Displacement extension clamping device for measuring axial tensile deformation of steel cable at high temperature and using method of displacement extension clamping device

A clamping device and axial stretching technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to process, large errors in the test data of the axial deformation of the sample, and prone to relative slippage. Good high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

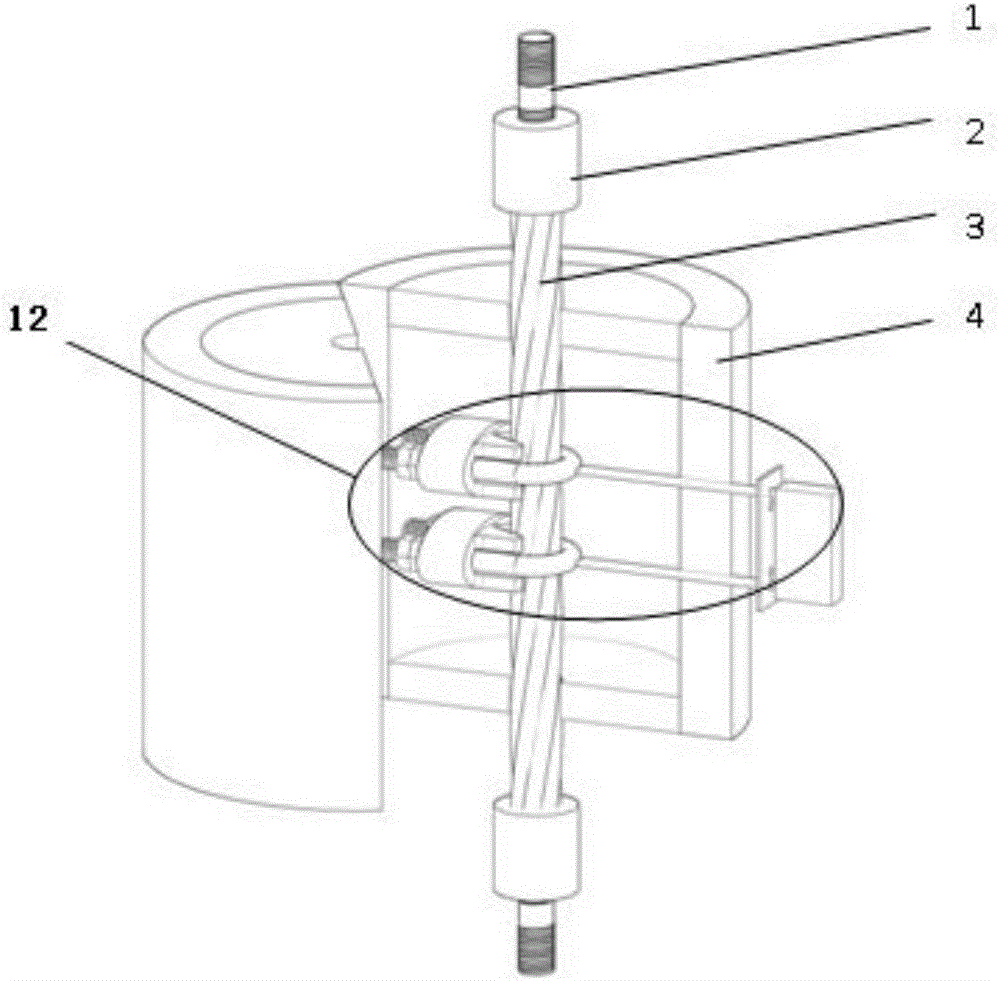

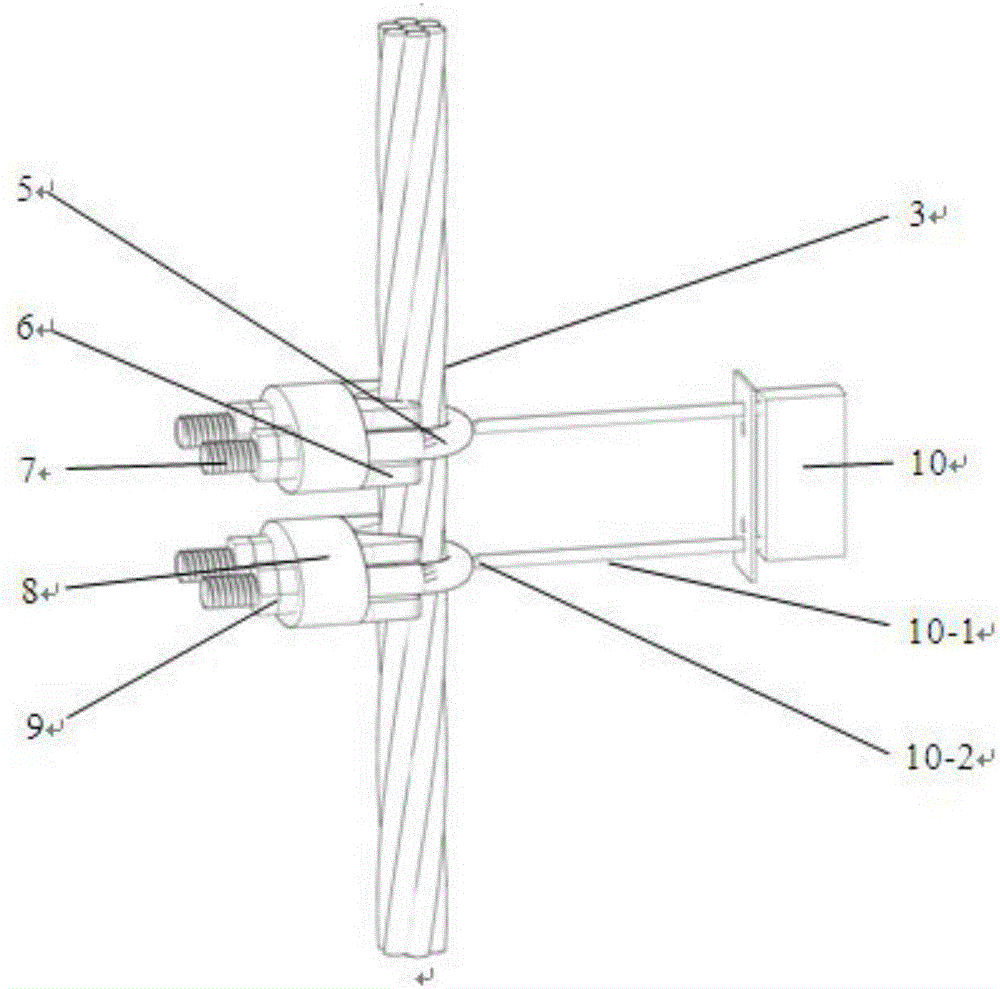

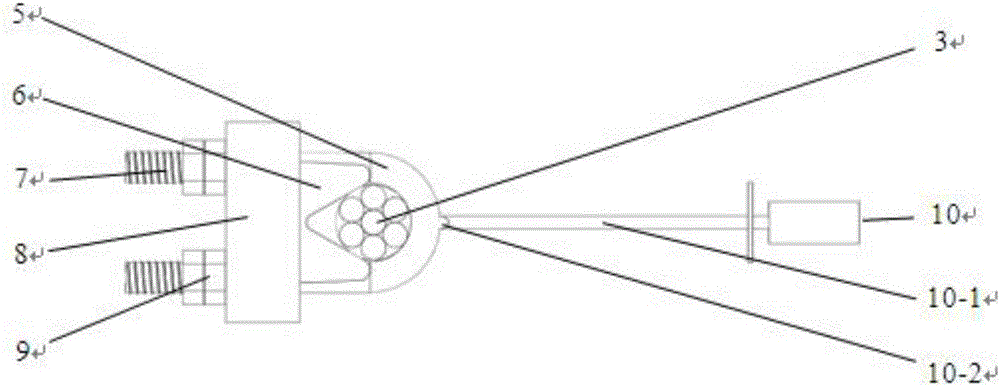

[0025] Such as Figure 1-4 As shown, a displacement extension clamping device 12 for measuring the axial tensile deformation of a steel cable at a high temperature includes an upper clamp, a lower clamp and a high temperature extensometer 10;

[0026] The upper and lower clamps both include U-shaped pipe clamps 5, V-shaped claws 6, bolts 7, bases 8, and high-temperature nuts 9; the U-shaped pipe clamps 5 are set on the sample 3, and the U-shaped pipe clamps 5 Both ends are respectively connected with two bolts 7, the base 8 is provided with a screw hole matching the above bolt 7, the bolt 7 passes through the screw hole in the base and is connected with the high temperature nut 9, and the base is also provided with a V-shaped claw 6 , the U-shaped pipe clamp 5 and the V-shaped claw 6 are relatively buckled to block the sample 3, and the high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com