LED fluorescent lamp tube and method for manufacturing same

A technology of LED fluorescent lamp and LED light source, which is applied in the direction of light source, electric light source, light source fixation, etc., can solve the problems of glass tube being fragile, failing to reach the lighting angle, and high cost, and achieve the effect of reducing production cost and increasing the lighting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

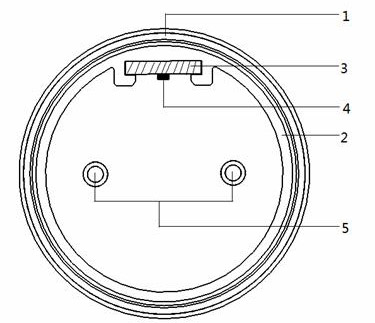

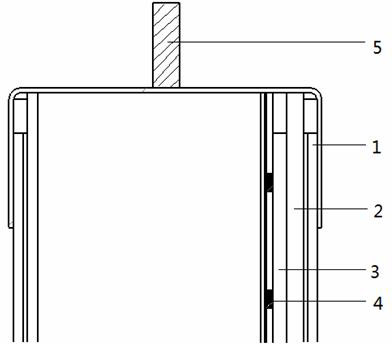

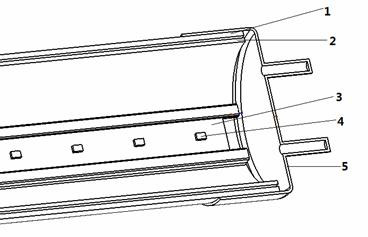

[0023] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

[0024] like figure 1 , 2 , The LED fluorescent tube shown in 3 and 4 includes a glass tube 1, a plastic tube 2, a circuit board 3, an LED light source 4, and two lamp caps 5, and the plastic tube 2, the circuit board 3, and the LED light source 4 are all packaged in the glass tube 1 Inside, two lamp caps 5 are installed at both ends of the glass tube 1 respectively. The LED light source 4 is fixed on the circuit board 3, the plastic pipe 2 is provided with a card slot, the circuit board 3 is fixed in the plastic tube 2 through the card slot, and the circuit board 3 divides the cylindrical plastic tube 2 into two arc-shaped cross-sections cavity.

[0025] The position of the circuit board 3 in the plastic tube 2 can be adjusted so that the ratio of the cross-sectional areas of the two cavities is 1:0.01-1:1, and the area ratio of the two cross-sectional areas is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com