Method for processing sector gear

A technology of sector gears and processing methods, applied in metal processing equipment, gear tooth manufacturing devices, belts/chains/gears, etc., can solve problems such as low processing efficiency and large deformation, and achieve the effect of ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

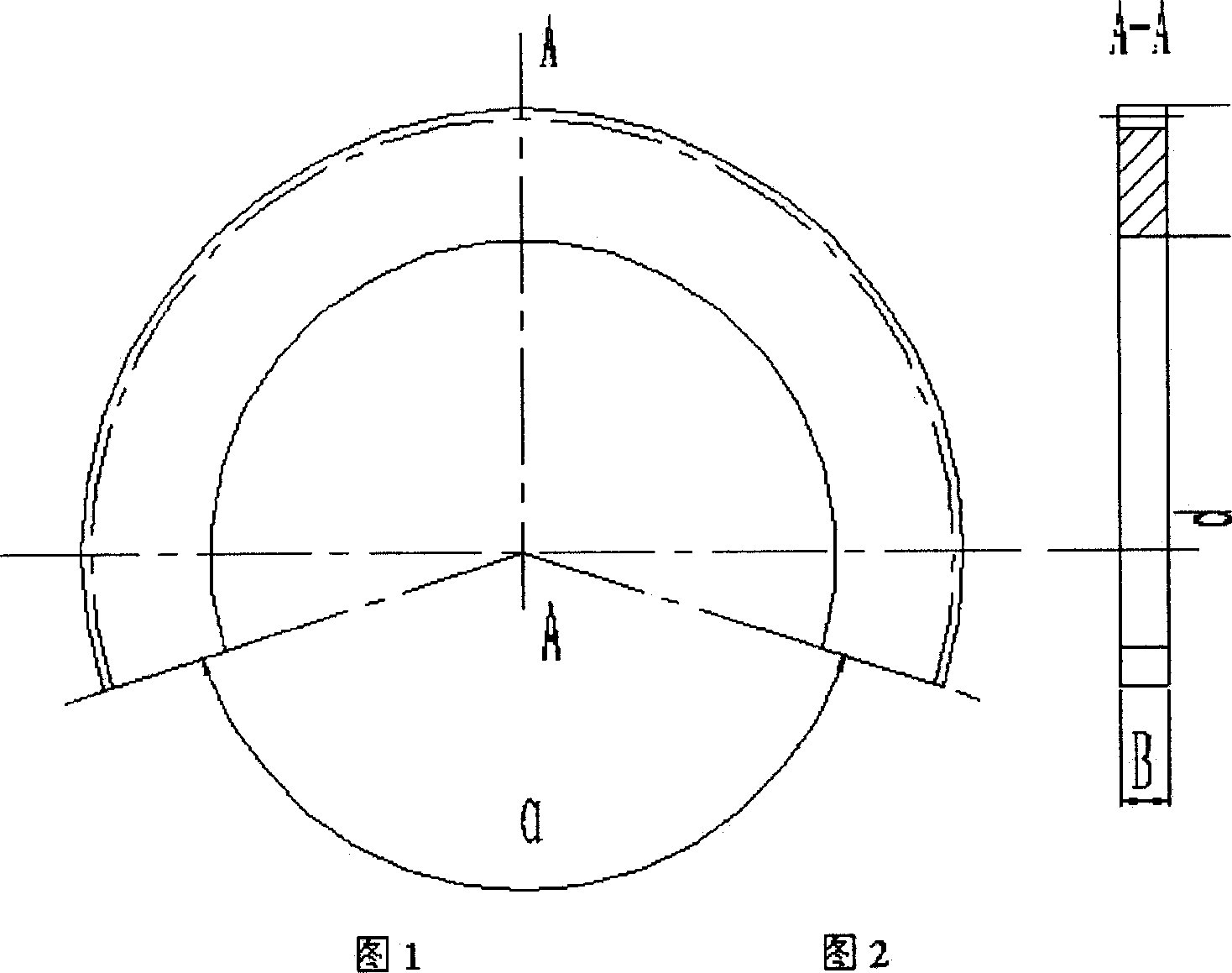

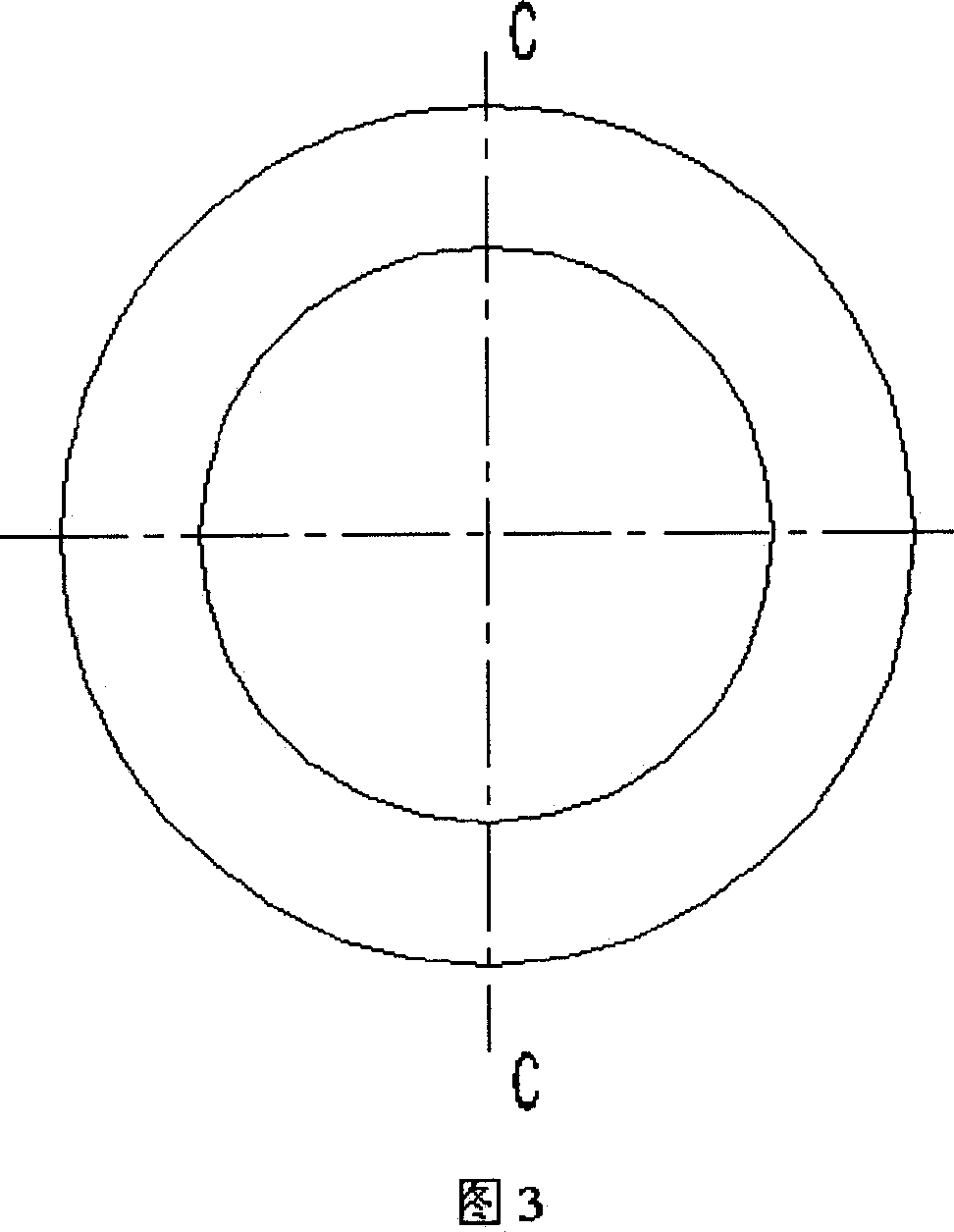

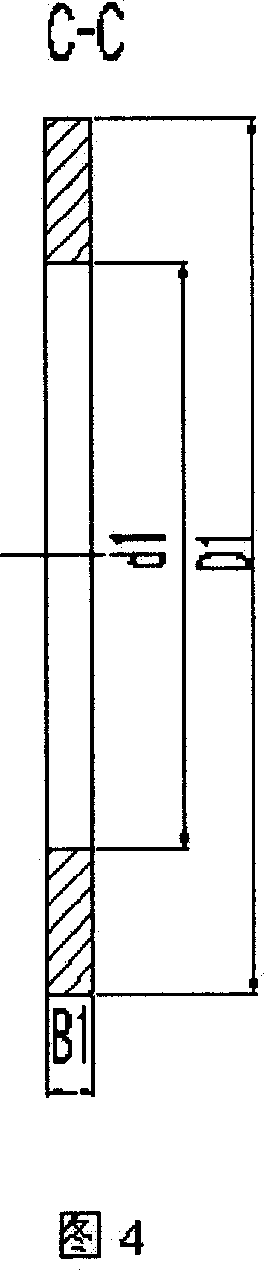

[0028] Embodiment of the present invention: the sector angle of the sector gear to be processed is: 360o-α, the blank size is: outer circle diameter D, inner hole diameter d, width B, and the machining process includes the following steps:

[0029] First, the rough machining of the tooth blank

[0030] The tooth blank is processed into the shape required by the drawing, and the inner hole and the outer circle are left with sufficient correction allowances according to the shape and structure of the sector gear and the size of the possible deformation.

[0031] Second, make the tooling board

[0032] Make the tooling plate according to the structural shape and size of the sector gear when it is complete, and the outer diameter of the tooling plate is D 1 , inner hole diameter d 1 Respectively consistent with the outer diameter D and inner hole diameter d in the rough machining of the sector gear blank, the width B of the tooling plate 1 Greater than or equal to the width B i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com