A kind of reflective solar spectrum modified polyolefin elastomer functional film material and preparation method

A polyolefin elastomer and film material technology, applied in the field of functional polymer materials and preparation, can solve problems such as application limitations, high energy consumption of cooling equipment, and threats to sustainable development, and achieve low prices, easy access to raw materials, and high-quality technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

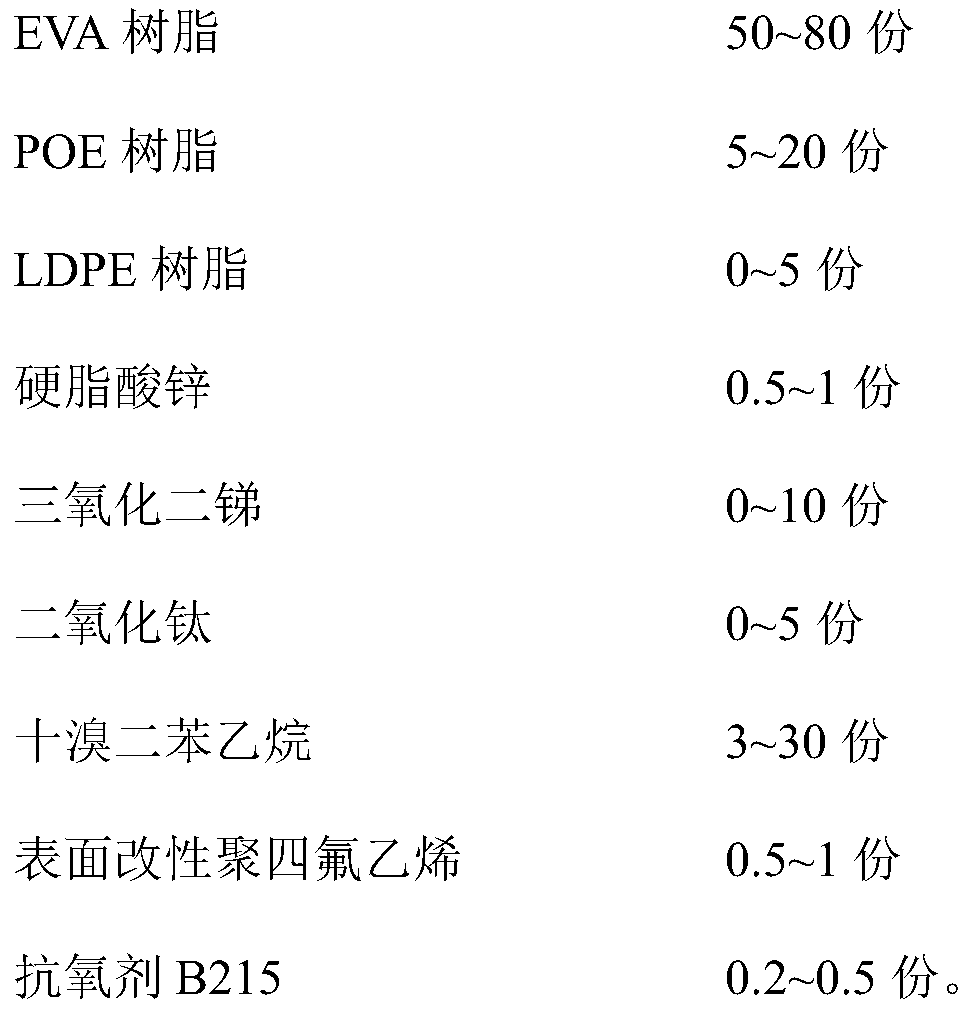

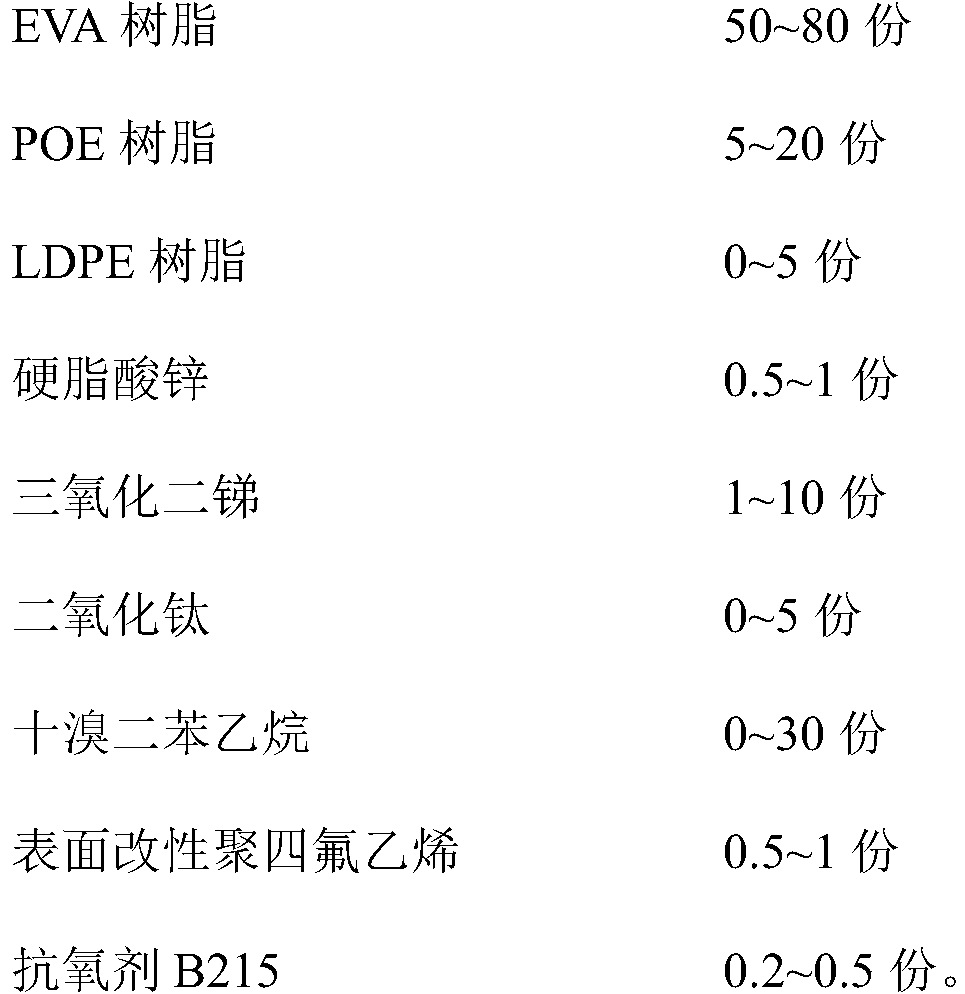

[0042] Raw material formula (mass ratio, part): EVA resin (190 ℃ * 2.16kg melt mass flow rate = 2.0g / 10min, VAc content = 15wt%) 80, POE resin (190 ℃ * 2.16kg melt mass flow rate = 0.5g / 10min, octene content = 20wt%) 13, surface-modified high-purity antimony trioxide (99.8% raw material purity before modification) 7 (the most probable distribution of particle size is 0.5 μm and 1.0 μm two kinds of particles 3 and 4), zinc stearate 1.0, PS resin content 30wt% surface coating modified ultra-high molecular weight polytetrafluoroethylene 0.5, antioxidant B215 0.2.

[0043] Preparation process: ①Surface modification of antimony trioxide: Add 1g of coupling agent KH845-4 into 100mL of absolute ethanol solvent at 25°C, stir for 15min to disperse coupling agent KH845-4 in the solvent to obtain a uniform solution; add 99g of antimony trioxide to the solution and continue to stir for 45 minutes, so that the coupling agent KH845-4 and antimony trioxide are in full contact and dispersed e...

Embodiment 2

