Abrasive water jet-electrolysis composite pass making method and device for metal part with thermal barrier coating

A technology of abrasive water jet and metal parts, which is applied in the field of abrasive water jet-electrolytic composite hole making, can solve the problems of complex process, difficult quality control, high processing cost, etc., and achieve the effect of simple process and easy guarantee of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

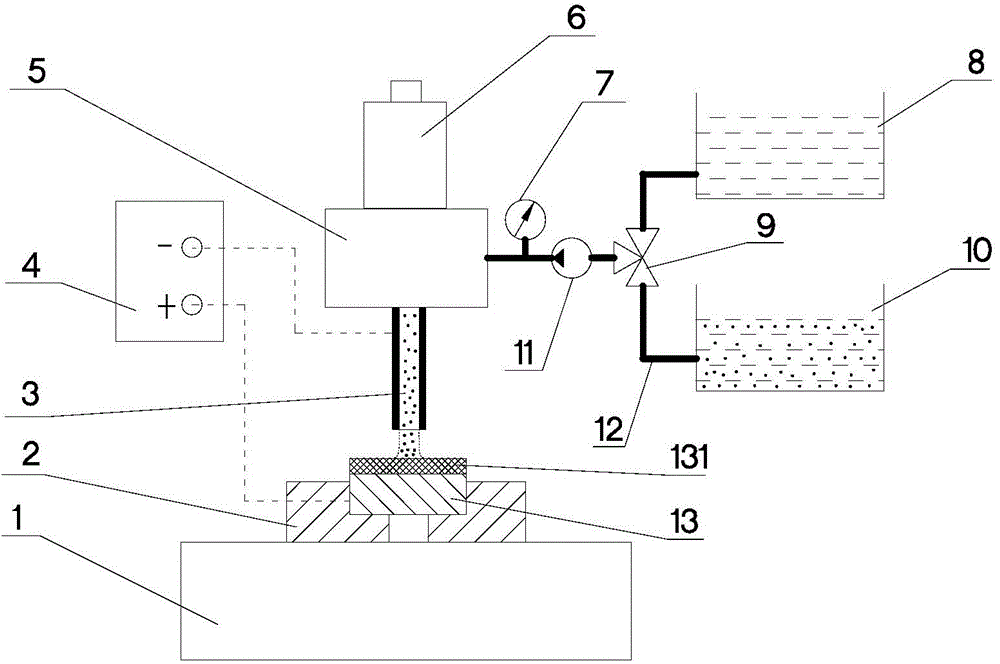

[0024] The abrasive water jet-electrolytic composite hole-making method of metal parts with thermal barrier coating of the present invention comprises the following steps:

[0025] (1) power off 4;

[0026] (2) Installation and positioning of the workpiece 13: the workpiece 13 is installed and positioned on the workbench 1 through the fixture 2;

[0027] (3) Installation and positioning of the tool electrode 3: the tool electrode 3 is installed and positioned on the liquid inlet joint 5, and the positions of the liquid inlet joint 5 and the tool electrode 3 are adjusted through the servo feed device 6 (the distance between the end face of the tool electrode 3 and the surface of the workpiece 13 10-20mm);

[0028] (4) Machining the pass pattern of the thermal barrier coating by abrasive water jet: the solenoid valve 9 connects the abrasive working fluid tank 10, disconnects the electrolytic working fluid tank 8, starts the infusion pump 11, and the abrasive working fluid enter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com