Submarine photoelectric composite cable omni-directional monitoring and fault point accurate positioning method

A photoelectric composite cable and accurate positioning technology, applied in the field of measurement, can solve the problems of single detection means, the failure of the outer layer of the core wire fault can not be directly detected, and the inability to realize the submarine photoelectric composite cable, etc., to achieve the effect of ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

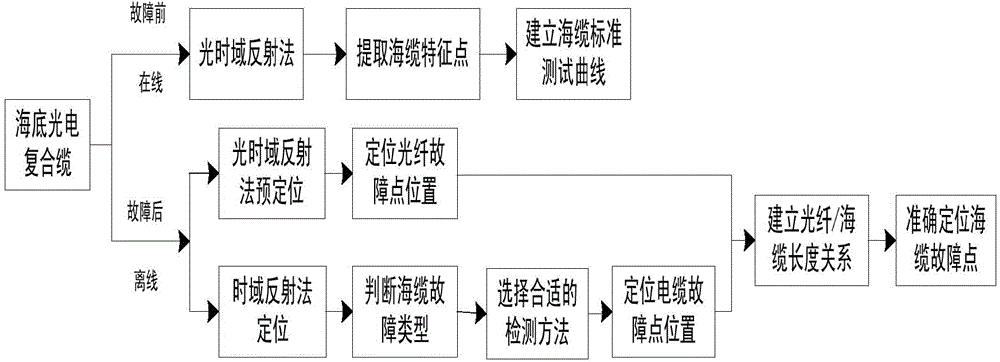

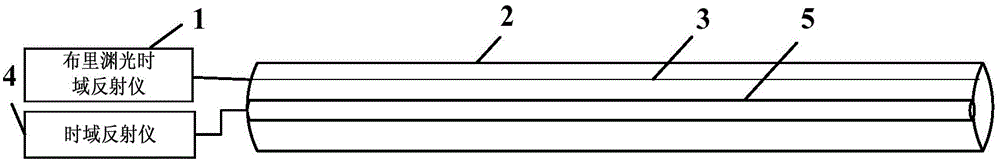

Method used

Image

Examples

Embodiment

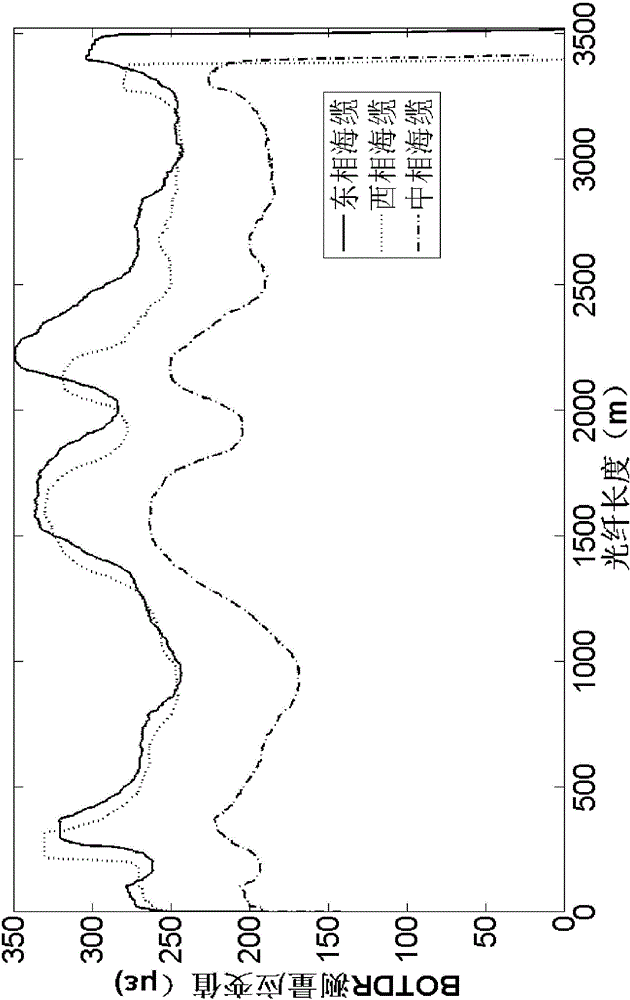

[0046] Embodiment: The determination process of the corresponding relationship between optical fiber and submarine photoelectric composite cable length:

[0047] The optical fiber is twisted in the submarine cable at a certain pitch, and the theoretical length of the optical fiber is calculated according to the diameter of the submarine cable and the twisting pitch.

[0048] Optical fiber length = photoelectric composite length of submarine cable * coefficient * excess length of optical fiber

[0049] Among them, coefficient={[(3.14*d) 2 +m 2 ] 1 / 2} / m; d is the diameter of the optical fiber in the submarine photoelectric composite cable, and m is the stranding pitch.

[0050] However, with the influence of coiled cable and excess length, the actual measured optical fiber length is greater than the theoretically calculated optical fiber length. Therefore, it should be combined with the specific position of each feature point obtained in the actual test, firstly correspond t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com