[0049]Raw material formula (mass ratio, part): EVA resin (190 ℃ * 2.16kg melt mass flow rate = 3.0g / 10min, VAc content = 30wt%) 65, POE resin (190 ℃ * 2.16kg melt mass flow rate = 0.5g / 10min, octene content = 10wt%) 20, LDPE resin (190 ℃ × 2.16kg melt mass flow rate = 2.0g / 10min) 5, surface modified high-purity antimony trioxide (raw material before modification Purity 99.8%) 10 (the most probable distribution of particle size 0.5 μm and 1.0 μm two kinds of particles are 6 and 4), zinc stearate 0.5, the surface coating modification of PS resin content 30wt% ultra-high molecular weight polytetrafluoroethylene Ethylene 1.0, antioxidant B215 0.5.

[0050] Preparation process: ①Surface modification of antimony trioxide: add 1g of coupling agent KH845-4 into 100mL of absolute ethanol solvent at 25°C, stir for 10min to disperse coupling agent KH845-4 in the solvent to obtain a uniform solution; add 99g of antimony trioxide to the solution and continue to stir for 50 minutes, so tha...

Embodiment 3

[0056] Raw material formula (mass ratio, part): EVA resin (190 ℃ * 2.16kg melt mass flow rate = 1.0g / 10min, VAc content = 18wt%) 70, POE resin (190 ℃ * 2.16kg melt mass flow rate = 3.0g / 10min, octene content=30wt%) 5, LDPE resin (190 ℃ * 2.16kg melt mass flow rate=0.5g / 10min) 4, decabromodiphenylethane (purity 99%) 20 (particle size The most probable distribution of 1.5 μm and 2.0 μm two kinds of particles are 10 and 10), rutile titanium dioxide 1 (the most probable distribution of particle size is 0.5 μm), zinc stearate 0.8, PS resin content 30wt% surface coating Coating modified ultra-high molecular weight polytetrafluoroethylene 1.0, antioxidant B215 0.3.

[0057] Preparation process: ① PTFE surface coating modification: add 1000 mL of distilled water into a three-necked flask equipped with a stirrer, and the number average molecular weight is 4.5×10 6 , 70 grams of ultra-high molecular weight polytetrafluoroethylene particles with a particle size of 500 μm, 30 grams of gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com