Surfacing corrosion resistant alloy lined composite tee in transition circular arc and manufacturing method thereof

A technology of corrosion-resistant alloys and transitional arcs, which is applied in the direction of branch pipelines, pipes, pipes/pipe joints/fittings, etc., which can solve the problem of restricting the application range of bimetallic composite pipes, difficult to apply bimetallic composite pipe connections, and poor corrosion resistance and other problems, to achieve the effects of easy guarantee of processing quality, improvement of processing efficiency, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

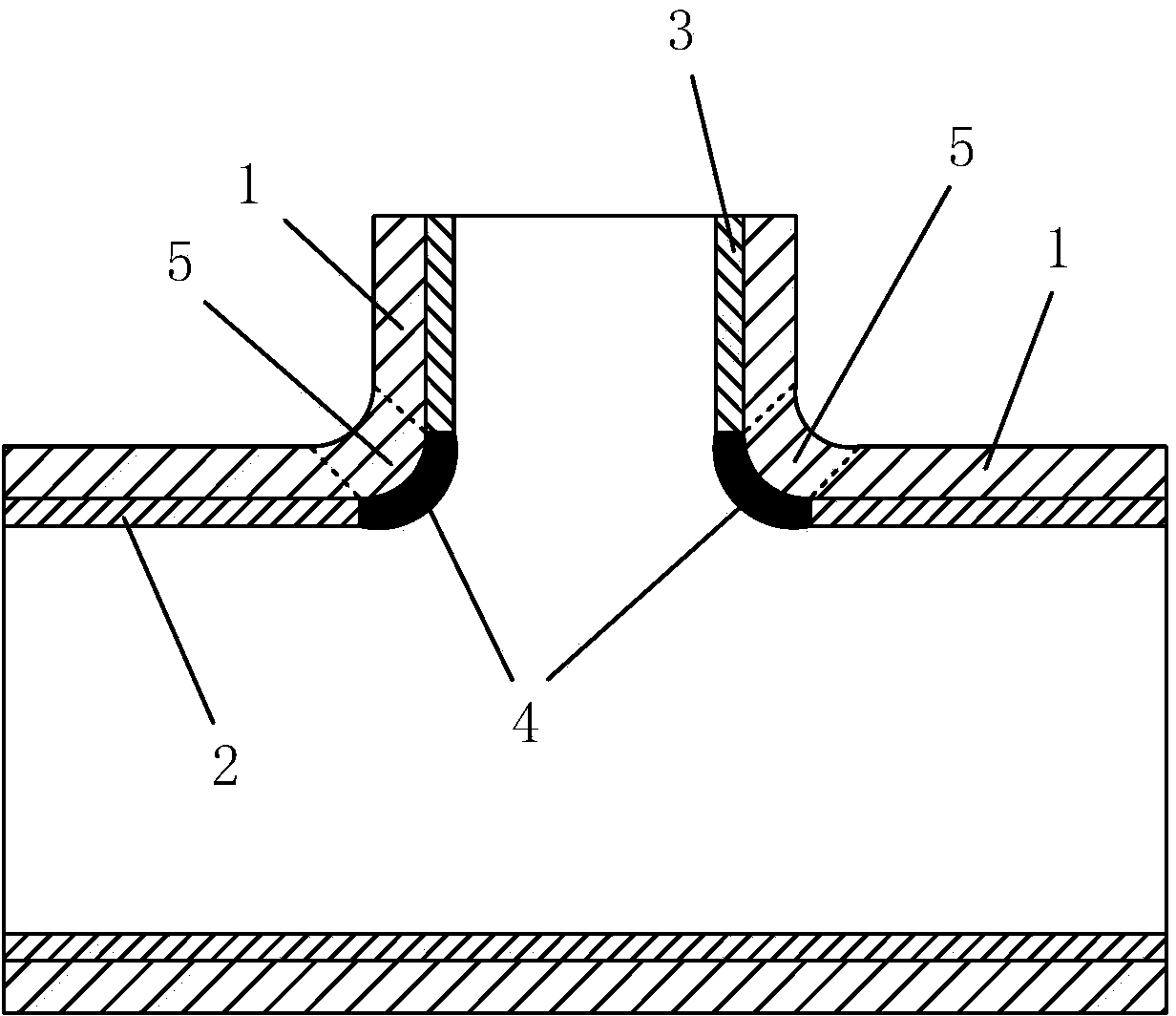

[0030] Such as figure 1 A corrosion-resistant alloy-lined composite tee with surfacing welding in a transitional arc shown includes a tee pipe 1, and the tee pipe 1 is composed of a main pipe and a branch pipe arranged on the main pipe. The insides of the branch pipes communicate with each other. A liner pipe 1 2 is coaxially installed in the main pipe, and a liner pipe 2 3 is coaxially installed in the branch pipe. The wall thickness of the liner pipe 1 2 and the liner pipe 2 3 is the same. A mounting hole is opened on the side wall of the liner-2. The second lining pipe 3 is loaded into the branch pipe from the outside to the inside and its inner end is installed on the installation hole, and the inner end of the second lining pipe 3 and the installation hole are welded connection, the cross-sectional shape of the surfacing layer 4 formed between the inner end of the lining pipe 2 3 and the installation hole is arc-shaped, and the layer thickness of the surfacing layer 4 i...

Embodiment 2

[0056] In this embodiment, the difference between the anti-corrosion alloy lined composite tee manufactured by overlay welding in the transitional arc and embodiment 1 is that the outer diameter of the main pipe is Φ1220mm and the wall thickness is 50mm, and the overlay welding The layer thickness of layer 4 is 4mm, and the corrosion-resistant alloy is a nickel-based alloy; the material of the tee pipe 1 is alloy steel; The assembly gap between the branch pipes is 8mm; the length of the inner liner pipe 2 is 2100mm; the length of the main pipe is 1780mm.

[0057] In this embodiment, the dimensions of the remaining parts of the corrosion-resistant alloy-lined composite tee manufactured by surfacing in the transitional arc are the same as those in Embodiment 1.

[0058] In this embodiment, the manufacturing method of the anti-corrosion alloy lined composite tee used for surfacing welding in the transitional arc is different from that of Example 1 in that: when surfacing welding ...

Embodiment 3

[0061] In this embodiment, the difference between the corrosion-resistant alloy-lined composite tee manufactured by overlay welding in the transitional arc and embodiment 1 is that the outer diameter of the main pipe is Φ660mm and its wall thickness is 24mm, and the overlay welding The layer thickness of layer 4 is 3mm, and the corrosion-resistant alloy is copper alloy; the material of the tee pipe 1 is carbon steel; The assembly gaps between them are all 4mm; the length of the liner-2 is 1090mm; the length of the main pipe is 990mm.

[0062] In this embodiment, the dimensions of the remaining parts of the corrosion-resistant alloy-lined composite tee manufactured by surfacing in the transitional arc are the same as those in Embodiment 1.

[0063] In this embodiment, the manufacturing method of the anti-corrosion alloy lined composite tee used for surfacing welding in the transitional arc is different from that of Example 1 in that: when surfacing welding is carried out in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com