Through type silver and copper composite ingot and making method for strips

A composite strip, through-type technology, used in metal rolling, metal rolling, manufacturing tools, etc., can solve the problem that the width uniformity of hot-rolled composite strips is difficult to control, the silver-copper interface cannot be fully extruded, and the bonding strength is not enough. Ideal and other problems, to achieve the effect of easy splicing, optimization of subsequent processing technology, and shortening of production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a method for preparing a through-type silver-copper composite ingot, and further provides a method for preparing a strip based on the prepared silver-copper composite ingot. Specifically include the following steps:

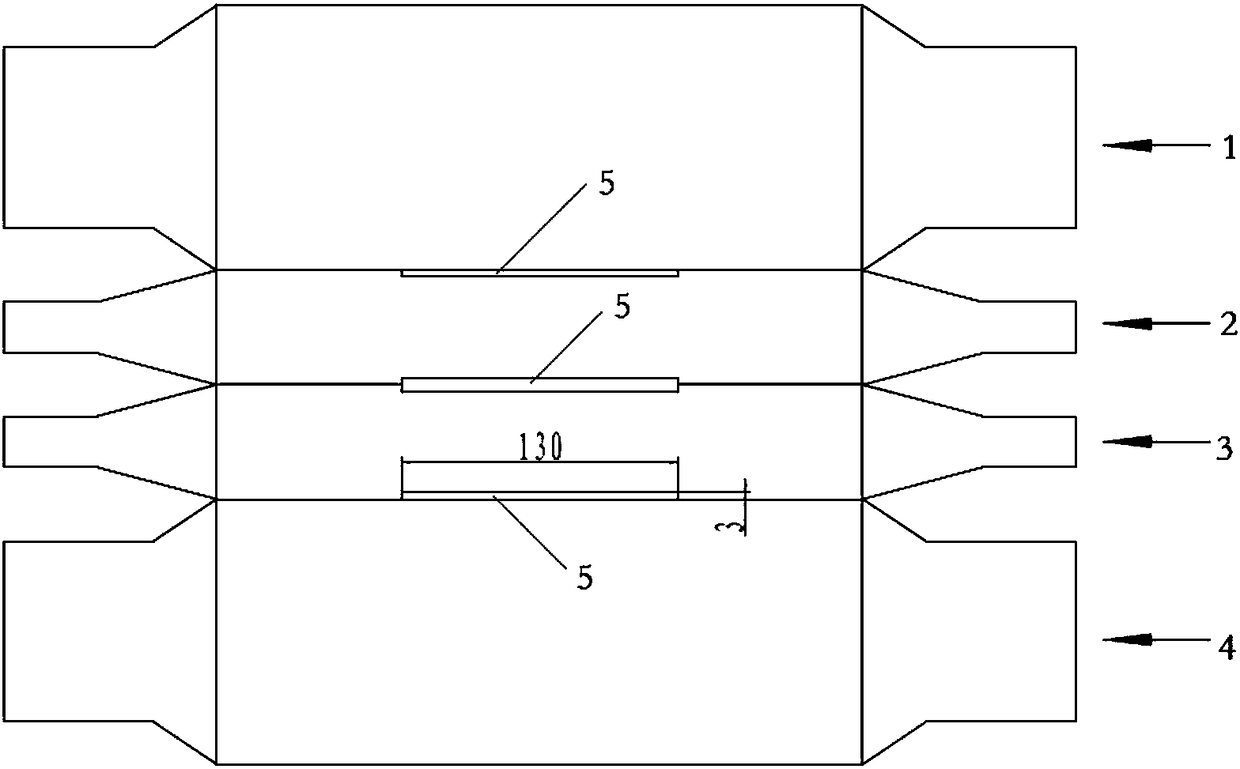

[0052] (1) The composite ingot composed of silver-copper dissimilar metals is spliced by a through-type method

[0053] After the copper bars, silver bars and copper frames are prepared, half of the copper bars, silver bars and copper frames are degreased and surface polished, and the other half of the copper bars are not subjected to surface treatment, and then the two treatment methods are different The raw materials are made into composite blanks, that is, through-type silver-copper composite ingots.

