Lamp filament LED (Light-Emitting Diode) bulb

A technology of LED bulbs and filaments, applied in lighting and heating equipment, point light sources, lighting devices, etc., to achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

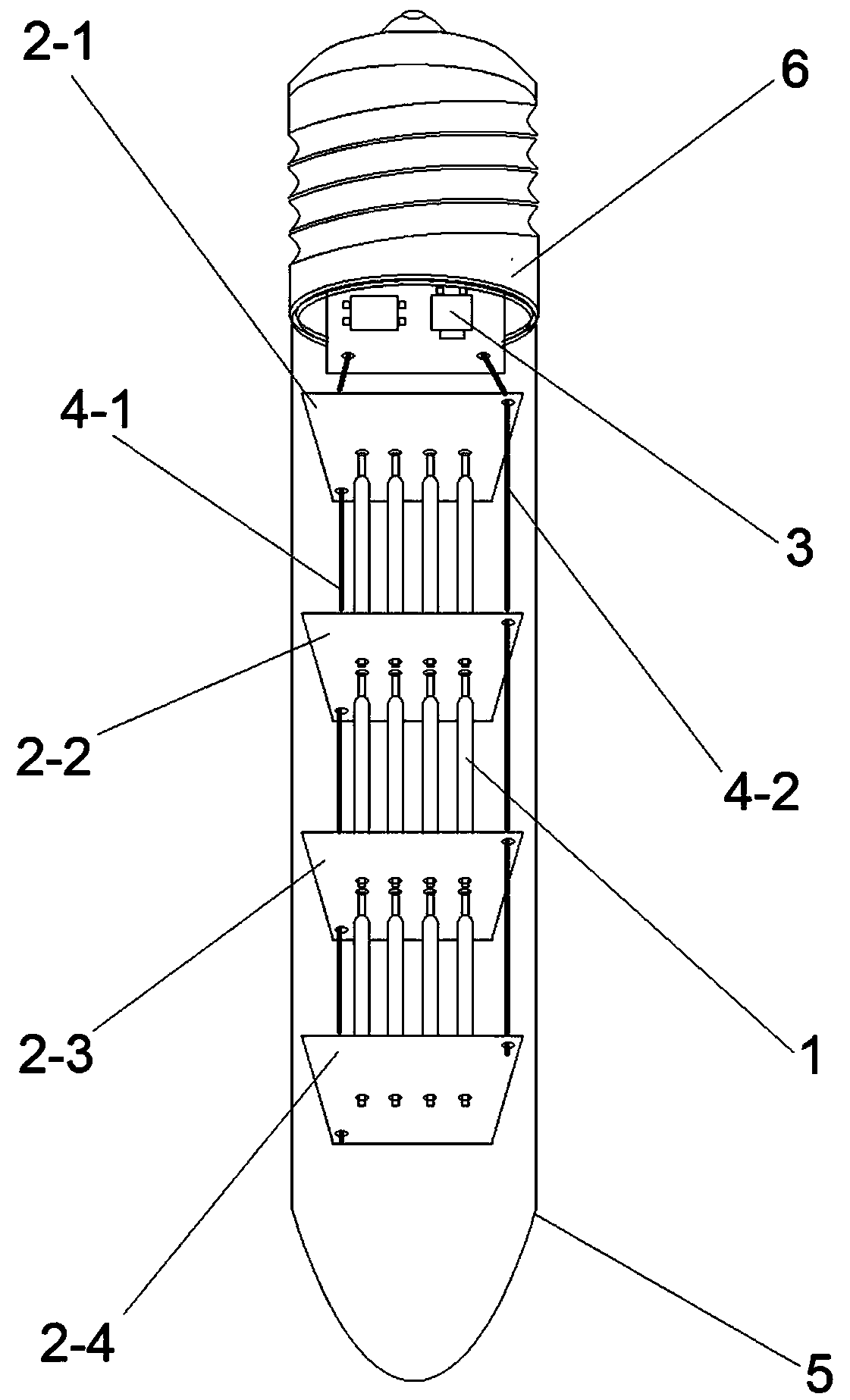

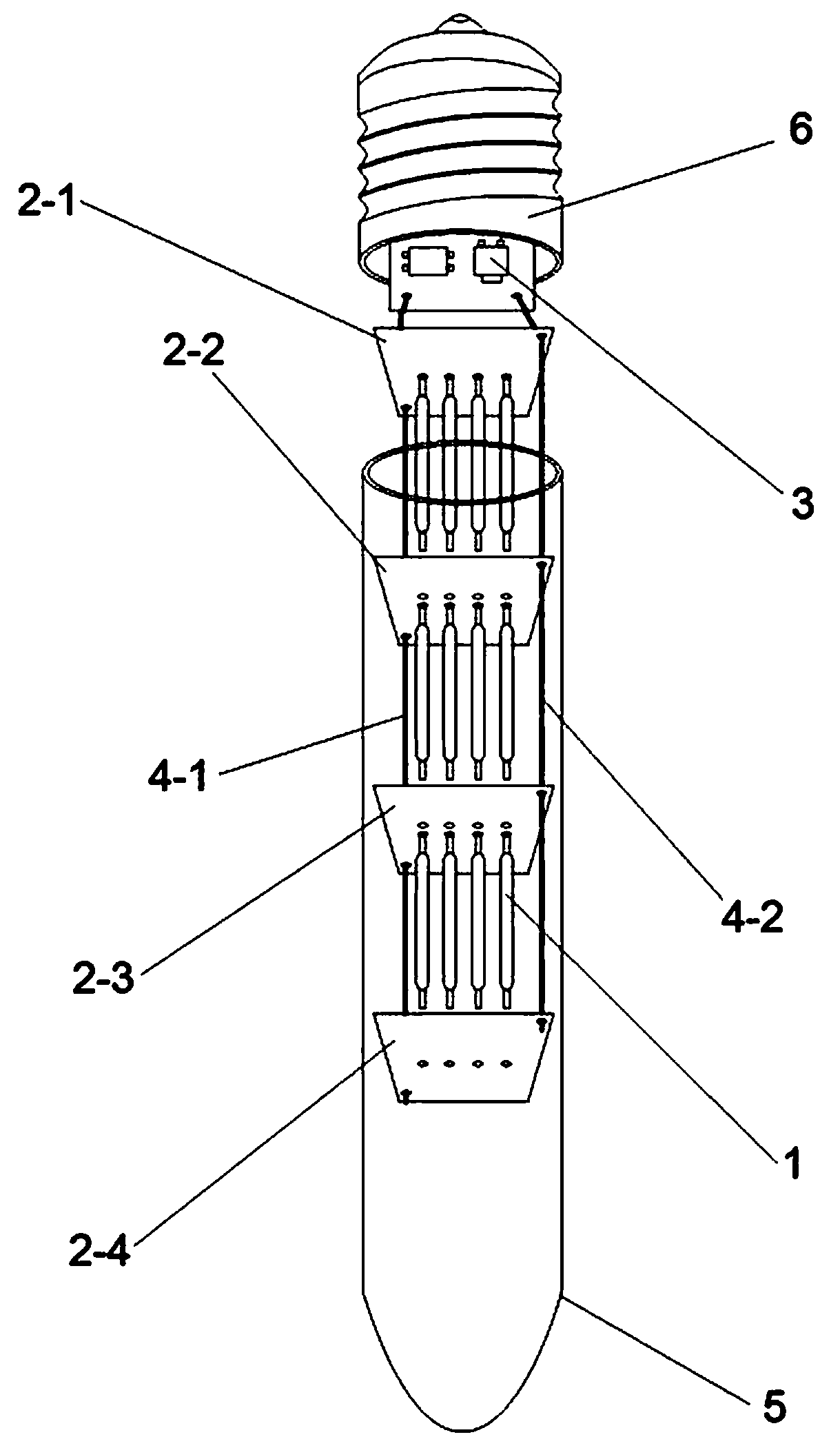

[0032] The specific implementation manner of the present invention will be introduced below in conjunction with the accompanying drawings.

[0033] Such as figure 1 and figure 2 As shown, a filament LED light bulb of the present invention is composed of a filament LED1, a circuit board 2-1, a circuit board 2-2, a circuit board 2-3, a circuit board 2-4, a driving power supply 3, a wire 4-1, and a wire 4 -2. The lampshade 5 and lamp holder 6 are assembled. Place the driving power supply 3 in the lamp cap 6, connect one or more circuit boards 2-1, circuit board 2-2, and circuit board 2 in series with the wire 4-1 and wire 4-2 connected to the output end of the driving power supply 3 -3 and circuit board 2-4, one or more filament LED1 is welded on each circuit board 2-1, circuit board 2-2, circuit board 2-3 and circuit board 2-4, through circuit board 2- 1. The circuits on the circuit board 2-2, the circuit board 2-3 and the circuit board 2-4 make one or more filament LED1 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com