High-dispersivity modified calcium carbonate for color masterbatches and preparation method thereof

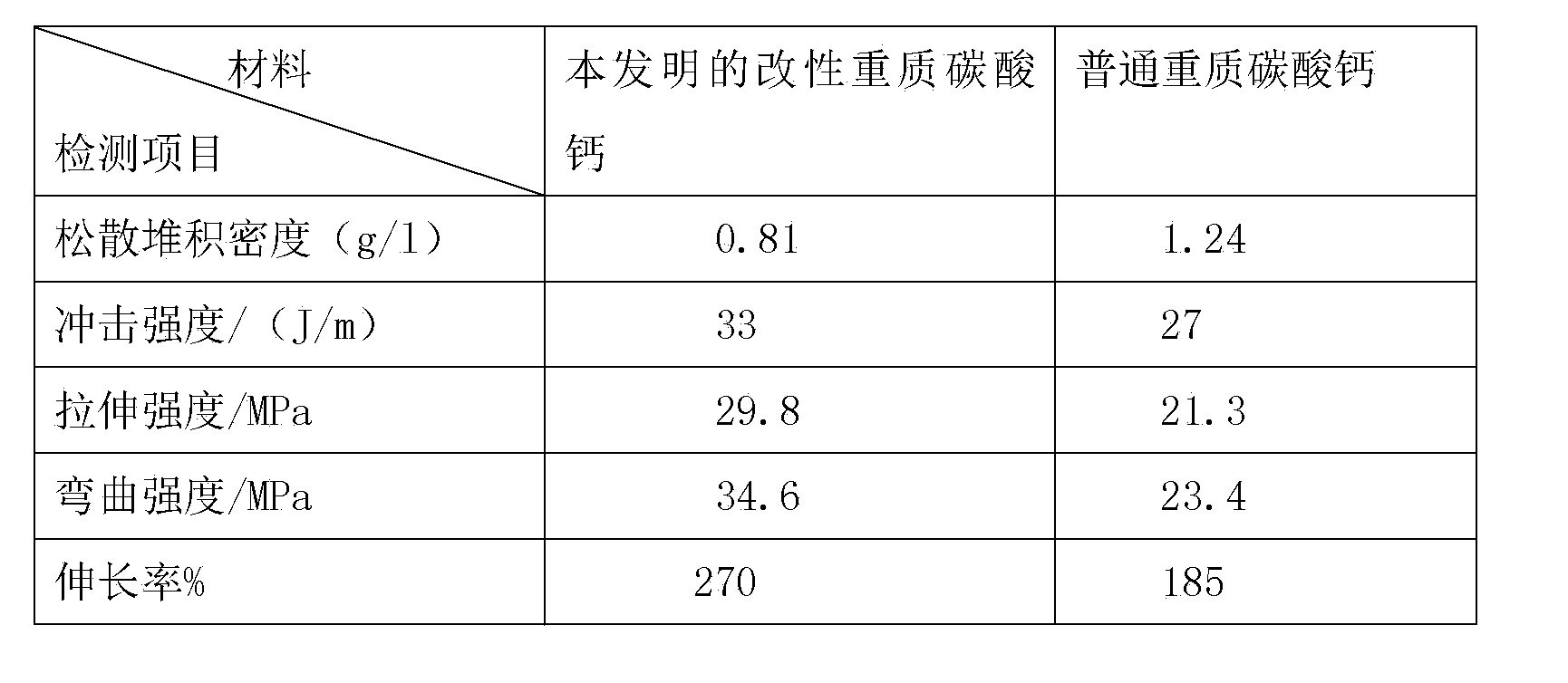

A technology with high dispersion and color masterbatch, which is applied in the treatment of dyed high-molecular organic compounds, chemical instruments and methods, and dyed low-molecular organic compounds. It can solve the problems of performance degradation of composite materials, two-phase interface defects, and matrix bonding force. Weakness and other problems, to achieve the effect of increasing the amount of addition, uniform particle size, good dispersion and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A preparation method for highly dispersive modified calcium carbonate for color masterbatch,

[0012] First weigh heavy calcium carbonate 100, diffusing agent NNO 0.3, ferrocene 0.2, bisphenol A polycarbonate 0.3, rutile titanium dioxide 1, talcum powder 0.5, white oil 0.1, methyl phenyl Silicone oil ethylene bisoleic acid amide 0.6, high-density linear polyethylene 1, stearic acid 0.3, paraffin wax 1, isopropyl tris(dioctyl pyrophosphate acyloxy) titanate 3, prepared according to the following steps:

[0013] First, dry the heavy calcium carbonate at 90-100°C until the water content is less than 0.5%, and then add it to the high-speed mixer; mix the diffusing agent NNO, ferrocene, bisphenol A polycarbonate, rutile titanium dioxide, Add talcum powder and white oil into a high-speed mixer, and stir at a speed of 800-1000 rpm for 3-5 minutes at 80-95°C; Linear polyethylene, stearic acid, paraffin, isopropyl tris (dioctyl pyrophosphate acyloxy) titanate are added to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com