Mechanical fault monitoring method for photoelectric composite submarine cable

A photoelectric composite and mechanical failure technology, which is applied in the direction of testing the strength of materials by using one-time impact force, testing the strength of materials by applying stable tension/pressure, and measuring devices. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

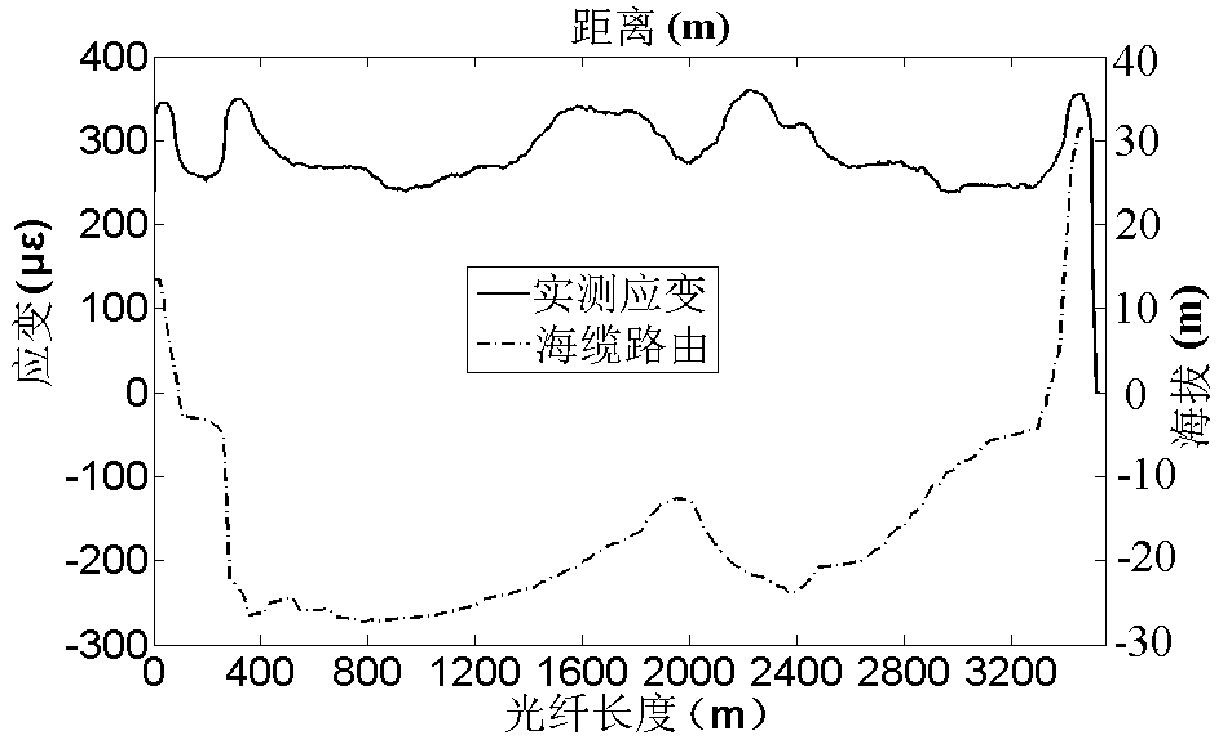

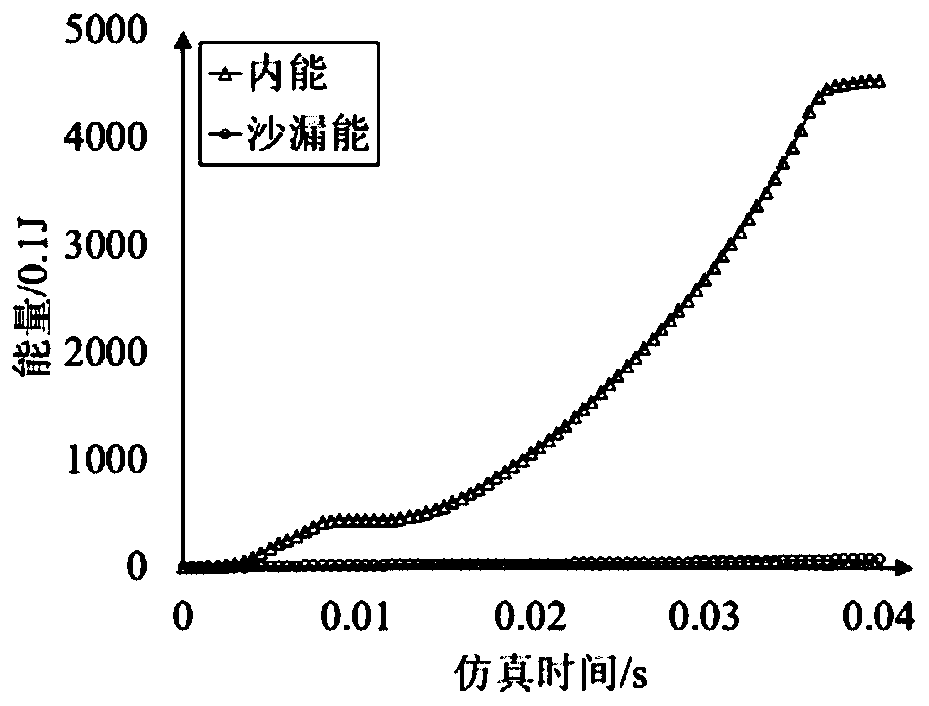

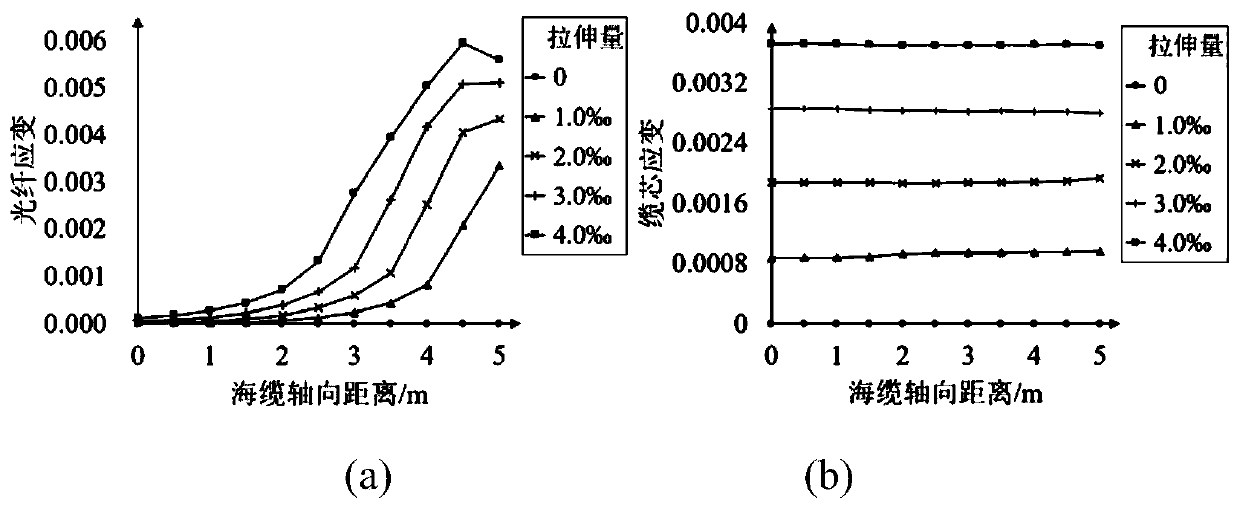

[0090] The present invention provides a mechanical fault monitoring method for a photoelectric composite submarine cable. In order to ensure the safe and stable operation of the submarine cable, we built and completed a 110kV YJQ41×300mm cable in 2012 2 Two islands A and B in a sea area in eastern China connected by a photoelectric composite submarine cable are used for power transmission, power system channel communication operation, and transmission of real-time operation information for grid scheduling automation; the invention uses 110kV YJQ41×300mm 2 Taking the type submarine cable as the research object, the finite element model of its structural dynamics was established based on the explicit dynamic analysis of ANSYS / LS-DYNA, and the three typical failure situations of submarine cable tension, torsion and anchor smashing were modeled and simulated, and the obtained The strain distribution along the composite optical fiber of the submarine cable under the above fault cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com