Steel reinforced concrete structure formwork sleeve threaded rod pulling construction method

A technology of concrete structure and construction method, which is applied to the connection parts of formwork/formwork/work frame, building structure, and on-site preparation of building components, which can solve the problems of difficulty in supporting and reinforcing the formwork system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

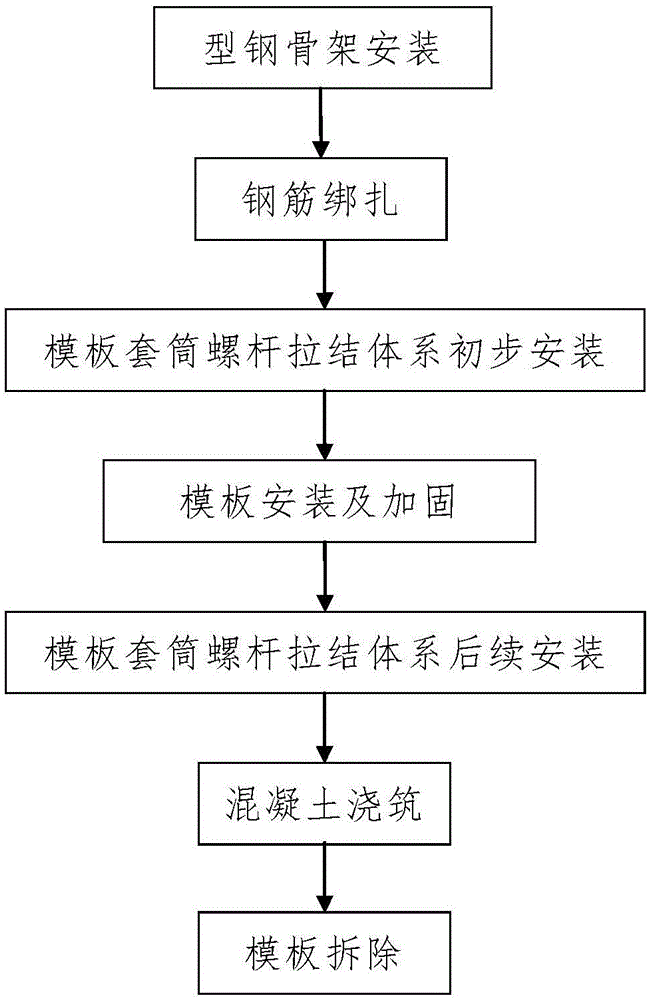

[0078] Such as figure 1 The shown construction method of a steel-concrete structure formwork sleeve screw tie, comprises the following steps:

[0079] Step 1. Installing the steel frame: install the steel frame 1 in the steel concrete structure to be constructed;

[0080] Step 2, steel bar binding: on the outside of the steel frame 1 installed in step 1, the steel cage in the steel concrete structure is bound;

[0081] Step 3. Preliminary installation of the formwork sleeve screw tie system: perform preliminary installation on the pre-processed formwork sleeve screw tie system;

