A wood slicer automatic filling device

An automatic filler and slicer technology, applied in the manufacture of thin wood chips, wood processing appliances, manufacturing tools, etc., can solve the problems of easily scratching the conveyor belt, affecting the cutting accuracy, poor smoothness of wood, etc., to improve the service life, Reduce the consumption of resources and avoid the effect of pulling damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

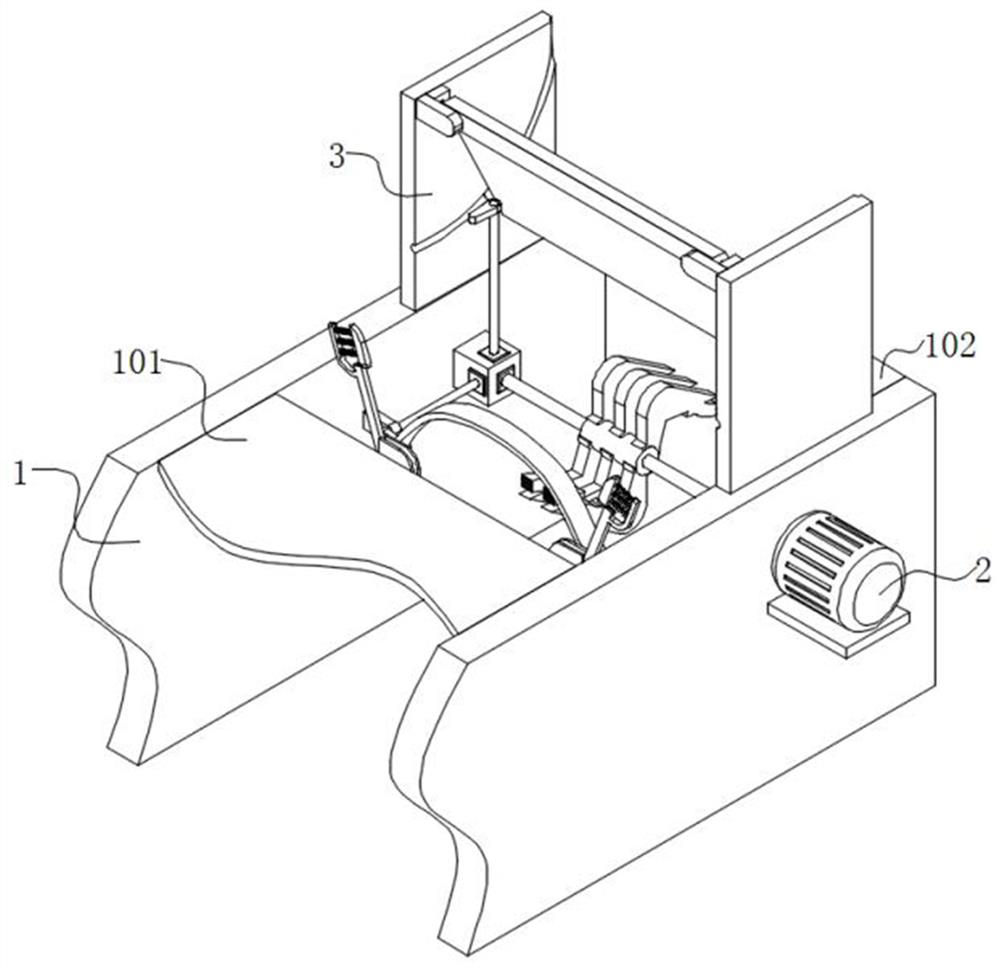

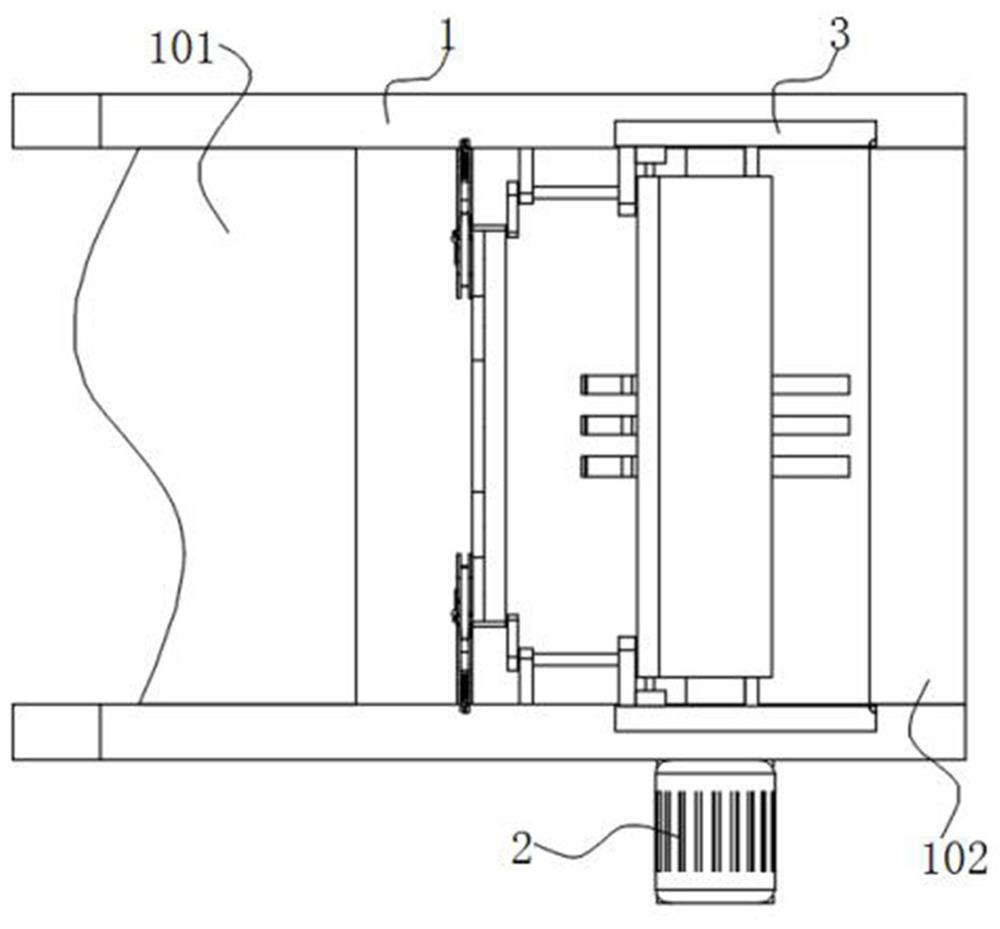

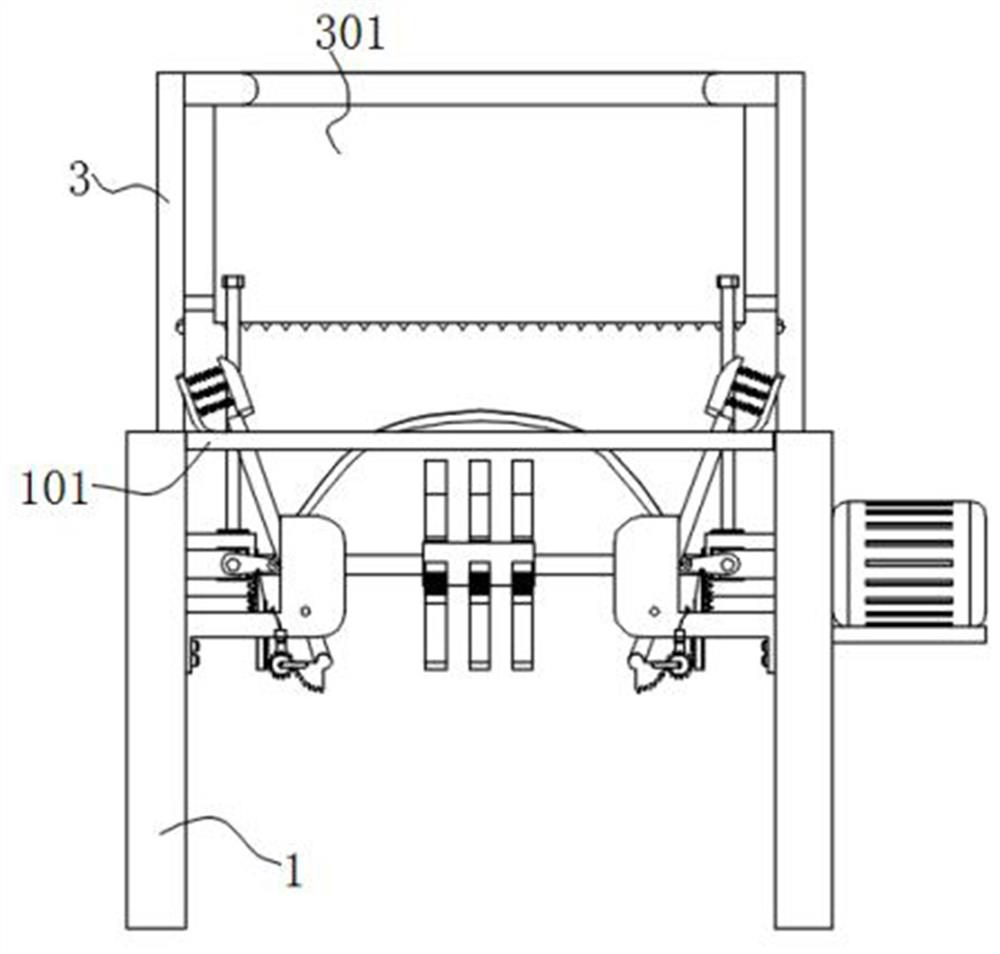

[0049] Example 1: as Figure 1 to Figure 4 As shown in the figure, the automatic filling device of the wood slicer in this embodiment includes a machine 1, a conveyor belt body 101 installed on the top of the machine 1, and a slice feeder 102 at the edge of the machine 1. One side of the machine 1 A servo motor 2 is installed on the surface, a steering gear box 203 is installed on the inner surface of the machine table 1, and a drive shaft 204 is installed between the two sets of steering gear boxes 203. One end of the drive shaft 204 is connected to the servo motor 2 The output shaft of the steering gear box 