Industrialized building partition wall beneficial for structural seismic resistance

A beneficial and architectural technology, applied in the direction of buildings, building types, building components, etc., can solve the problems of unfavorable structure anti-seismic, affect the local stiffness of the main structure, etc., achieve the effect of short construction period and increase earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

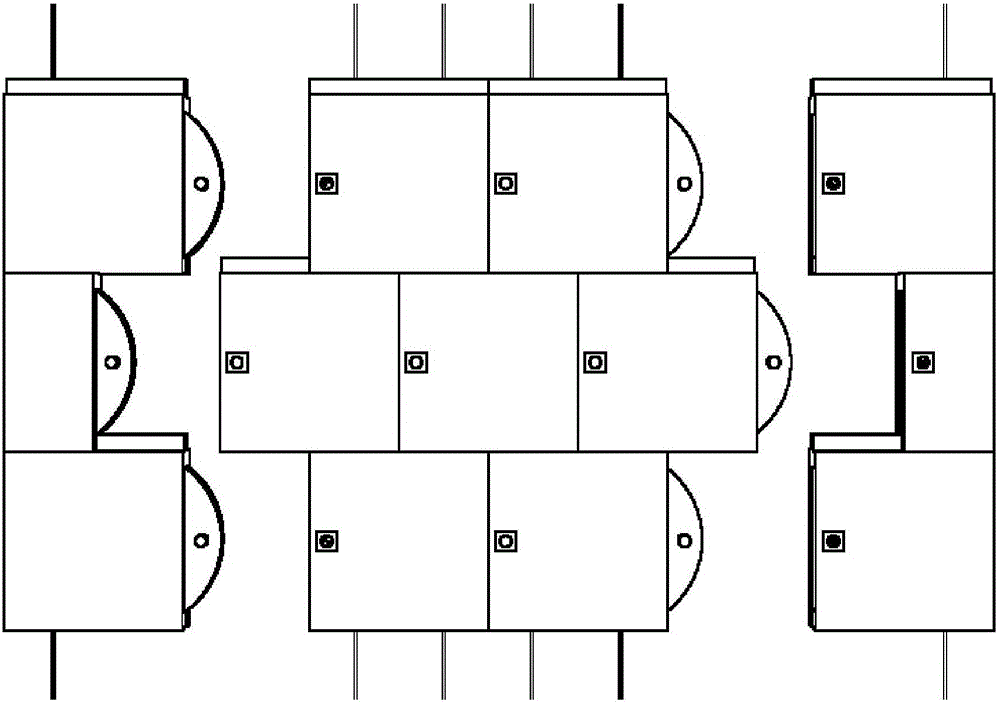

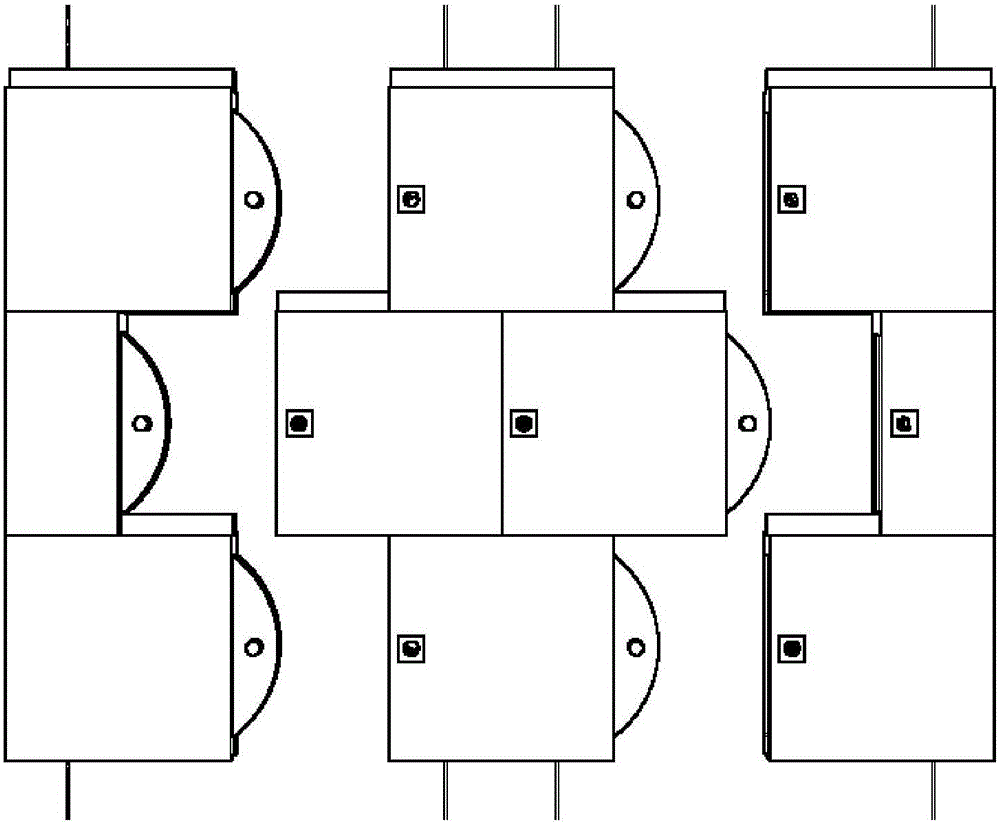

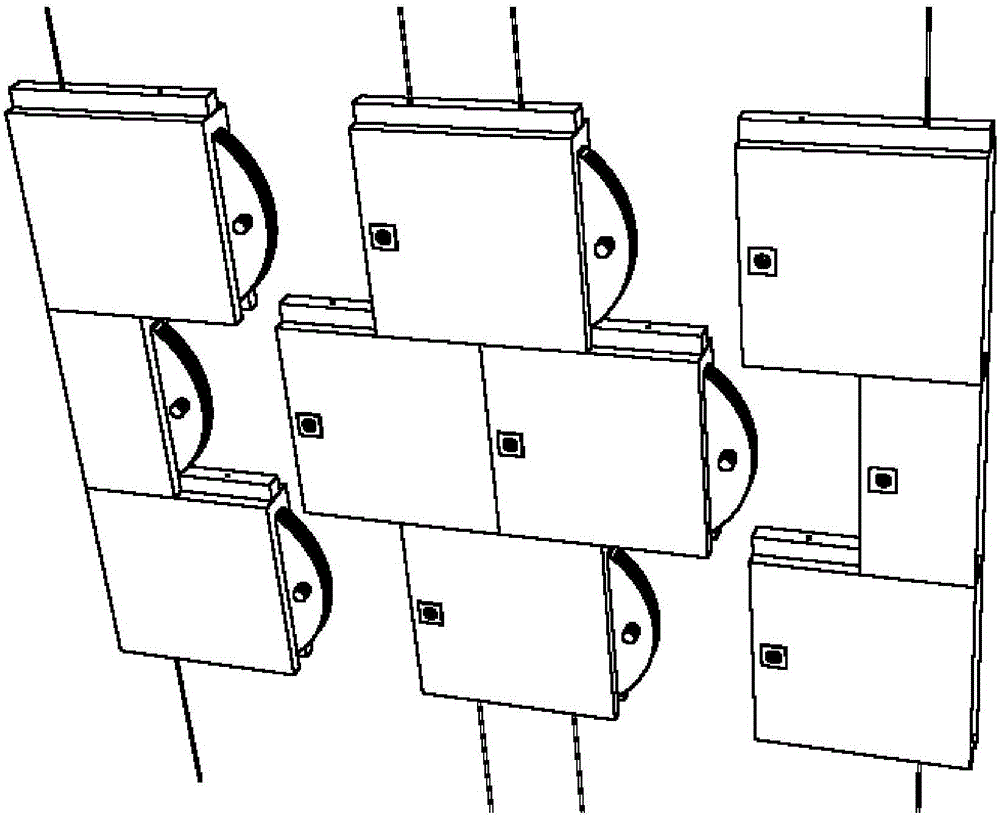

[0031] Such as Figure 4 As shown in A, 4B and 4C, 5A and 5B, 6A and 6B, an industrialized building partition wall beneficial to structural earthquake resistance is formed by splicing a plurality of prefabricated wall panels, wherein one side of a prefabricated wall panel has an inner The floor arc is raised and can be spliced with the groove of another prefabricated wallboard, and can be fixed by bolt connection after splicing.

[0032] The prefabricated wall panels are preferably square.

[0033] The size of the above-mentioned prefabricated wall panels is preferably a multiple of 900 mm.

Embodiment 2

[0035] Such as figure 1 , 2 , 3, 4A, 4B and 4C, 5A and 5B, 6A and 6B show an industrialized building partition wall beneficial to the structure's earthquake resistance, which is formed by splicing a plurality of prefabricated wall panels, wherein one prefabricated wall panel The side has an inner arc protrusion, which can be spliced with another prefabricated wall panel groove, and can be fixed by bolt connection after splicing.

[0036] Among them, three prefabricated wall panels are integrated, including two square prefabricated wall panels and one rectangular prefabricated wall panel, forming a concave shape prefabricated wall panel, and there are three inner arc protrusions on the same side of the three prefabricated wall panels, It can be spliced with the other three integrated prefabricated wallboard grooves, and can be fixed by bolt connection after splicing.

[0037] The size of the above-mentioned prefabricated wall panels is preferably a multiple of 900 mm.

...

Embodiment 3

[0040] refer to Figure 9 As shown, on the basis of the solution in Embodiment 1 or 2, the size of the arc protrusion in the further preferred solution is preferably that the chord length H is 600 mm, and the chord height h is 200 mm.

[0041] The bolt is preferably arranged at the center of the arcuate protrusion, and its dimension is preferably D (diameter) = 24mm.

[0042] Preferably, the prefabricated wallboard reserves holes for prestressed steel strands vertically, that is, the steel strands can be stretched during installation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chord length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com