1.5 parts of neodymium acetylacetonate, 3,5- 1.2 parts of diaminobenzoic acid, 1.3 parts of silane coupling agent KH-5511, 1.5 parts of γ-aminopropyl triethoxysilane, 1.2 parts of lithium chloride, 0.3 parts of N-methylpyrrolidone, 0.6 parts of pyridine, triphosphite 0.15 parts of phenyl ester, 0.6 parts of N-aminoethylpiperazine, 45 parts of N,N-dimethylformamide, 1.5 parts of trimethylhexamethylenediamine, 55 parts of acetone, 85 parts of methanol, and 85 parts of water .

[0029] The preparation method of the above-mentioned heat-conducting electronic packaging composite material is as follows: first mix nano-alumina, nano-silicon dioxide, silane coupling agent KH-551, γ-aminopropyltriethoxysilane and water, and use a magnetic stirrer at a temperature of 80...

Embodiment 3

[0031] A heat-conducting electronic packaging composite material, prepared from the following components in parts by weight: 40 parts of bisphenol A epoxy resin, 15 parts of nano-alumina, 7.5 parts of nano-silicon dioxide, 2 parts of neodymium acetylacetonate, 3,5- 1.5 parts of diaminobenzoic acid, 1.5 parts of silane coupling agent KH-5511, 2 parts of γ-aminopropyltriethoxysilane, 1.5 parts of lithium chloride, 0.35 parts of N-methylpyrrolidone, 0.75 parts of pyridine, triphosphite 0.2 parts of phenyl ester, 0.75 parts of N-aminoethylpiperazine, 50 parts of N,N-dimethylformamide, 2 parts of trimethylhexamethylenediamine, 60 parts of acetone, 90 parts of methanol, 90 parts of water .

[0032] The preparation method of the above-mentioned heat-conducting electronic packaging composite material is as follows: first mix nano-alumina, nano-silicon dioxide, silane coupling agent KH-551, γ-aminopropyltriethoxysilane and water, and use a magnetic stirrer at a temperature of 85 ℃, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com