LED lampshade coating and coating method thereof

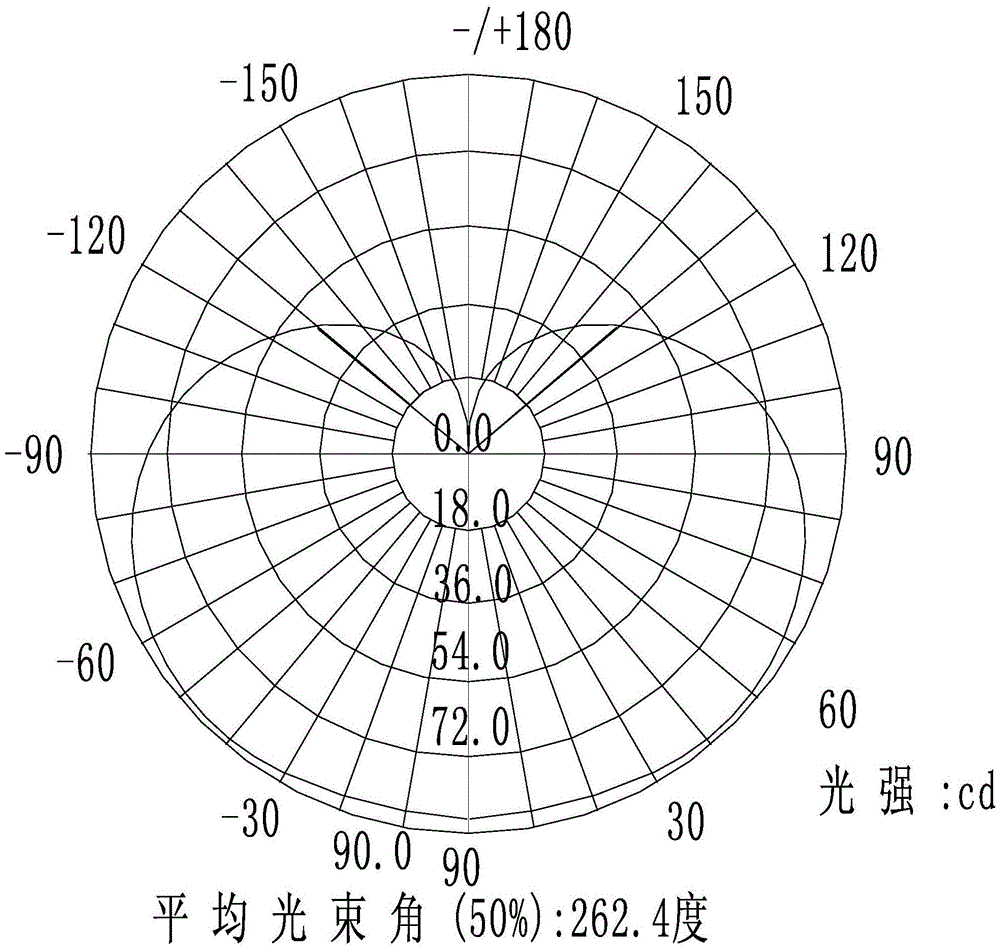

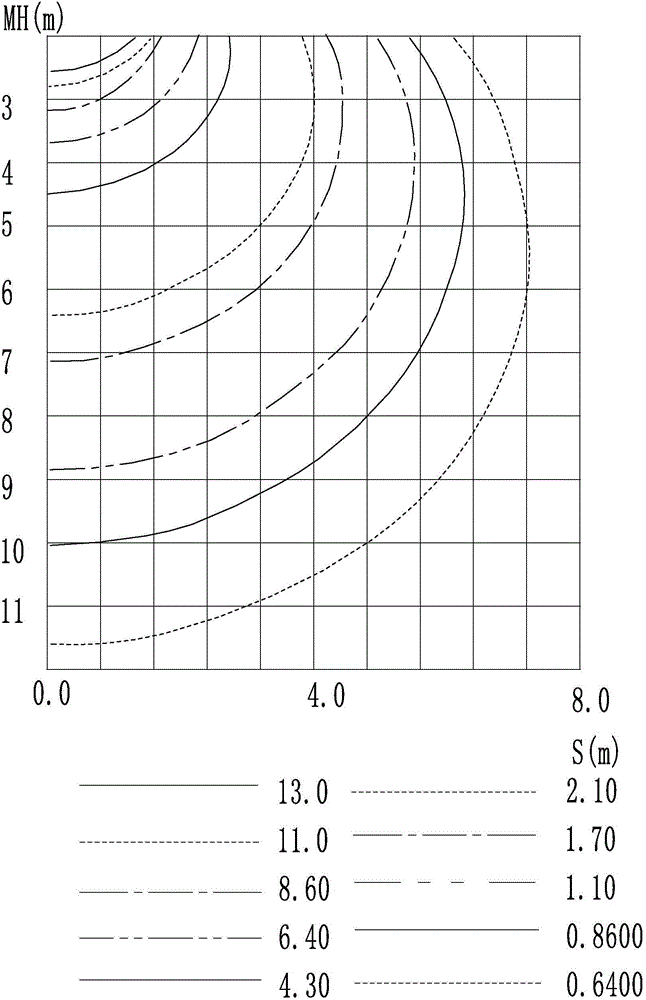

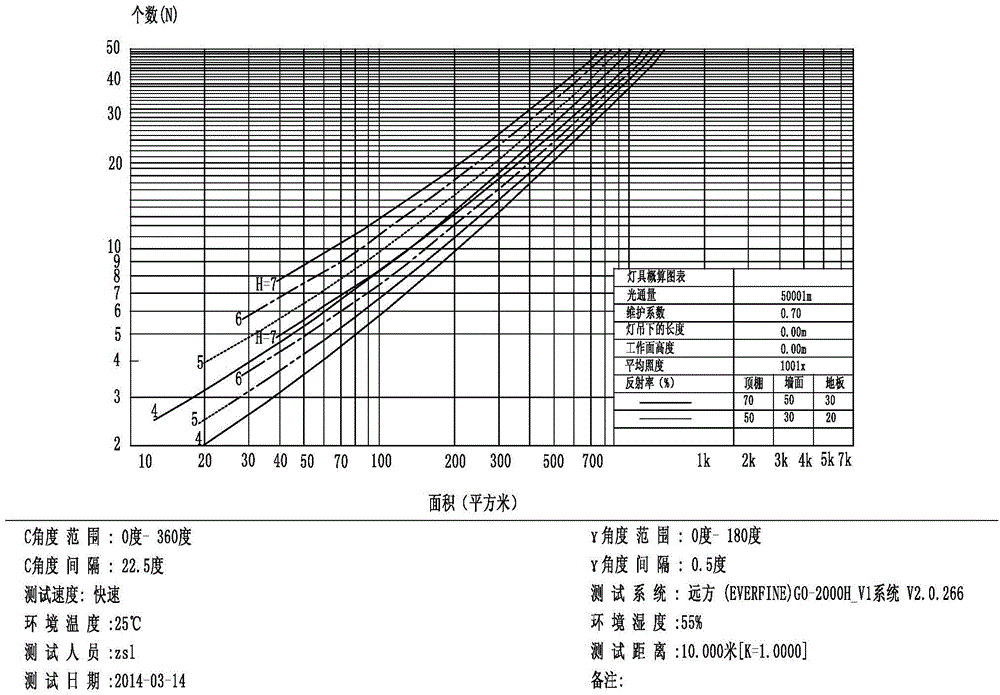

A technology of LED lampshades and coatings, applied in lampshades, polyester coatings, epoxy resin coatings, etc., can solve the problems of small luminous angle, affecting aesthetics, low light transmittance, etc., and achieve the effect of large luminous angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0026] A kind of LED lampshade paint of this embodiment is made up of resin, silicon dioxide, titanium dioxide, aluminum dioxide, fluorescent powder, calcium carbonate, barium sulfate and diffusing powder; The mass share of each component is: resin 200-500, two Silicon oxide 5-30, titanium dioxide 3-50, aluminum dioxide 2-20, fluorescent powder 100-450, calcium carbonate 3-25, barium sulfate 8-40, diffusion powder 10-80; each component is above 300 mesh of powder. The resin therein can be one or more combinations of alkyd resin, acrylic resin, polyester resin, epoxy resin and silicone resin, preferably acrylic resin. Each component is a powder of more than 350 mesh.

[0027] The LED lampshade paint of this embodiment, on the basis of the previous technical solution, can also specifically be that the mass proportion of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com