Simulation test system in variable load fiber strain karst collapse process

A karst collapse and process simulation technology, applied in soil material testing, material inspection products, etc., can solve problems such as the karst collapse process simulation test system that has not yet been found, and achieve the effect of convenient and simple installation and operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

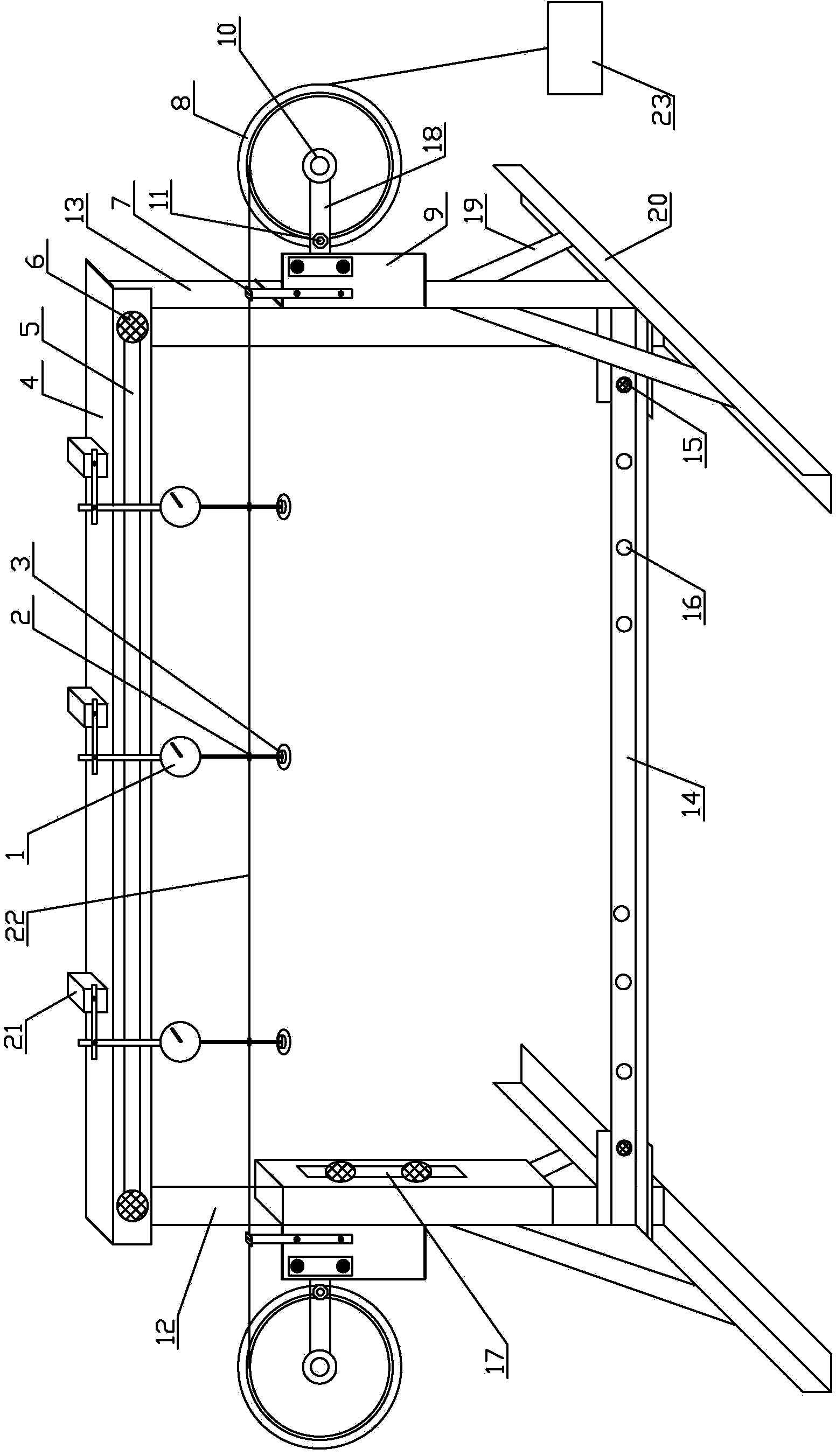

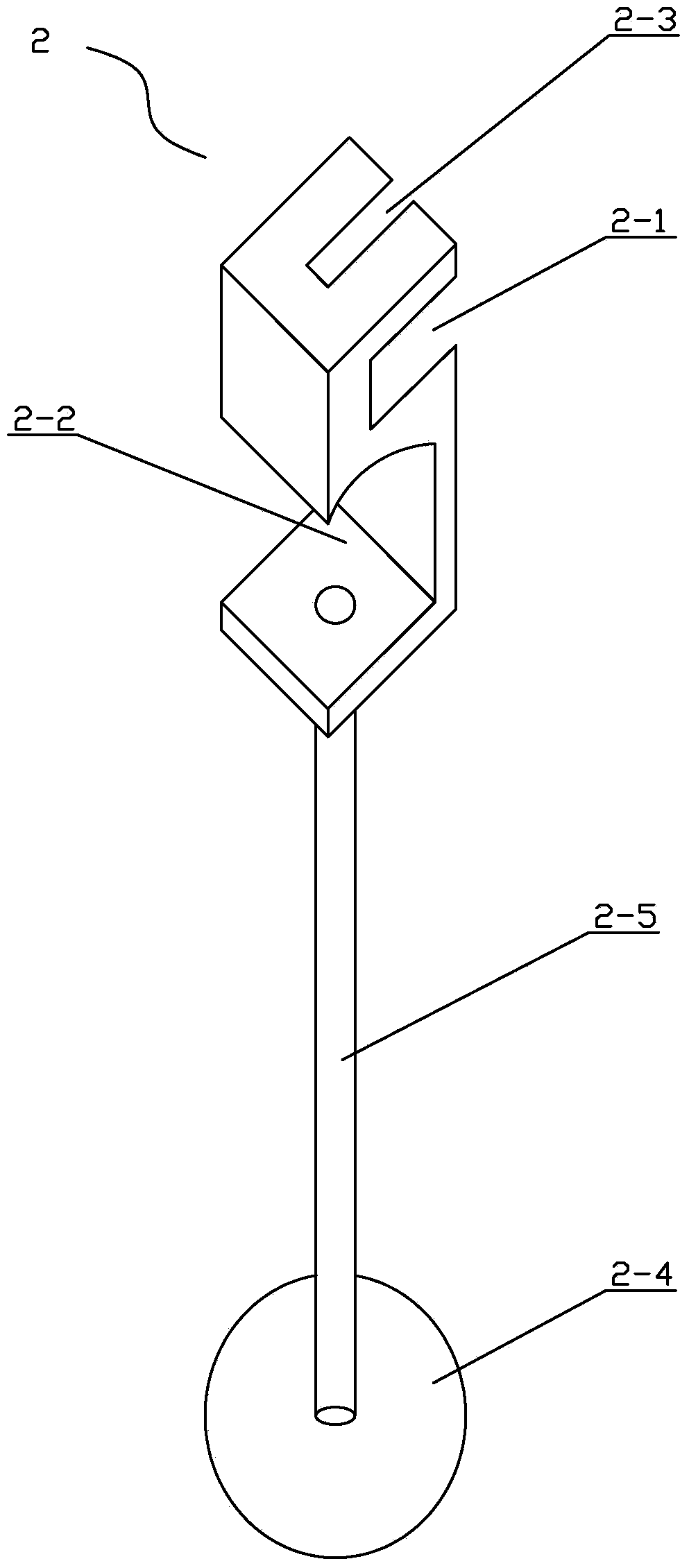

