Organic composite warm asphalt mixture and preparation method thereof

A warm-mix asphalt and mixture technology, applied in the field of road engineering asphalt, can solve the problems of high-temperature performance and water stability reduction, unfavorable road performance of asphalt mixture, cumbersome preparation process, etc., to reduce the temperature of mixing and compaction , low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention also provides a preparation method for the above-mentioned organic composite warm-mix asphalt mixture, comprising the steps of:

[0021] (1) Put the aggregate heated to 135-145°C into the mixing tank in proportion;

[0022] (2) Add petroleum asphalt heated to 140-150°C into the mixing tank in proportion, and at the same time, spread the organic composite warm mix agent on the surface of petroleum asphalt for mechanical mixing, and the mixing time is 50-60s; among them, petroleum asphalt The mixing temperature with the aggregate is controlled at 130-140°C;

[0023] (3) Add mineral powder and inorganic fillers in proportion to the mixing tank for mechanical mixing, and the mixing time is 50-60s;

[0024] (4) Take the mixture obtained in step (3) out of the cylinder, and control the temperature at 125-135°C to obtain the organic composite warm asphalt mixture;

[0025] (5) The organic composite warm-mix asphalt mixture obtained in step (4) is compac...

Embodiment 1

[0032] (1) Heat 10058g of aggregate to 145°C and put it into the mixing tank in proportion;

[0033] (2) Heat 477g of petroleum asphalt to 150°C and add it into the above mixing tank in proportion, and at the same time, spread 15g of organic composite warm mix agent (stearic acid amide: oleic acid amide = 4:1) on the surface of the above petroleum asphalt Carry out mechanical mixing, the mixing time is 50s, and the mixing temperature is controlled at 140°C;

[0034] (3) Add 155g of mineral powder and 155g of slaked lime in proportion to the above mixing tank for mechanical mixing, and the mixing time is 50s;

[0035] (4) Take the mixture obtained in step (3) out of the cylinder, and control the temperature at 135°C to obtain an organic composite warm asphalt mixture;

[0036] (5) Compact the organic composite warm-mix asphalt mixture obtained in step (4), and control the compaction temperature at 130°C.

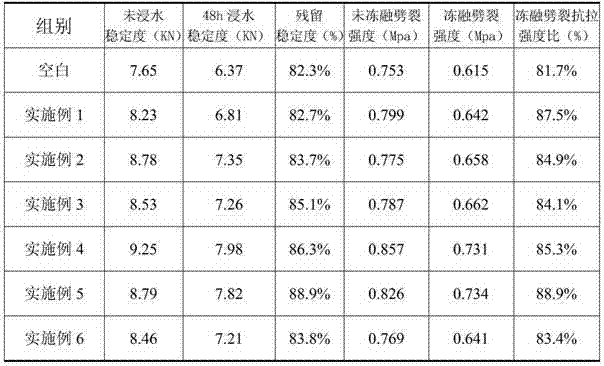

[0037] The specific technical indicators of the obtained organic compo...

Embodiment 2

[0039] (1) Heat 10065g of aggregate to 145°C and put it into the mixing tank in proportion;

[0040] (2) Heat 478g of petroleum asphalt to 140°C and add it into the above mixing tank in proportion, and at the same time spread 20g of organic composite warm mix agent (ethylene bis stearamide: ethylene bis oleic acid amide = 3:2) Sprinkle the surface of the above-mentioned petroleum asphalt for mechanical mixing, the mixing time is 50s, and the mixing temperature is controlled at 135°C;

[0041] (3) Add 158g of mineral powder and 158g of slaked lime in proportion to the above mixing tank for mechanical mixing, and the mixing time is 60s;

[0042] (4) Take the mixture obtained in step (3) out of the tank, and control the temperature at 130°C to obtain an organic composite warm asphalt mixture;

[0043] (5) Compact the organic composite warm-mix asphalt mixture obtained in step (4), and control the compaction temperature at 125°C.

[0044] The specific technical indicators of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com