LED three-dimensional optical system design method and optical system with given luminous intensity distribution

A technology of illuminance distribution and three-dimensional optics, which is applied in the field of non-imaging optics, and can solve the problems that the refraction scheme is not easy to fully utilize the energy of the light source, increases the cost, and cannot guarantee the uniformity of illuminance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

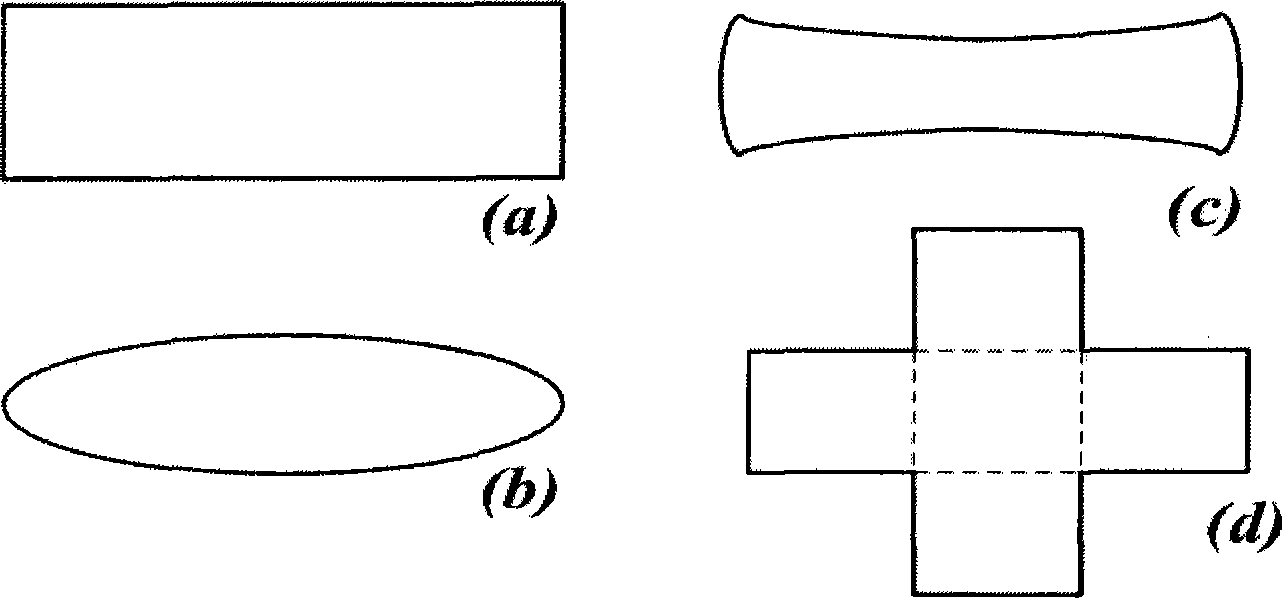

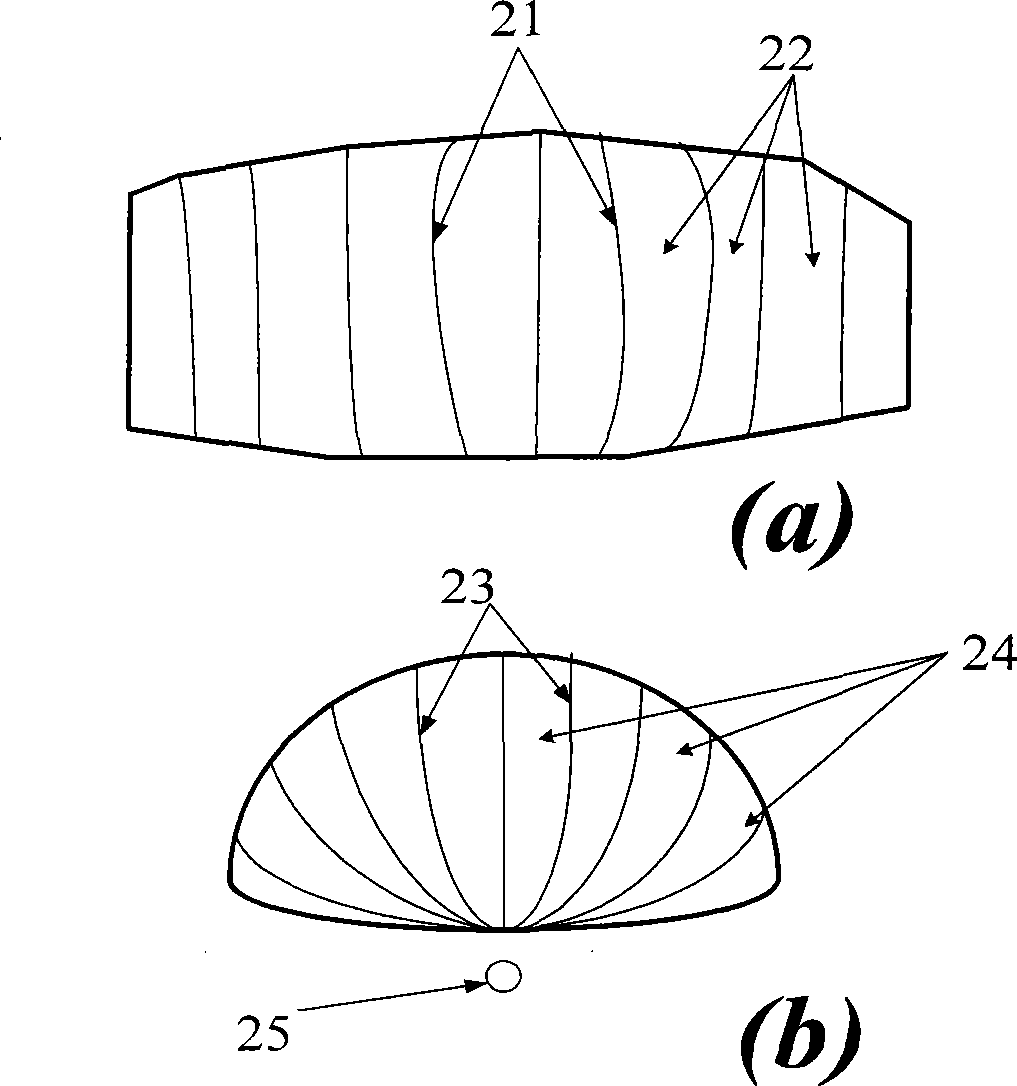

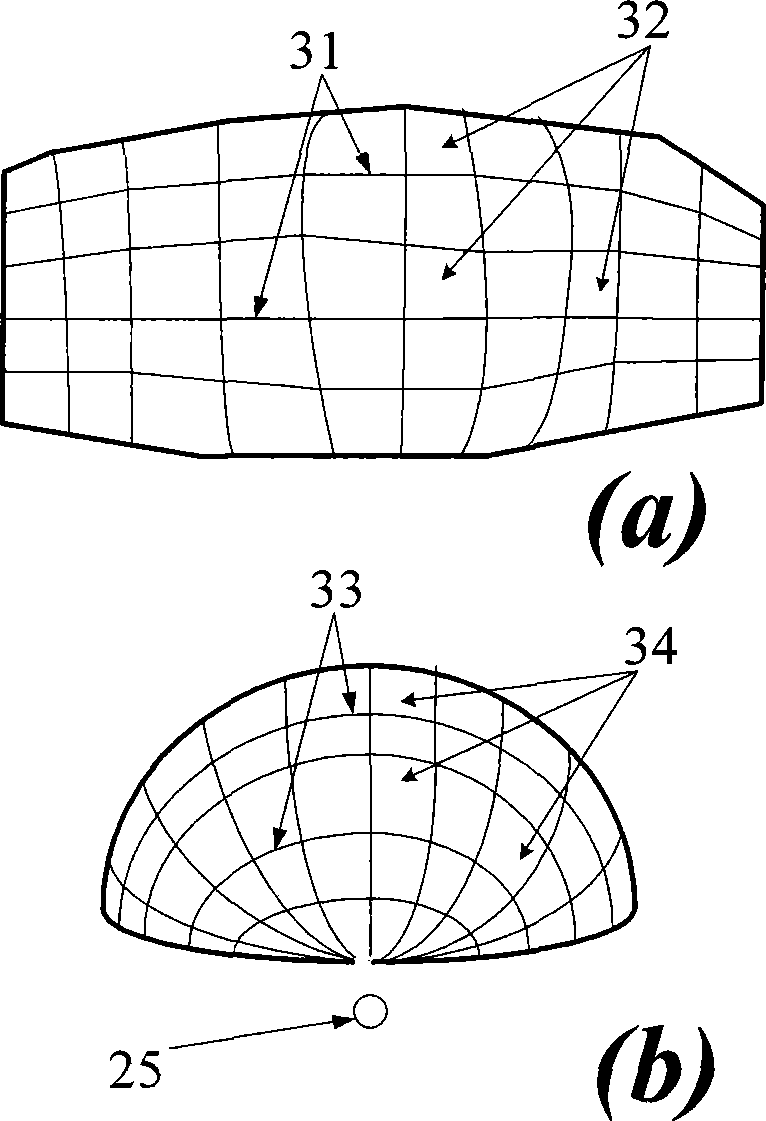

[0049] As a new type of lighting source, LED is small in size and can be approximately regarded as a point light source in the package lens design. The lens design method proposed in the present invention is based on the principle of energy conservation, divides the energy of the illuminance plane and the energy of the point light source according to the plane coordinates and direction angles, and makes the energy one-to-one correspondence. In this division process, the algorithm in the present invention firstly separates the energy of the illuminance plane according to the major axis and the minor axis, and at the same time separates the energy of the light source according to the corresponding directions, and calculates the corresponding relationship of energy in the two axial directions; then Establish respective discrete points in the coordinates of the illuminance plane and the coordinates of the angle direction of the light source and correspond them one by one; then, acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com