203 is connected to the output shaft of the steering gear box 203 on one side. A feeding mechanism is installed on the shaft, and a filling mechanism is installed on the drive shaft 204 .

[0050] Specifically, as Figure 5 As shown, the filling mechanism includes a conveying push frame 201 and an anti-skid block 202. The conveying push frame 201 is installed at the mid...

Embodiment 2

[0052] Embodiment 2: on the basis of embodiment 1: further, such as Figure 5 , Image 6 and Figure 12 As shown, the tear-proof mechanism includes a first deflection block 4 and a ductile metal plate 401 , the output shaft of one side of the steering gear box 203 is installed with the first deflection block 4 , and the movable parts of the first deflection block 4 are jointly installed with a first deflection block 4 . Ductile metal plate 401 .

[0053] At work: as Figure 5 , Image 6 and Figure 12 As shown, on the basis that the servo motor 2 drives the drive shaft 204 to rotate, the rotation of the drive shaft 204 drives the transmission of the helical gear inside the steering gear box 203, and the helical gear on the side of the steering gear box 203 is installed with a first deflection block 4 through the rotating shaft. , that is, the rotation of the drive shaft 204 drives the first deflection block 4 to rotate synchronously, and the rotation of the drive shaft 20...

Embodiment 3

[0054] Embodiment 3: on the basis of embodiment 2: further, such as Figure 7 and Figure 8 As shown, the position adjustment mechanism includes an assembly frame 5, a wedge tooth plate 6, a guide gear 7, a wood adjusting member 501 and a movable part. The surface of the machine table 1 on one side of the first deflection block 4 is installed with an assembly frame 5. The assembly frame The surface of 5 is provided with a chute, the inside of the chute is slidably installed with a wedge tooth plate 6, the bottom end of the assembly frame 5 is installed with a guide gear 7, and the bottom end of the assembly frame 5 is also installed with a wood adjusting piece 501 through the rotating shaft, the wedge The top of the toothed plate 6 is located on the rotation path of the first deflection block 4, and the toothed wedge plate 6 is used in conjunction with the guide gear 7, the guide gear 7 is used in conjunction with the wood adjusting piece 501, and the movable part is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com