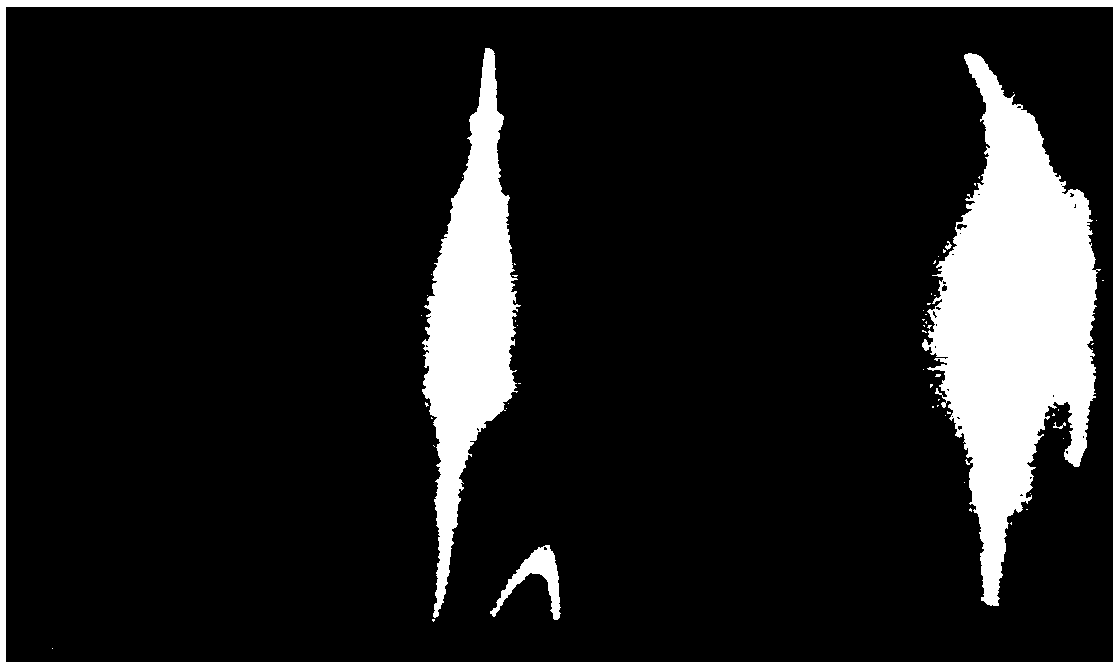

[0054] (2) Using the four-roller group solid-phase composite rolling mill to carry out deformation to the above-mentioned composite ingot is 70% cold composite treatment (rolling) to form a penetrating silver-copper side compos...

Embodiment 2

[0062] This embodiment provides a method for preparing a through-type silver-copper composite ingot, and further provides a method for preparing a strip based on the prepared silver-copper composite ingot. Specifically include the following steps:

[0063] (1) The composite ingot composed of silver-copper dissimilar metals is spliced by a through-type method

[0064] After the copper bar, silver bar and copper frame are prepared, the corresponding copper bar, silver bar and copper frame are softened and annealed at an annealing temperature of 600°C, the protective gas is hydrogen (the pressure in the furnace is greater than the atmospheric pressure), and the gas flow is 0.4~ 0.6m 3 / h, the annealing time is 2 hours, and then degreasing and surface grinding treatment, and then two silver plates and a copper plate are arranged and fastened in a rectangular copper frame to form a composite blank, that is, through-type silver-copper composite Ingots.

[0065] (2) using a four...

Embodiment 3

[0073] This embodiment provides a method for preparing a through-type silver-copper composite ingot, and further provides a method for preparing a strip based on the prepared silver-copper composite ingot. Specifically include the following steps:

[0074] (1) The composite ingot composed of silver-copper dissimilar metals is spliced by a through-type method

[0075] After the copper bars, silver bars and copper frames are prepared, the corresponding copper bars, silver bars and copper frames are softened and annealed, the annealing temperature is 550°C, the protective gas is hydrogen (the pressure in the furnace is greater than the atmospheric pressure), and the gas flow is 0.4~ 0.6m 3 / h, the annealing time is 3 hours, and then degreasing and surface grinding treatment, and then two silver plates and a copper plate are arranged and fastened in a rectangular copper frame to form a composite blank, that is, through-type silver-copper composite Ingots.

[0076] (2) using a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com