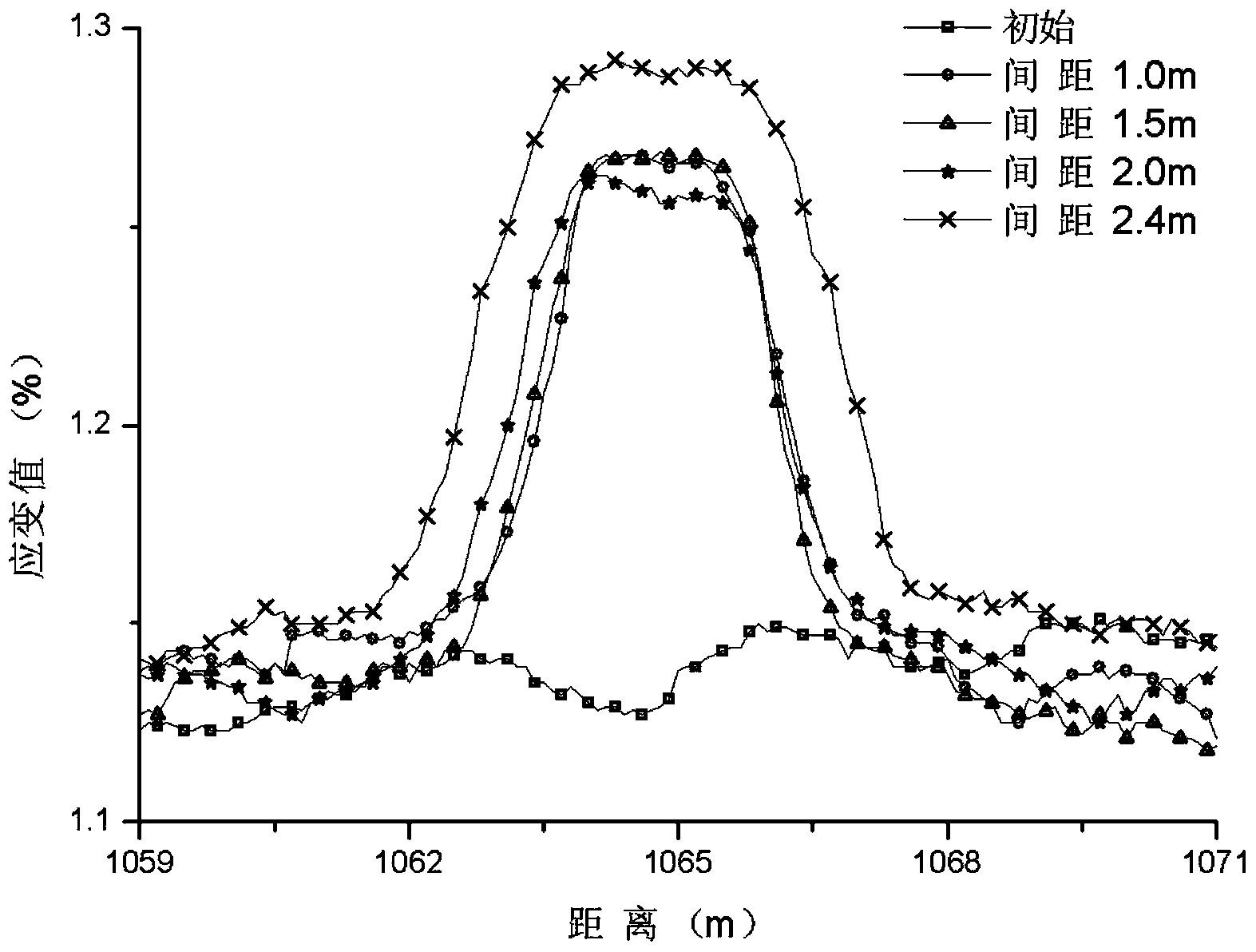

[0026] like figure 1 As shown, the variable-load optical fiber strain karst collapse process simulation test system of the present invention includes a strain gauge 23 (in this embodiment, specifically an optical fiber strain analyzer AQ8603) and a test device, and the test device includes a support mechanism, The base mechanism, the measuring mechanism and the fiber fixing mechanism, wherein:

[0027]Described supporting mechanism comprises the left bracket 12 that is arranged in vertical direction and the right bracket 13, the upper bracket 4 that is arranged in horizontal direction and the lower bracket 14; The support 13 is also provided with a moving groove 17 parallel to itself; the upper support 4 is provided with a span adjustment groove 5 parallel to itself, and the length of the span adjustment groove 5 is slightly less than the length of the upper support 4. In the lower support 14 There are several positioning holes 16 on the top; a hole is provided at the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com