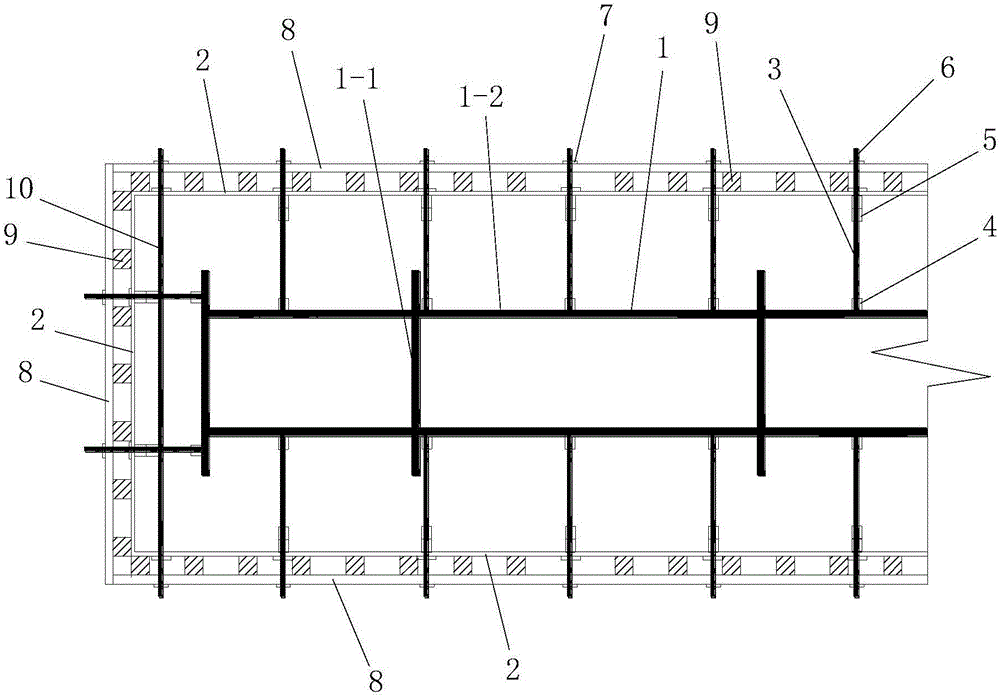

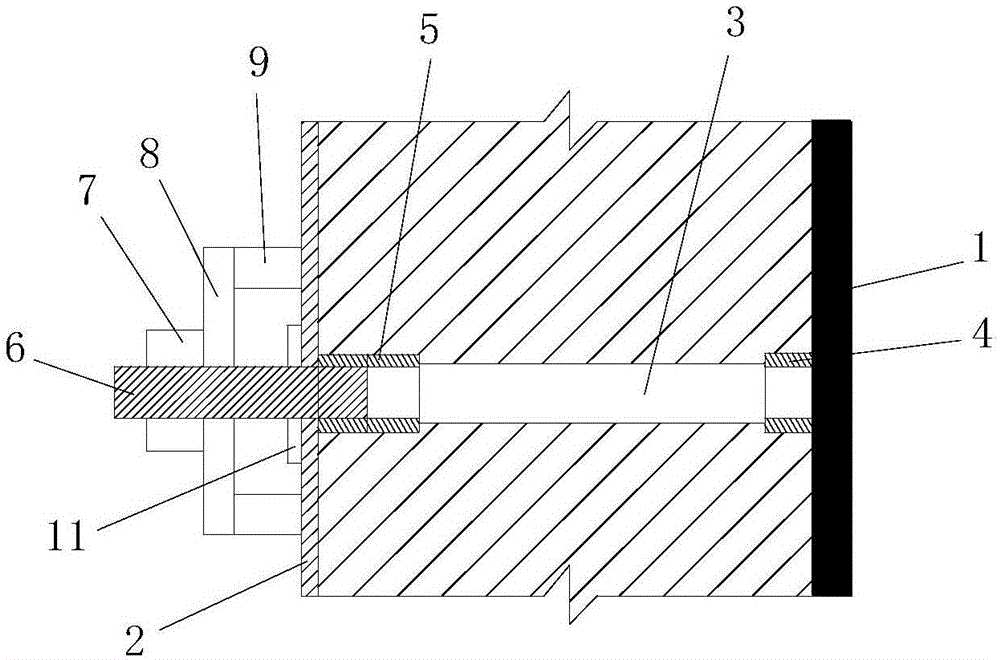

[0082] Such as figure 2 As shown, the template sleeve screw tie system includes a plurality of horizontal sleeve screw tie devices arranged on the same level from front to back and a plurality of longitudinal sleeve screw tie devices arranged on the same level from left to right Knotting device, the structure of multiple said horizontal sleeve screw pulling devices is the same and they are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com