Manufacturing method for forging die

A manufacturing method and technology of forging dies, applied in the direction of manufacturing tools, forging/pressing/hammering machinery, forging/pressing/hammer devices, etc., can solve problems such as difficulty in product quality assurance and high manufacturing costs, and reduce manufacturing costs. The mold processing cycle is shortened and the processing quality is easily guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

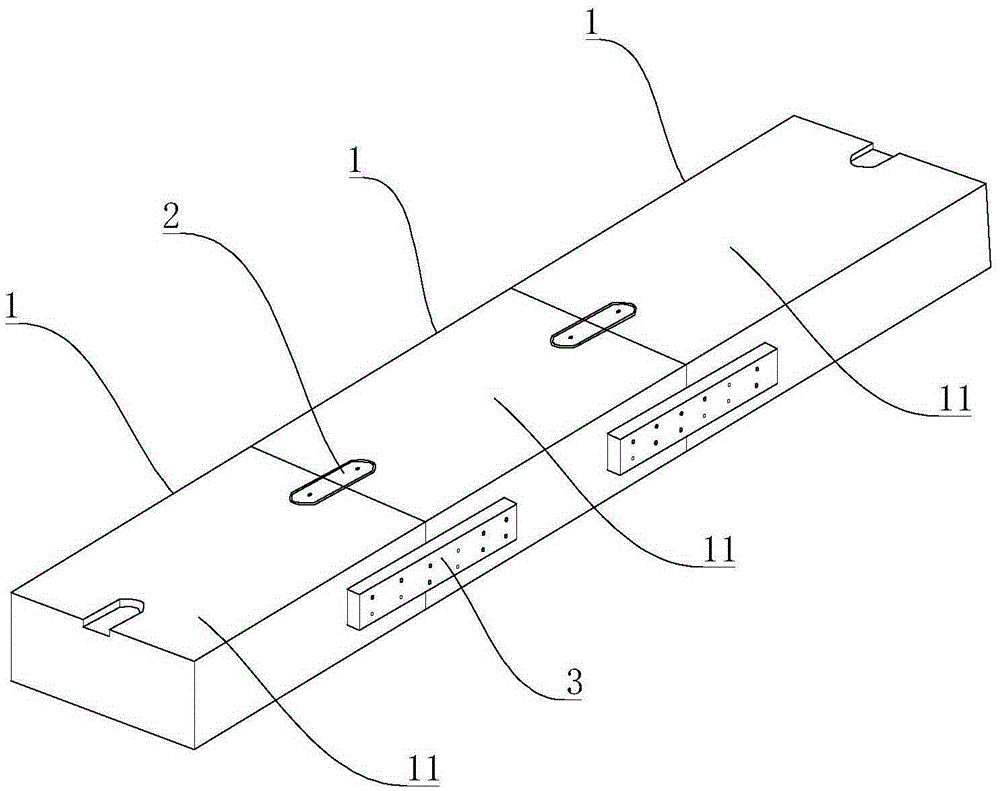

[0019] The present invention will be further explained below in conjunction with the drawings and embodiments:

[0020] The forging die manufacturing method includes the following steps in sequence:

[0021] A. Design the overall mold and calculate the load and residual stress distribution in three directions in space when the mold is working;

[0022] B. According to the residual stress distribution obtained in step A, design the splicing seam position of the sub-mold. The splicing seam position should avoid the residual stress concentration area, and all sub-molds are spliced to form the same mold cavity as the overall mold;

[0023] C. According to the loads in the three directions of space obtained in step A, design the material, shape and specifications of the connecting parts for the bottom and side surfaces of the sub-mold at the splicing position, and it is required that the connecting parts are used for the sub-mold splicing to meet the overall requirements. The design stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com