Large-angle omnidirectional lighting LED (light emitting diode) lamp

A LED lamp and large-angle technology, which is applied to lighting devices, lighting and heating equipment, and parts of lighting devices. The effect of large luminous angle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

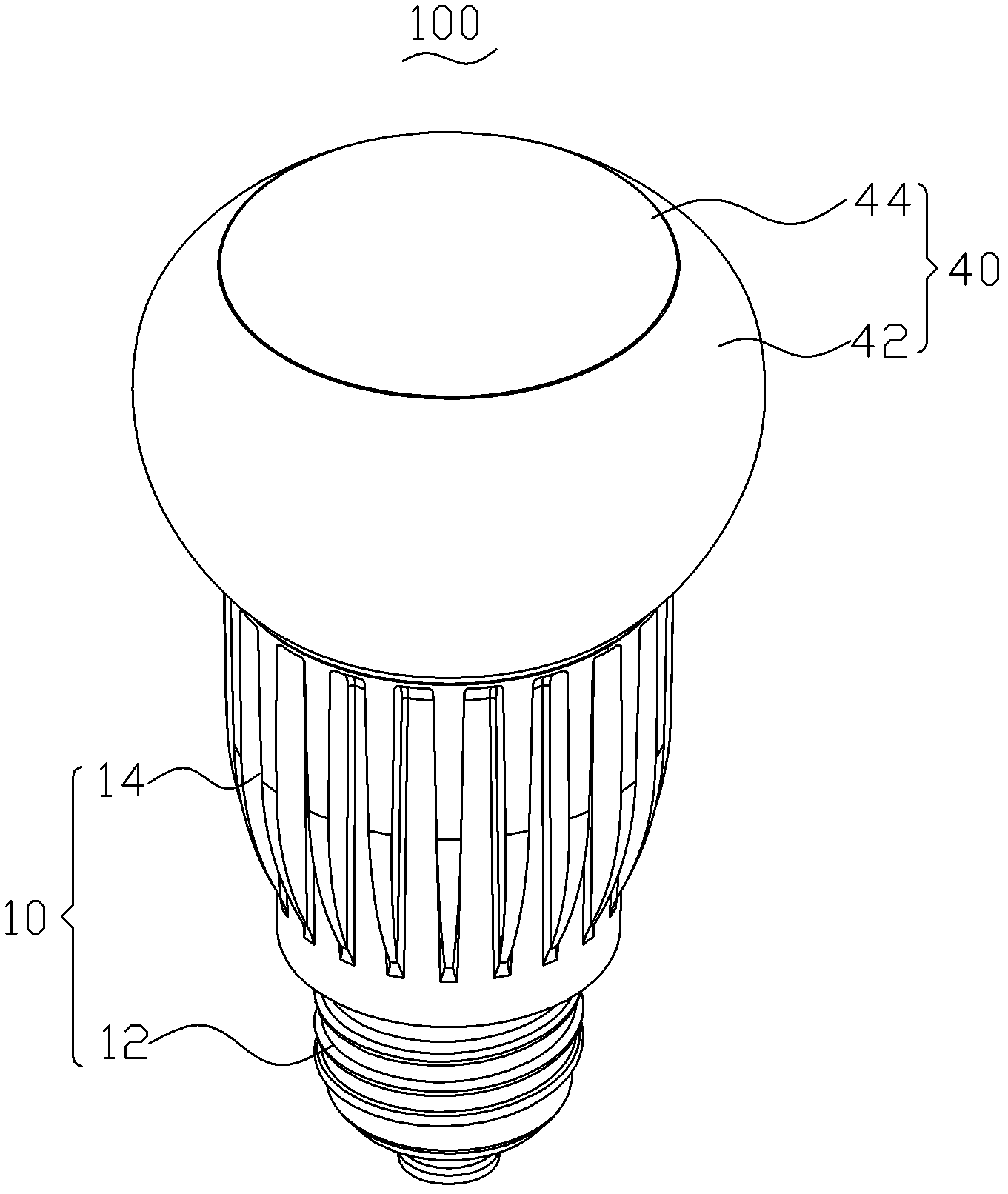

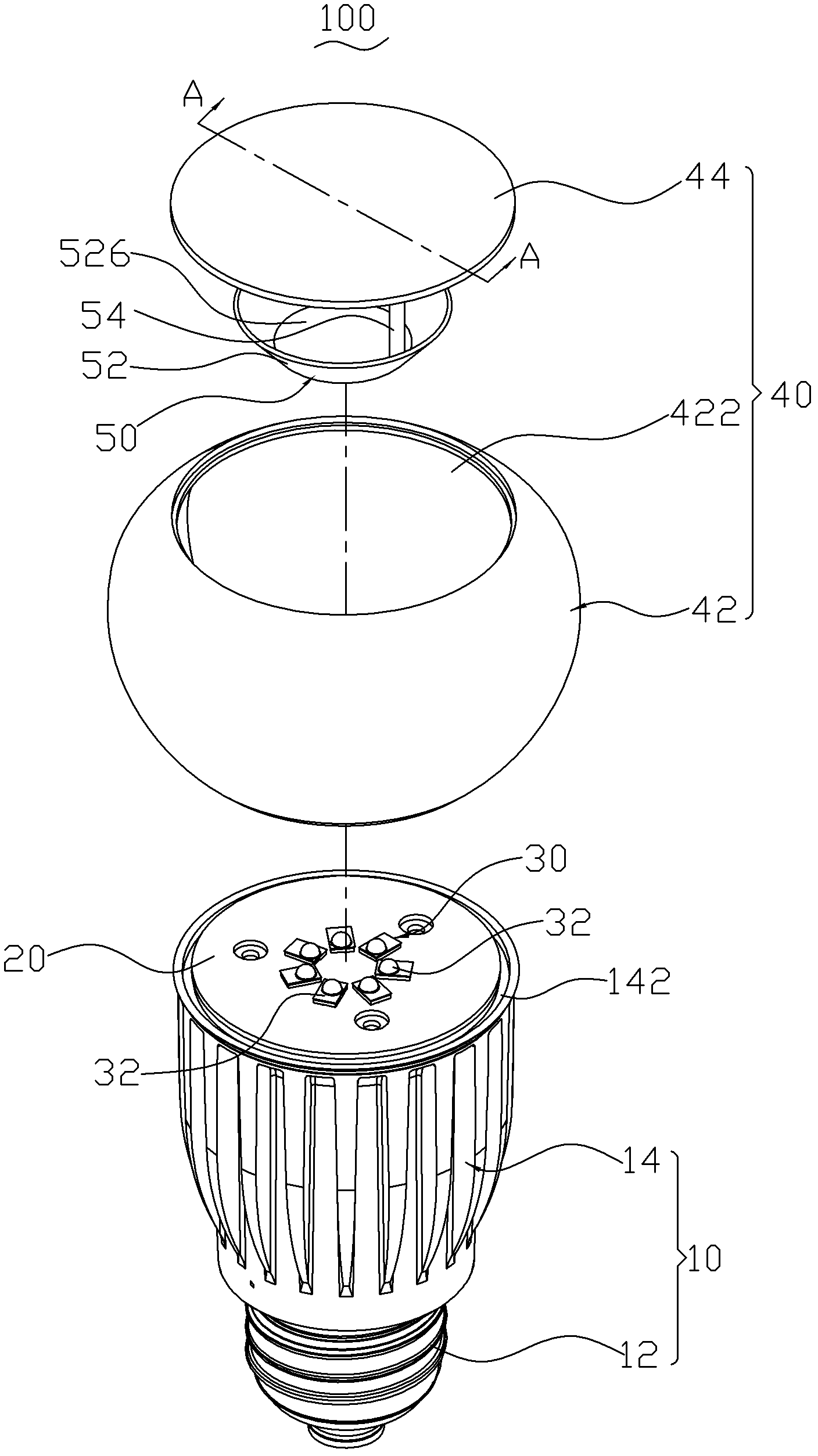

[0016] For the large-angle omnidirectional lighting LED lamp 100 of the first embodiment of the present invention, please refer to Figure 1 to Figure 3 .

