The hydraulic connection structure connecting the crosshead body and the piston rod

A technology of crosshead body and connection structure, which is applied in the direction of crosshead, liquid displacement machinery, variable displacement pump components, etc. It can solve the problems of one side deviation of the drill bit, troublesome repair of parts, replacement of new tooling, etc., and achieve saving Materials, simple processing, and the effect of ensuring processing quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

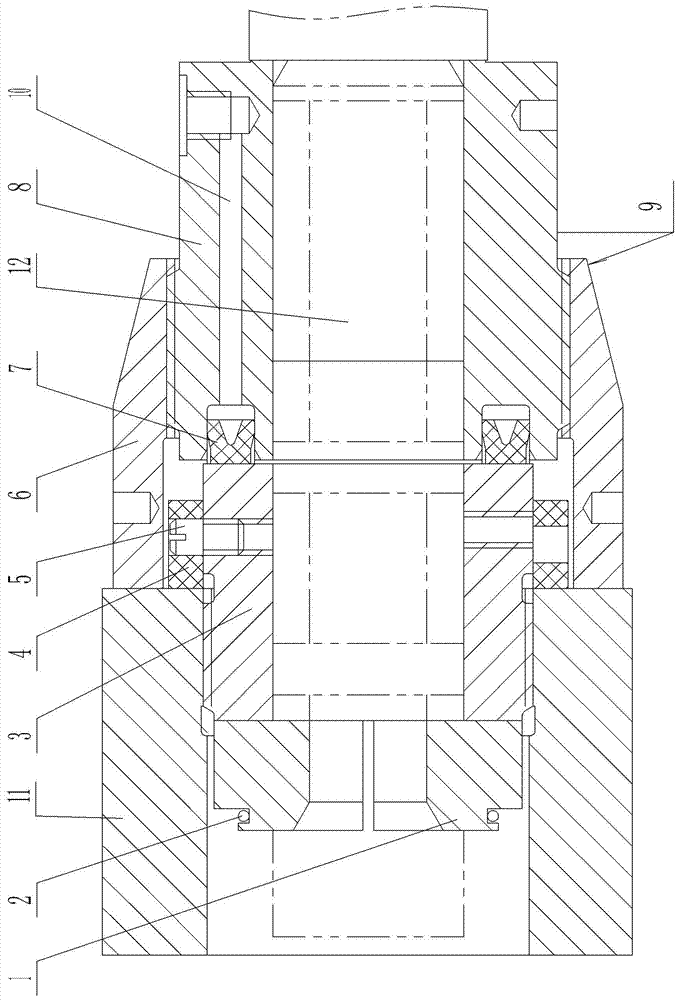

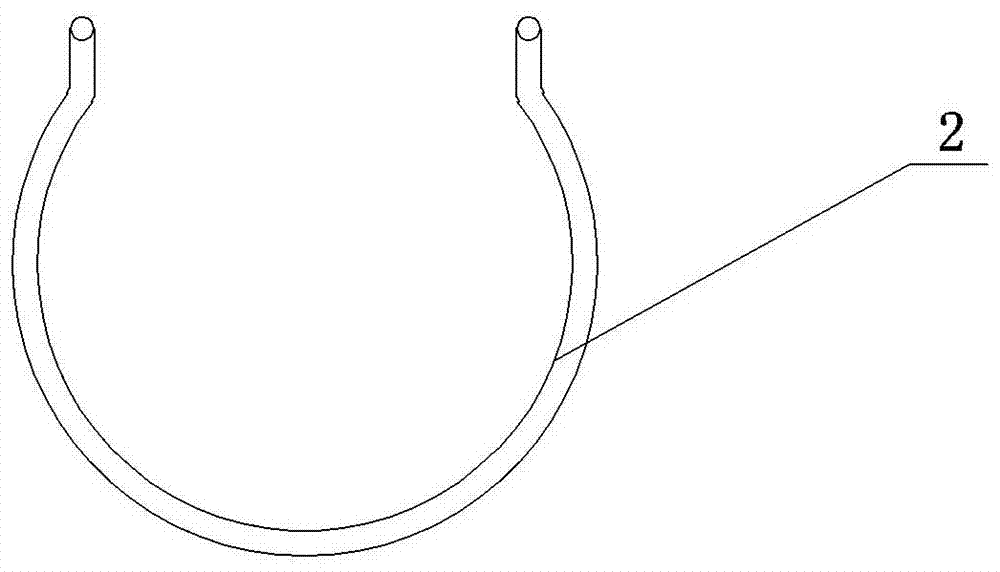

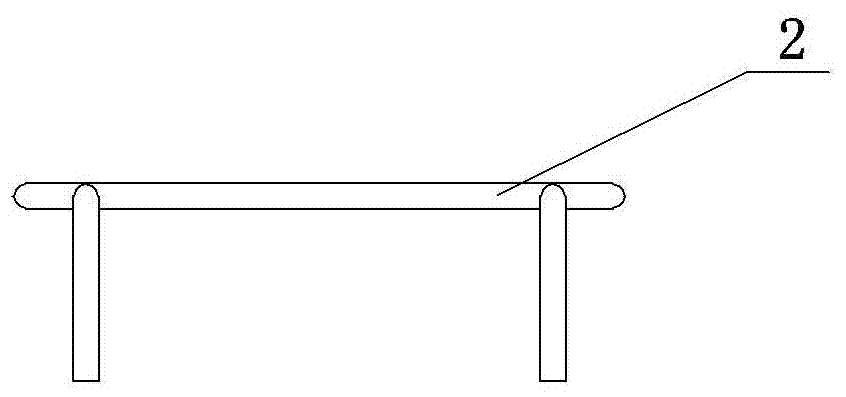

[0043] As shown in the figure, the present invention includes a crosshead body and a piston rod. One end of the piston rod is placed in the crosshead body, and a thrust ring is arranged at the rear end of the piston rod placed in the crosshead body. A screw-in ring is provided, the front part of the outer ring of the screw-in ring is threadedly connected with the inner wall of the crosshead, the rear part of the screw-in ring is placed outside the crosshead body, and a pressure body is arranged on the periphery of the piston rod at the rear end of the screw-in ring, and the outer wall of the front part of the pressure body It is threadedly connected with the rear part of the fastening nut, and the front end of the fastening nut is connected with the end surface of the crosshead body; the rear end of the pressure body is provided with a vertical pressing hole, the lower part of the vertical pressing hole is connected with one end of the horizontal pressing hole, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com