Dense girt strip hollow building roof composition board fixture mould

A hollow floor and composite board technology, used in molds, manufacturing tools, ceramic molding machines, etc., can solve problems such as easy deformation, unusability, and uneven concrete surface, achieve good occlusion and bonding, speed up production efficiency, Easy to process quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

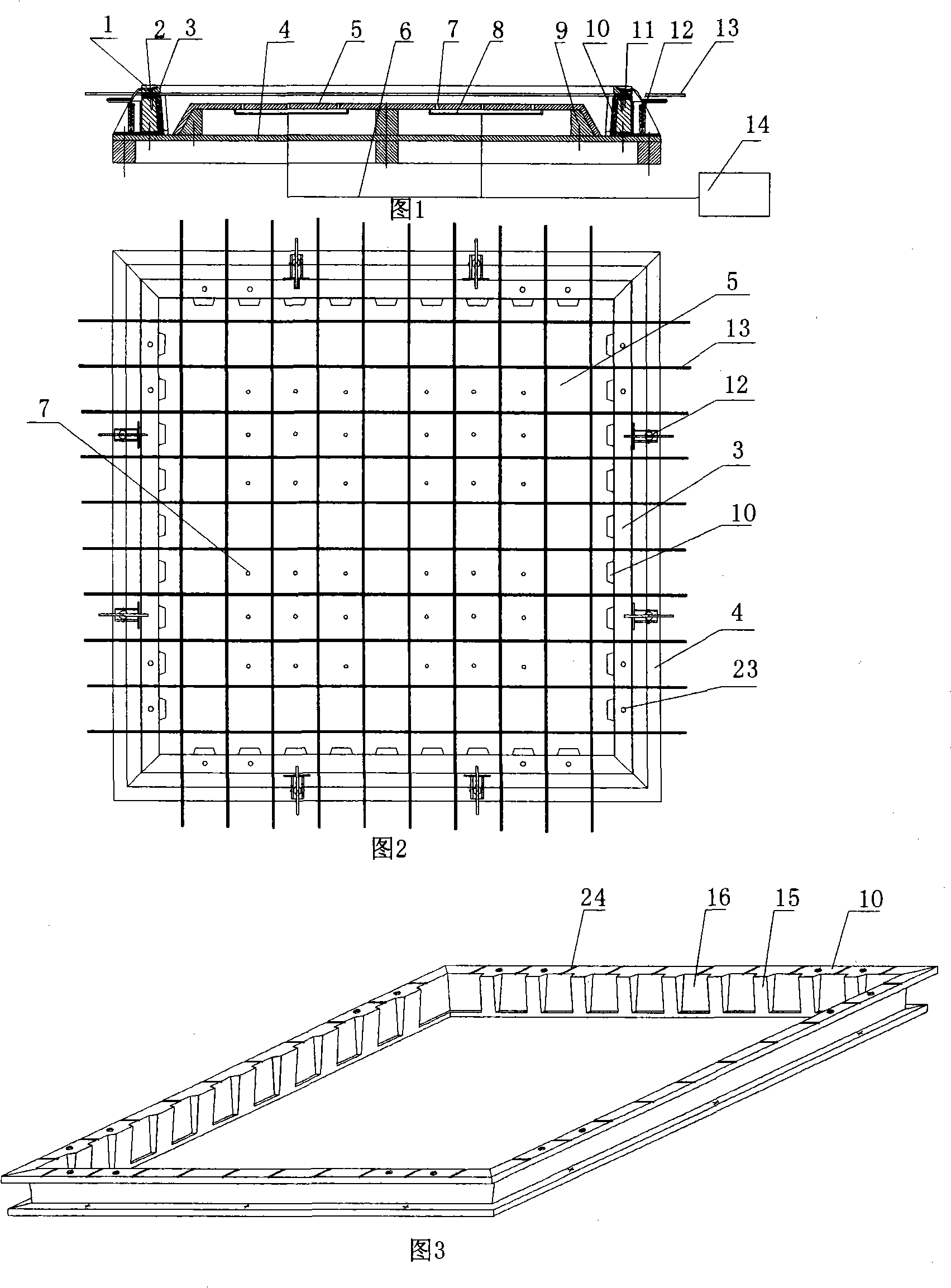

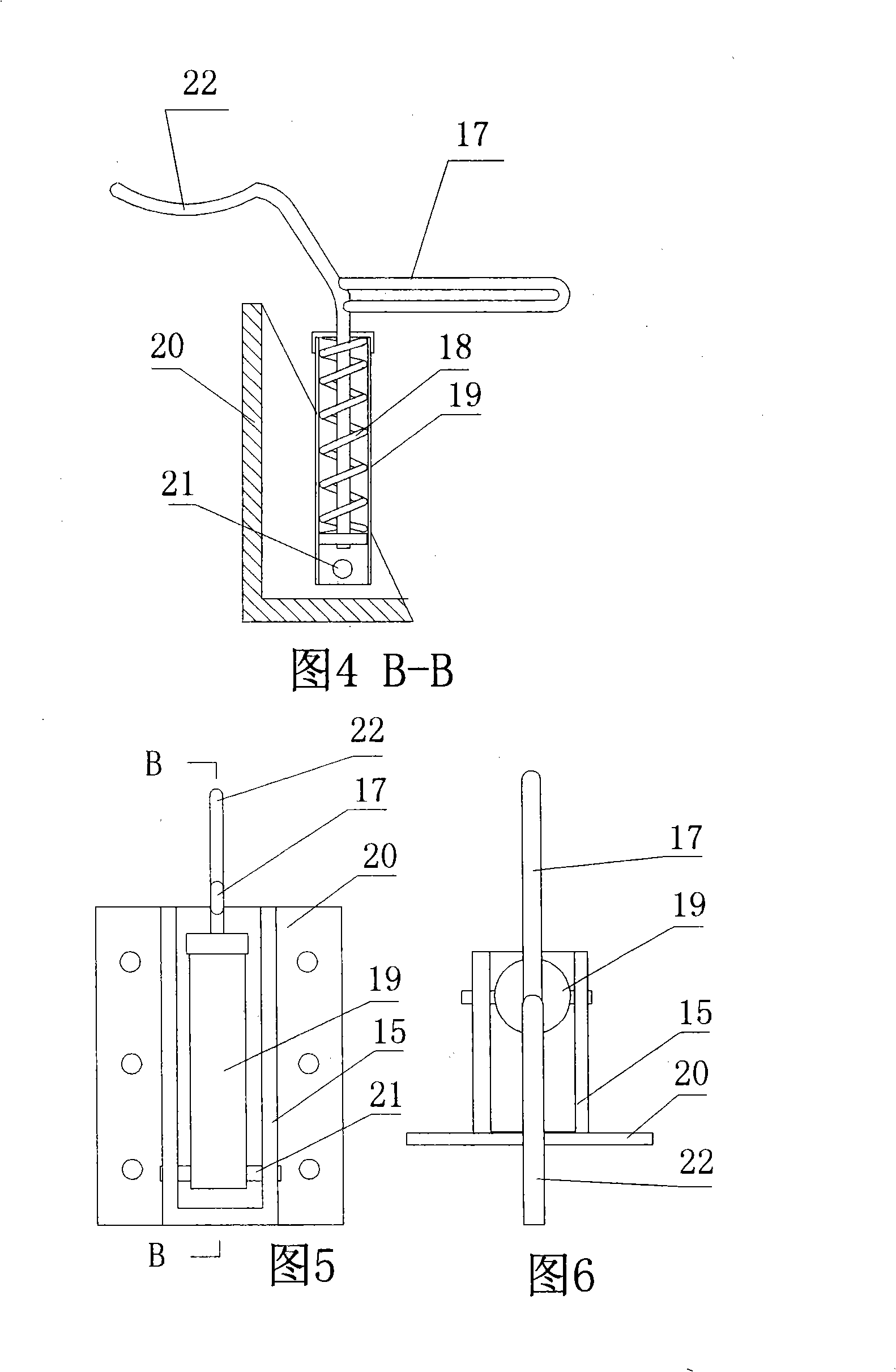

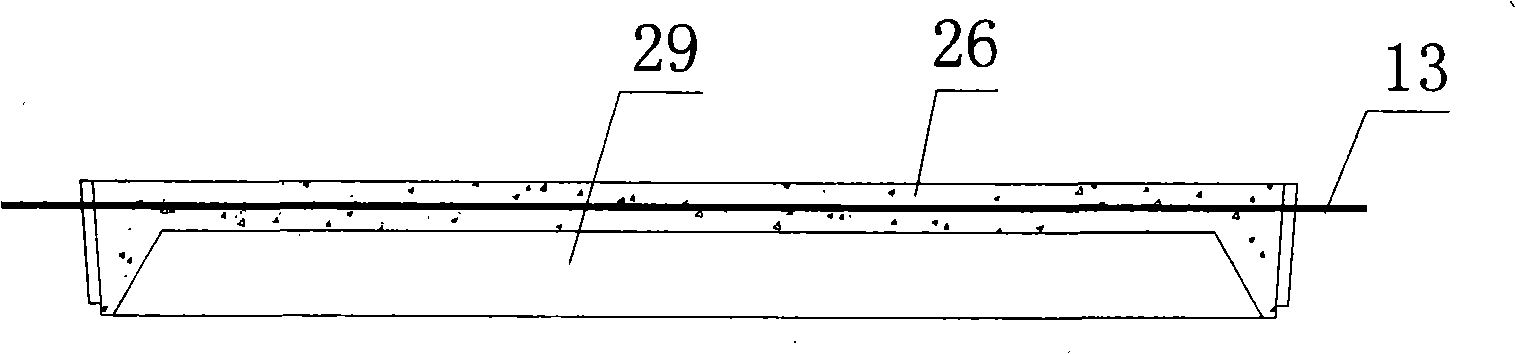

[0025] As shown in accompanying drawing 1, the method of using the tooling mold of the present invention is as follows, arrange the beard tendon in the semicircular groove on the upper part of the outer mold in a net shape, then press it with beard tendon beading, and finally use beard tendon beading Press it, the bead hook of the beading device is embedded in the groove of the upper hook of the beard tendon beard, pour concrete into the space between the inner mold and the outer mold, use a vibrator to vibrate and exhaust the concrete to make the concrete compact, and use a scraper along the beard The upper surface of the rib bead is scraped flat, and finally the prefabricated prefabricated composite slab of densely ribbed beam and hollow floor together with the beard beard bead are fastened on the flat ground with sand, and the inner mold is inflated with the air pump, and it is released under the action of air pressure. The mold can be removed, and the next pouring of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com