Improved bidirectionally stressed foundation knot attached to lifting scaffold

A technology for attaching lifting and scaffolding, applied in the accessories of scaffolding, scaffolding supported by housing structure, housing structure support, etc., can solve the problems of high risk, affect safety, low construction efficiency, etc., and achieve excellent bending moment resistance and anti-bending Torque, improve overall safety performance, and improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

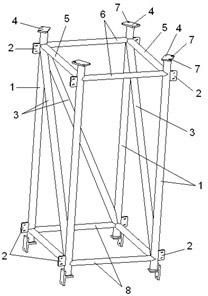

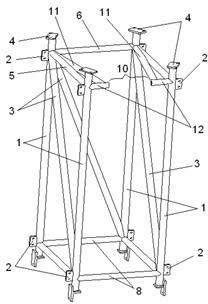

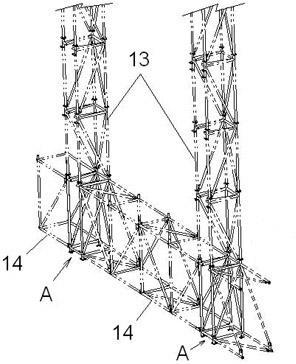

[0020] figure 1 What is shown is a structural form of the two-way force-bearing foundation section of the improved attached lifting scaffold of the present invention. Two sets of parallel horizontal rods (such as iron pipes, steel pipes, etc., the same below) 6, 8, two sets of parallel front and rear longitudinal rods 5 on the left and right, and two sets of parallel vertical rods 1 are fixed The connecting plates with holes on the rod-shaped members are fastened by bolts to form a stable integral rectangular hexahedron frame structure, in which at least one pair of non-adjacent end points in at least one plane formed by adjacent rod-shaped members are connected Diagonal strut 3 is arranged. As shown in the figure, a diagonal strut 3 is respectively arranged in three different planes of the frame structure. At the upper and lower ends of each vertical rod-like member 1, there are respectively disc-type connection plate structures 4 with connection holes 7, wherein the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com