Method for monitoring performance degradation state of stay cable anchor head based on fiber distributed measurement

A fiber optic distributed, cable-stayed anchor technology, applied in the direction of measuring force, measuring device, measuring the change force of the optical properties of the material when it is stressed, can solve the problems of real-time monitoring, damage, debonding, Defects and cracks, etc., to achieve the effect of continuous monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

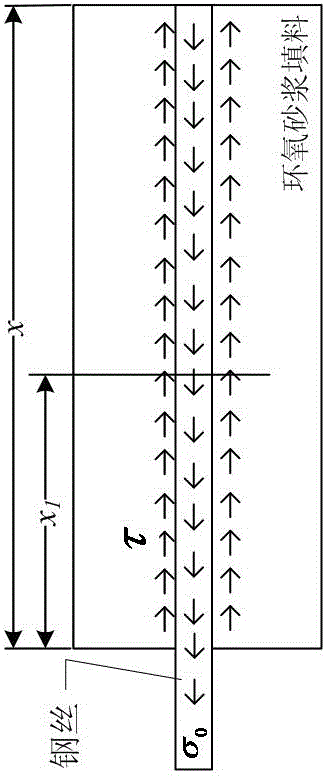

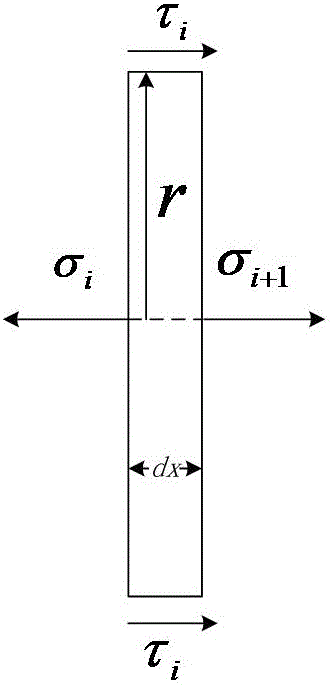

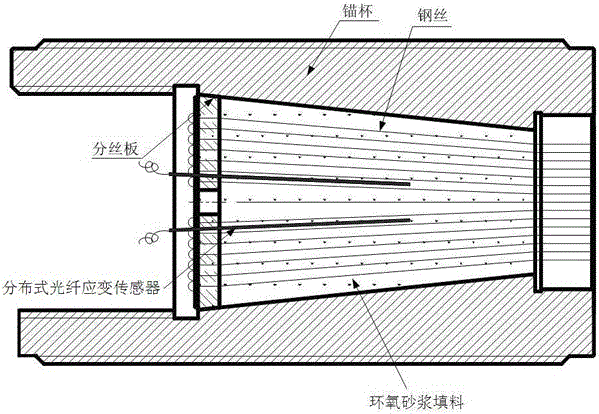

[0032] A cable-stayed cable anchor head performance degradation state monitoring method based on optical fiber distributed measurement. At the bottom of the cup, there are multiple reserved holes on the wire splitter plate. The inner end of the steel wire passes through the reserved holes on the wire splitter board and then the pier head is fixed. The multiple steel wires correspond to the reserved holes one by one. The area around the steel wire is filled with epoxy mortar filler; the innovation is that the method for monitoring the state of performance degradation of the stay cable anchor head includes:

[0033] 1) Multiple implantation holes are prefabricated on the solid part of the splitter board; during the anchor head production process, before pouring epoxy mortar filler, a thin strip of distributed optical fiber strain is implanted in each implantation hole Sensor, the axis of the distributed optical fiber strain sensor is parallel to the steel wire axis, the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com