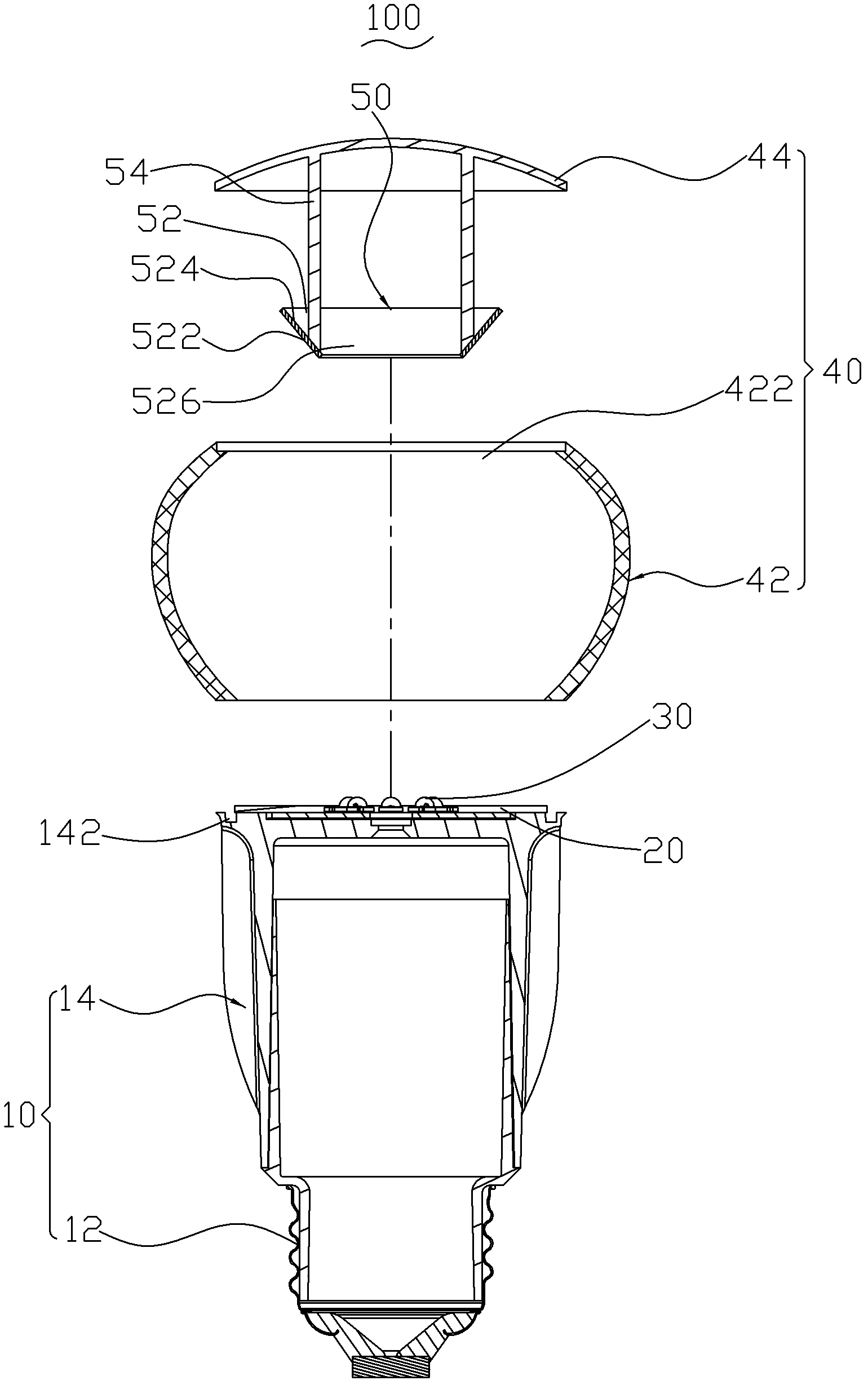

[0017] Please refer to figure 1 and figure 2 , the large-angle omnidirectional lighting LED lamp 100 mainly includes a lamp head body 10 , a heat transfer substrate 20 , a light emitting unit 30 , a bulb shell 40 and a reflection unit 50 .

[0018] Please refer to figure 2 and image 3 , the lamp body 10 includes a lamp base 12 and a heat sink 14 . The heat sink 14 is a traditional finned heat sink, and its bottom end is fixed on the lamp holder 12 . A top end of the radiator 14 defines an annular groove 142 . The heat transfer substrate 20 is a disc-shaped structure, which is disposed on the top of the lamp body 10 , that is, the top of the heat sink 14 . The light emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com