Novel LED (light emitting diode) light source and bulb manufactured by using same

A technology of LED light source and LED chip, applied in the field of LED light source, can solve the problems of small light-emitting angle of the light source, poor heat dissipation effect of the light source, and poor insulation and withstand voltage characteristics of the substrate, so as to improve the uniformity and softness of the light output, and be widely popularized. Use value, the effect of good insulation and withstand voltage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

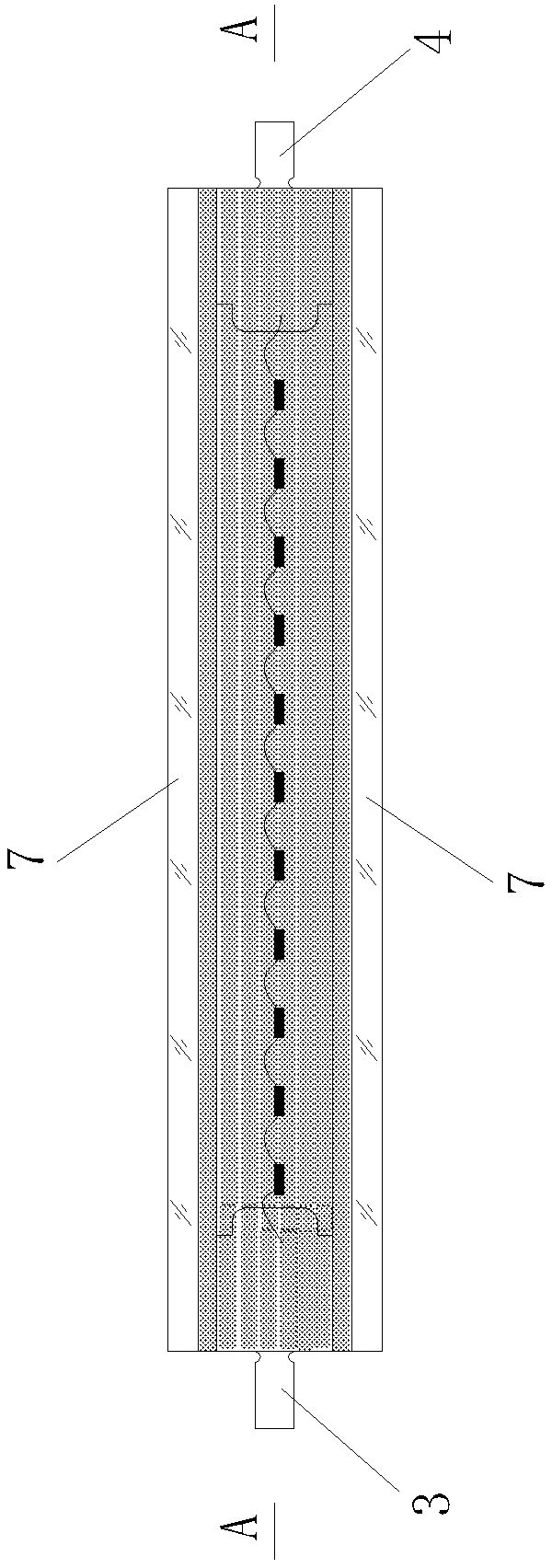

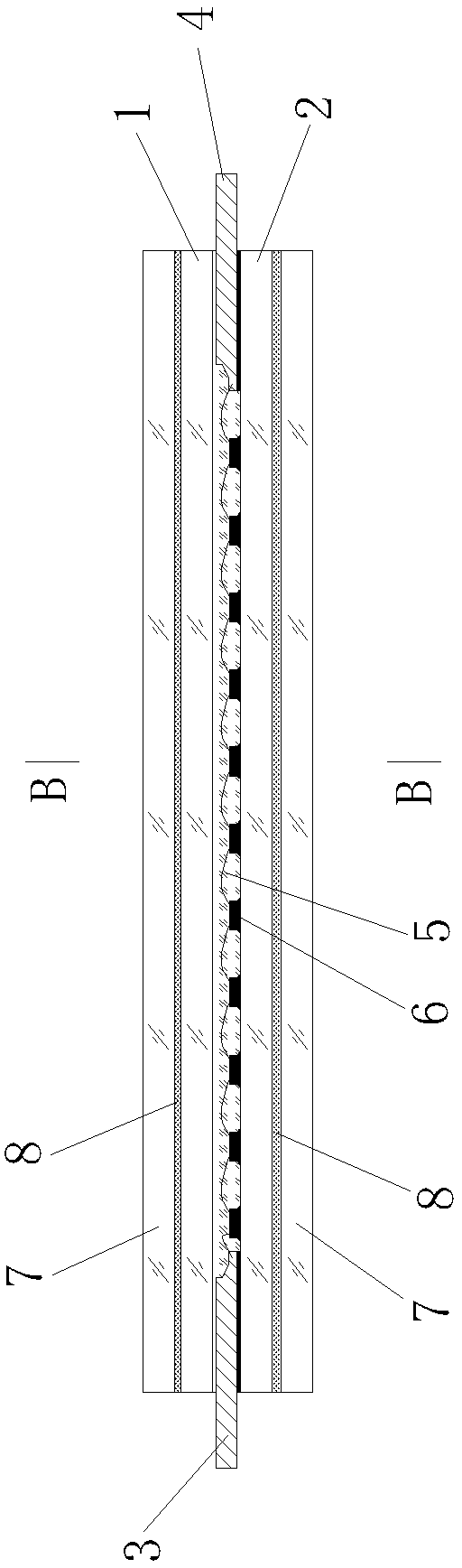

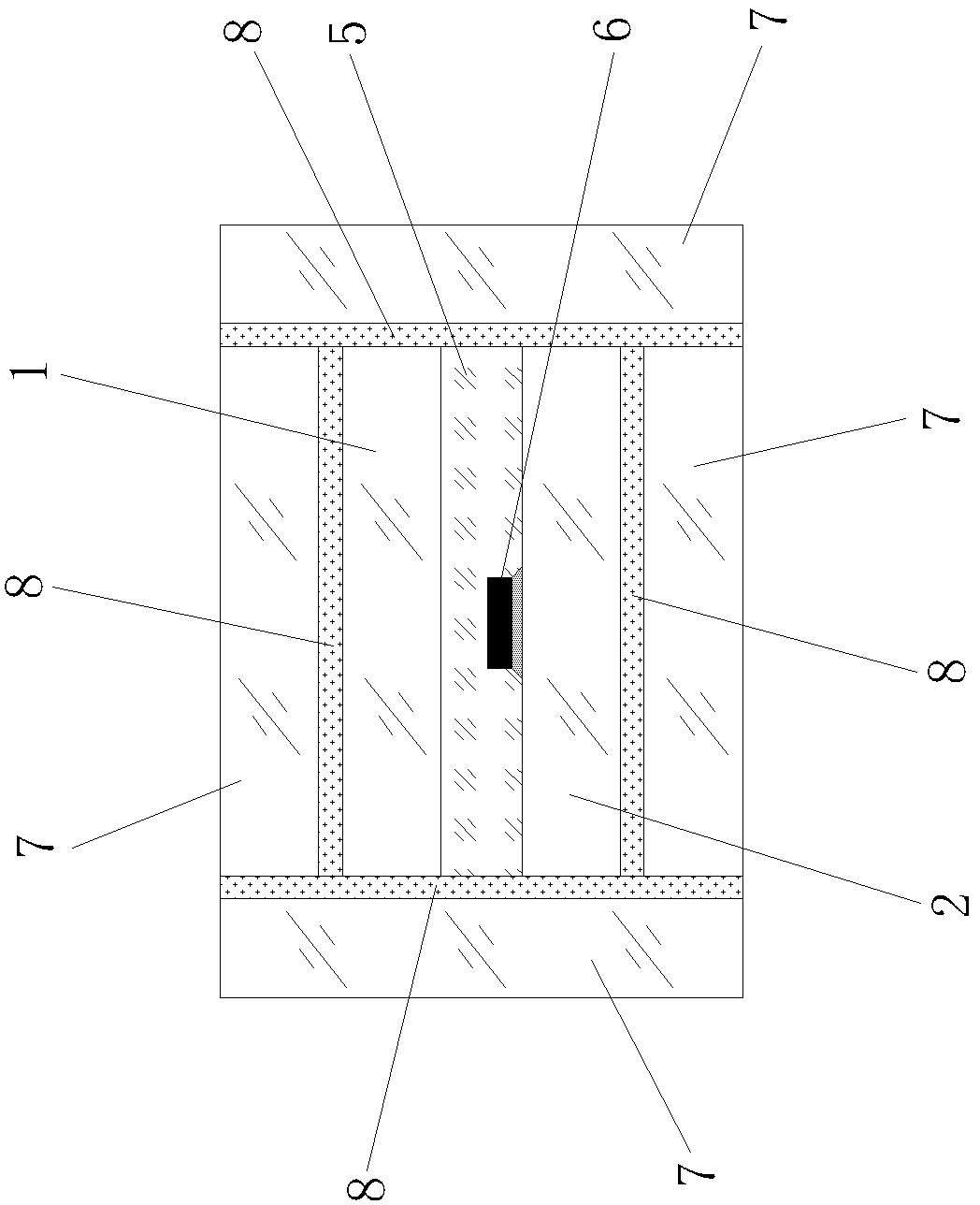

[0024] Figure 1 to Figure 3 As shown, a new type of LED light source includes an upper glass substrate 1, a lower glass substrate 2, two external electrodes 3, 4, and a plurality of LED chips 6 are packaged with transparent glue 5 between the upper and lower glass substrates 1, 2. , the two external electrodes 3, 4 protrude between the upper and lower glass substrates 1, 2 and respectively connect with the two electrodes formed by serial connection of multiple LED chips 6;

[0025] The upper surface of the upper glass substrate 1 and the lower surface of the lower glass substrate 2 are covered with a protective glass plate 7 , and a fluorescent material layer 8 is coated between the protective glass plate 7 and the upper surface of the upper glass substrate 1 and the lower surface of the lower glass substrate 2 .

[0026] The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com