Prestress member capable of being monitored, prestress loss monitoring method and manufacturing method

A technology of prestressing and prestressing tendons, which is applied in the direction of building structure, elastic testing, computer parts, etc., can solve the problems of long-term monitoring projects that are difficult to meet, affect the measurement accuracy of pressure sensors, and the deviation of anchorage and structure ends, etc. problems, to achieve the effect of preventing information from being modified or leaking sensitive information, increasing the level of automatic structural inspection, and improving the efficiency of structural maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

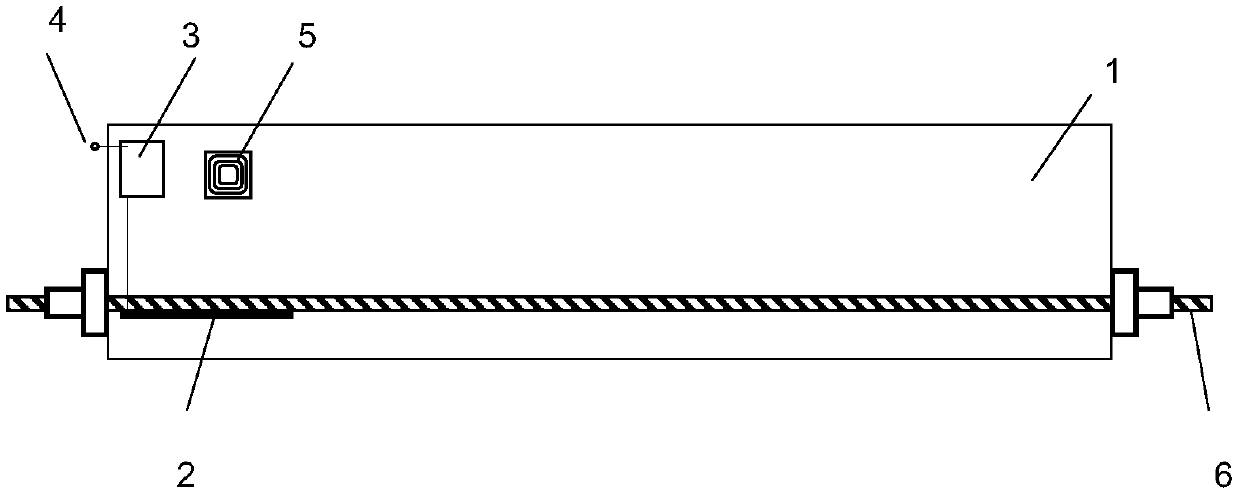

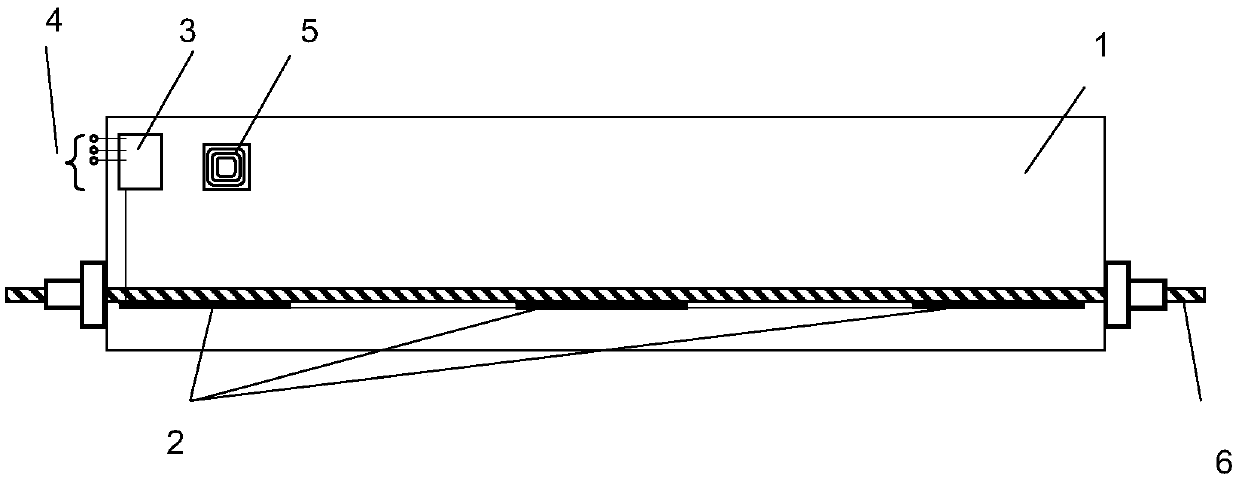

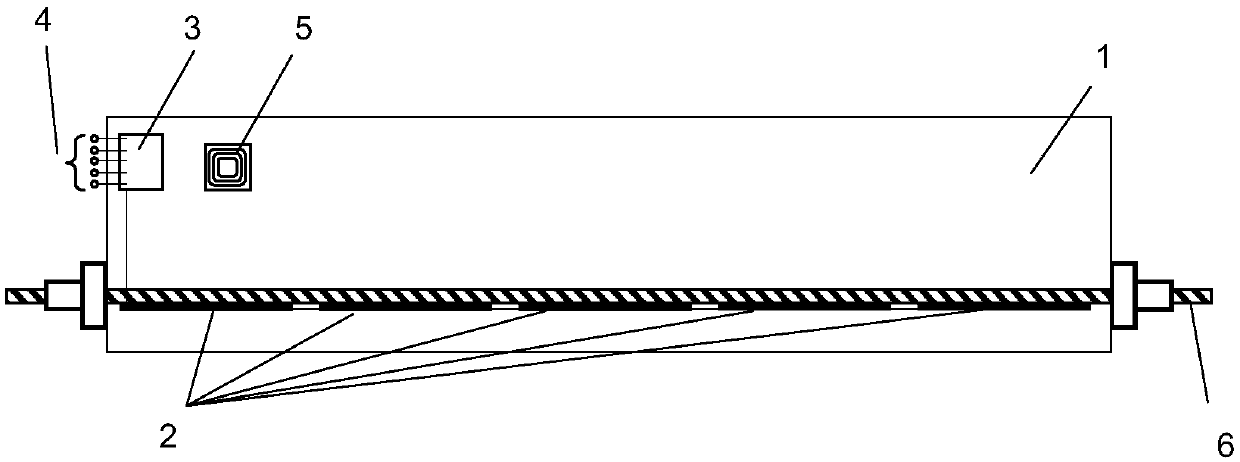

[0036] Please combine Figure 1 to Figure 3 As shown, the present invention provides a monitorable prestressed component, including a prestressed body 1, a prestressed tendon 6 passing through the prestressed body 1, a long-gauge carbon fiber strain sensing unit 2, and a built-in microcircuit board 3 , component surface output port 4 , radio frequency electronic tag 5 . The long gauge carbon fiber strain sensing unit is formed by encapsulating a long gauge carbon fiber strain sensing element with a composite material sleeve. The long gauge carbon fiber strain sensing unit 2 includes at least one long gauge carbon fiber strain sensing element. The long gauge carbon fiber strain sensing element is arranged on the surface of the prestressing tendon 6 along the axial direction of the prestressing tendon; the long gauge carbon fiber strain sensing unit is connected through the built-in microcircuit board 3 of the component, and then passes through the output port 4 on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com