Friction welding type kelly bar

A friction welding and kelly technology, which is used in drill pipes, earth-moving drilling, drilling pipes, etc., can solve the problems of uncontrollable welding accuracy and welding quality, long production cycle, and large material waste, saving raw materials and energy. , the effect of high production efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

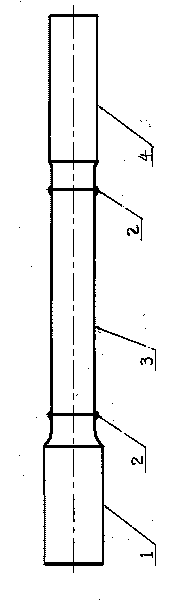

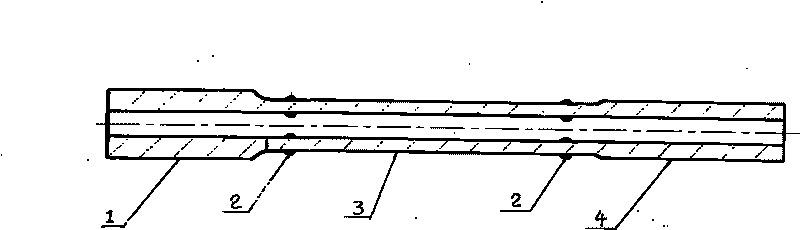

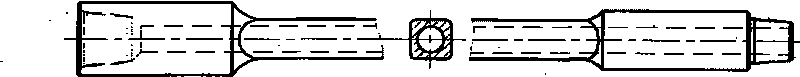

[0014] Refer to attached Figure 1-2 , Before welding, the first joint 1 or the second joint 4 to be welded is clamped on the rotating fixture of the friction welding machine, which is called a rotating workpiece. The pipe body 3 is clamped by the moving fixture of the friction welding machine, which is called a moving workpiece. During welding, the rotating workpiece starts to rotate at a high speed driven by the motor, and the moving workpiece gradually moves closer to the rotating workpiece under the action of the axial force. After the workpieces on both sides are contacted and pressed tightly, some asperities on the friction interface first bond and shear , and generate frictional heat. As the actual contact area increases, the friction torque increases rapidly, and the temperature at the friction interface rises accordingly, and the friction interface is gradually covered by a layer of high-temperature viscoplastic metal. At this time, the relative movement of the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com