Mine belt conveyer state monitoring system

A condition monitoring system and belt conveyor technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problem that managers cannot understand the real-time operation status of equipment, equipment failures cannot be detected early, and the best time to deal with problems is missed and other issues to achieve the effect of ensuring authenticity, simple and reliable principle, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

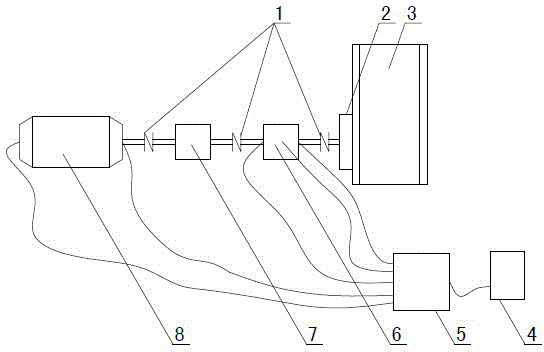

[0029] Figure 1~10 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~10 The present invention will be further described.

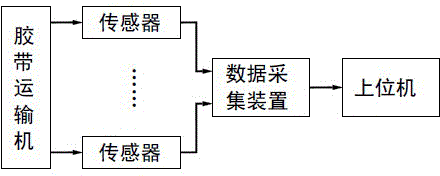

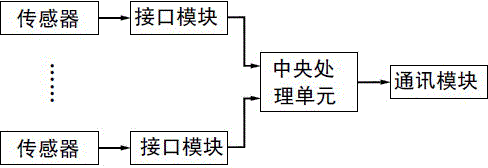

[0030] Such as figure 1 As shown, the mine belt conveyor condition monitoring system includes a mine belt conveyor, a plurality of sensors installed on the mine belt conveyor, a data acquisition device 5 and a host computer 4 .

[0031] The mine belt conveyor includes a motor 8 , a liquid viscous soft starter 7 , a speed reducer 6 and a driving drum 2 . Between the output shaft of the motor 8 and the input end of the liquid viscous soft starter 7, between the output end of the liquid viscous soft starter 7 and the input end of the reducer 6, and between the output end of the reducer 6 and the drive drum 2 respectively The connection is made via a coupling 1. After the motor 8, liquid viscous soft starter 7, and reducer 6 are connected in sequence, the drive drum 2 is driven to rotate through the output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com