Film solar cell module and method for processing the same

A technology of thin-film solar cells and battery modules, applied in the direction of sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of large loss of space, increase of product weight, high automation costs, etc., to reduce weight and process time , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

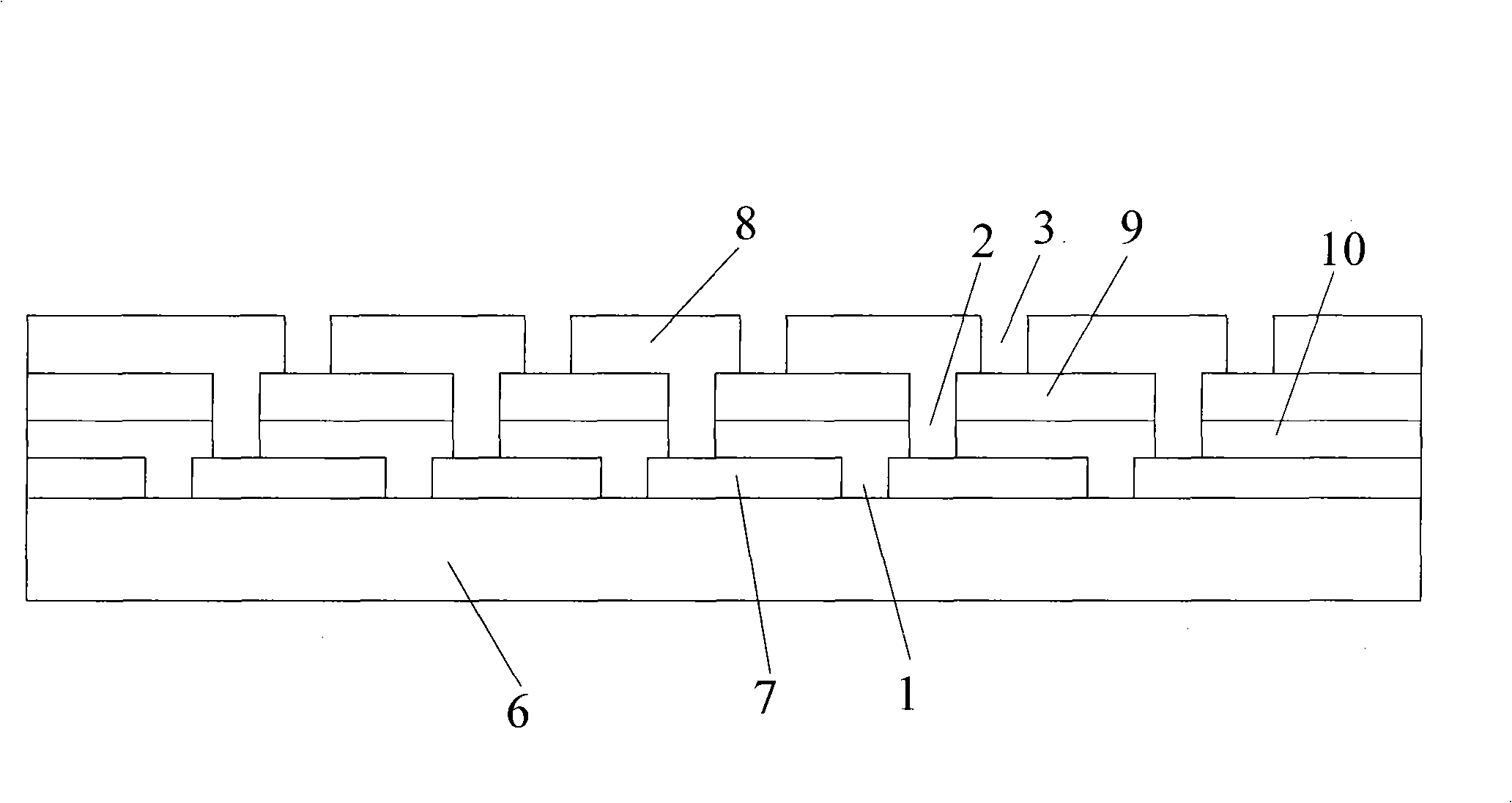

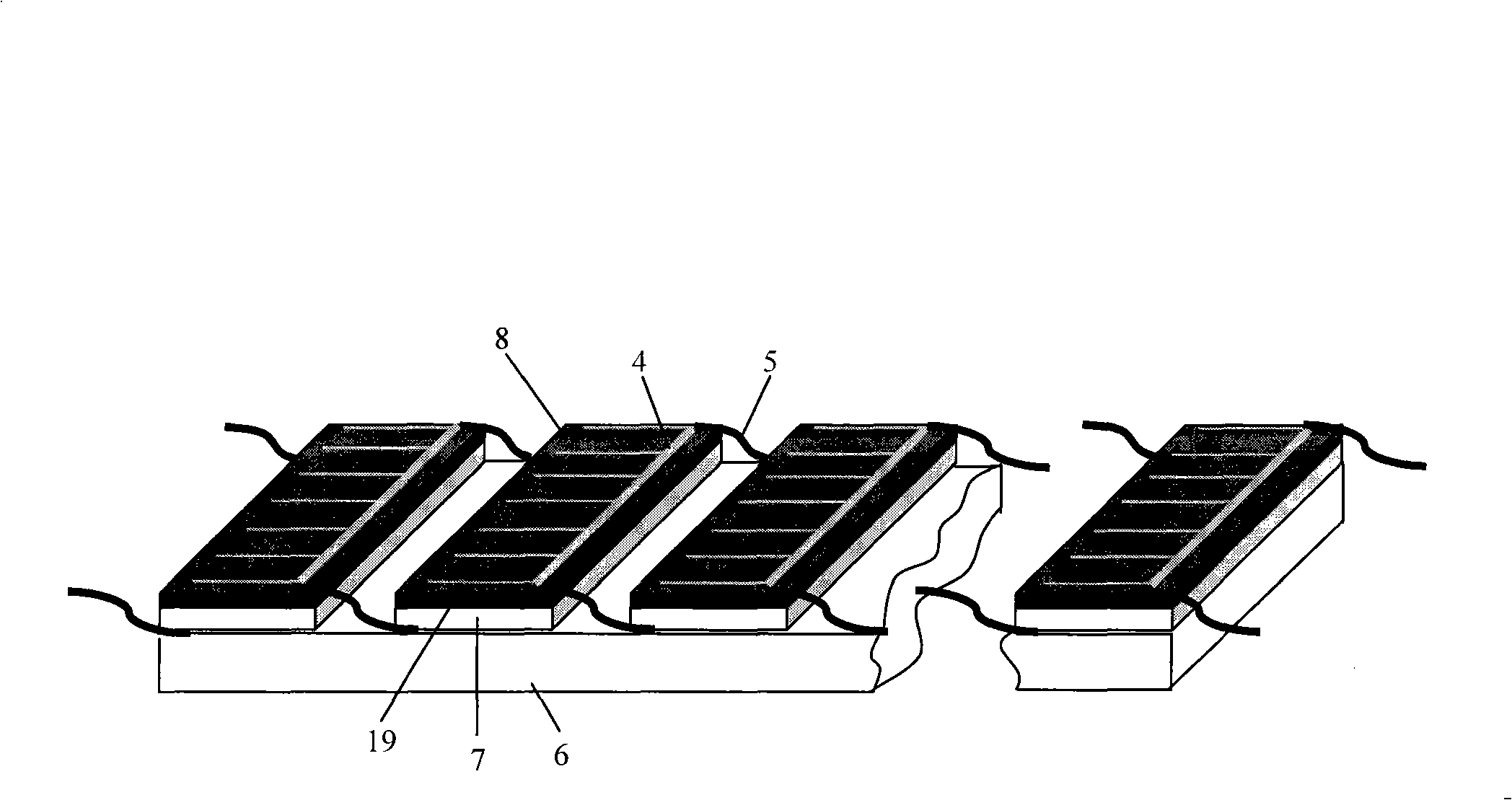

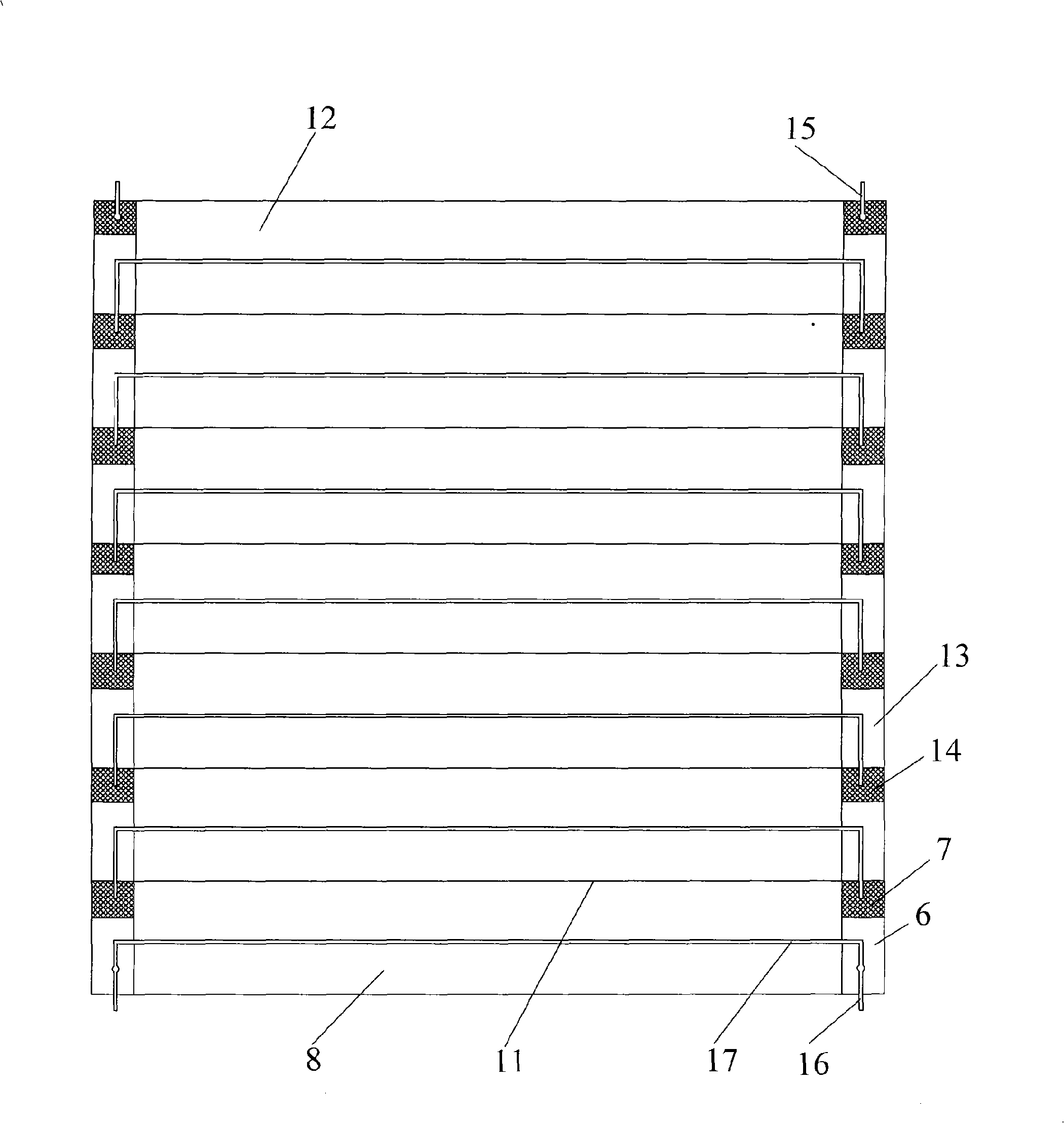

[0067] Such as Figure 3 to Figure 5 As shown, a thin-film solar cell module includes a substrate 6, a backlight conductive film 7 on the substrate 6, a power generation layer 19 on the backlight conductive film 7, and a transparent photoconductive film 8 on the power generation layer 19, and light 21 Irradiate downward from the direction of the