Multifunctional intelligent anchor pole and installation arrangement method thereof

A multi-functional, bolting technology, applied in the installation of bolts, mining equipment, measuring devices, etc., can solve the problems of stress and strain conditions, such as convergence deformation and stability of surrounding rock, no related patents and related literature, etc., and achieve novel and ingenious testing methods. , The principle is simple and reliable, and the test accuracy is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

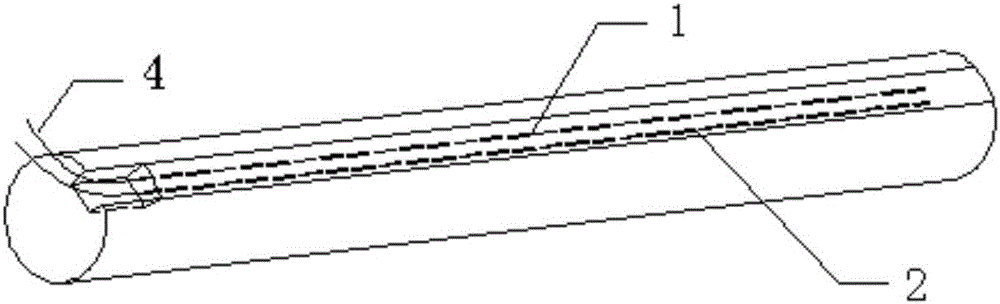

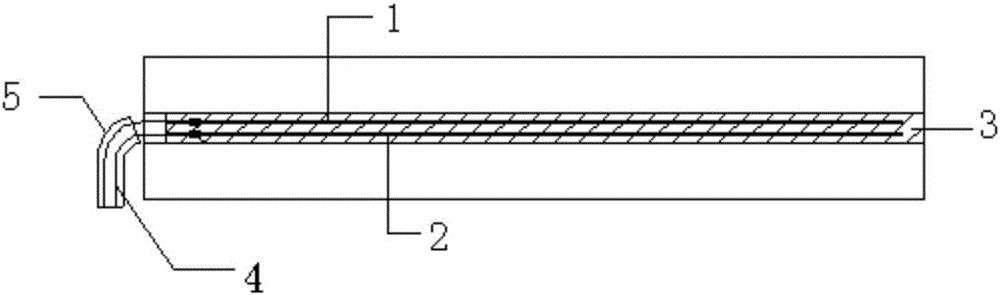

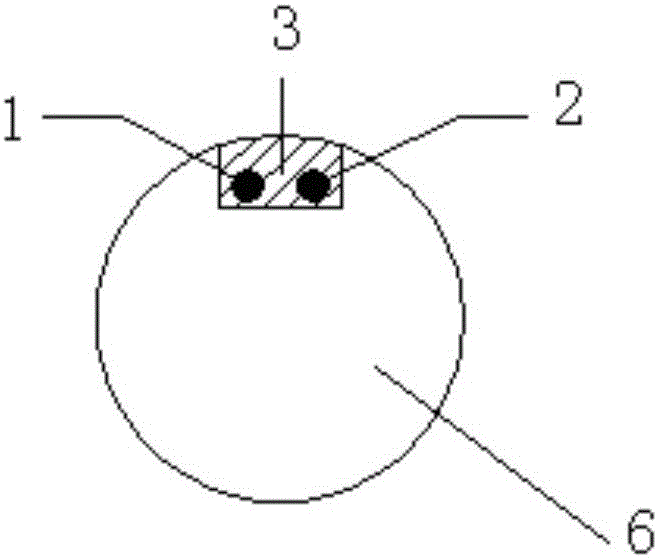

[0033] Such as Figure 1-5 As shown in the figure, a multi-functional intelligent anchor rod includes non-fused long-gauge-length multi-grating sensor 1, fiber-optic grating multi-point temperature compensation auxiliary sensor 2, epoxy resin or planting glue 3, armored optical cable 4 and soft plastic sleeve 5;

[0034] The non-welding long gauge length multi-grating sensor 1 and the fiber grating multi-point temperature compensation auxiliary sensor 2 are installed in the small groove opened in the longitudinal direction of the anchor rod 6, and are encapsulated by epoxy resin or embedding glue 3;

[0035] The non-fusion long gauge multi-grating sensor 1 includes a plurality of long gauge fiber grating sensing units connected in series in sequence, and the long gauge fiber grating sensing unit includes a sleeve, an optical fiber packaged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com