LED display screen based on chip-on-board packaging technology and production method thereof

A technology of LED display screen and production method, which is applied in the directions of identification devices, electrical components, electrical components, etc., can solve the problems of limited heat dissipation of components, difficulty in preparing LED display screens with small dot pitch, etc. The effect of high application value and less glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

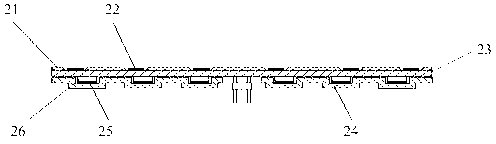

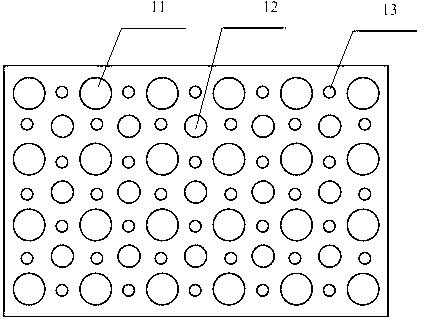

[0022] An embodiment of the present invention is a method for producing LED display screens based on COB technology, which includes the following steps.

[0023] S1. According to the target, the area of the display module is 0.01 to 1 square meters, and the dot pitch is 1 to 10 mm. According to the preset control method, the wiring is made into a PCB circuit board; the display module is the display unit, which is assembled into an LED display box. , and the LED display box is assembled into an LED display, or the display module is assembled into an LED display. For example, the control lines are wired in a series-parallel combination and a specific control method to make a PCB circuit board. Preferably, in S1, the PCB circuit board with an area of 0.06 to 0.6 square meters is produced; preferably, the PCB circuit board with an area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com