photoconductive film 8, wherein the substrate 6 can be a rigid substrate such as a flexible substrate or glass, and the battery module is composed of several cut-off photoconductive film 8, power generation layer 19 and backlight conductive film 7. The fourth tangent groove 11 is divided into a plurality of module units 12, the substrate 6 extends outward in the direction of both ends of the module unit 12 with extensions 13, and the backlight conductive film 7 extends outwards to partially cover the extensions. 13, each module unit 12 is provided with an extraction electrode 17 on the photoconductive film 8, and the two ends of the ex...

specific Embodiment 2

[0085] Figure 9 and Figure 10 As shown, a thin-film solar cell module includes an extraction electrode 17 arranged on a transparent substrate 6, a photoconductive film 8 and a photoconductive film 8 covering the substrate 6 with the extraction electrode 17 sandwiched between the two. The power generation layer 19 on the power generation layer 19 and the backlight conductive film 7 on the power generation layer 19, such as Image 6 As shown, the light 21 is irradiated from the direction of the substrate 6, and the substrate 6 is a transparent substrate at this time. The battery module is divided into several module units 12 by a plurality of fourth tangent grooves 11 cut toward the photoconductive film 8, the power generation layer 19, and the backlight conductive film 7. The protruding part 13, the backlight conductive film 7 extends outwards with a protruding part 14 covering part of the protruding part 13, and the two ends of the lead-out electrode 17 are sandwiched betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com