High temperature resistant spring-type device for measuring metallic material deformation

A technology of metal materials and measuring devices, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of inability to measure the deformation of samples, insufficient measurement accuracy, and limited range, etc., to achieve Avoid eccentric stretching, easy installation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

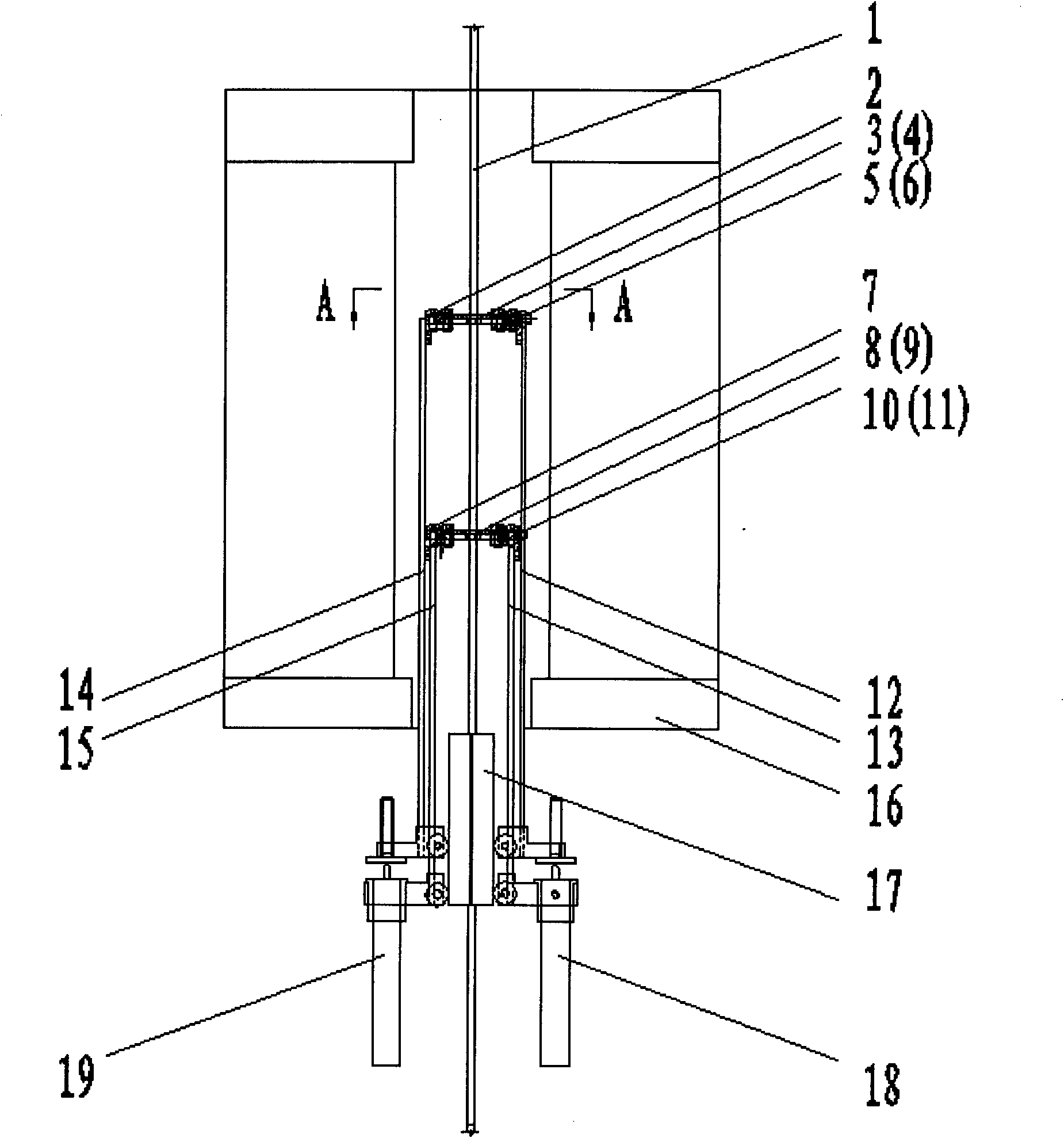

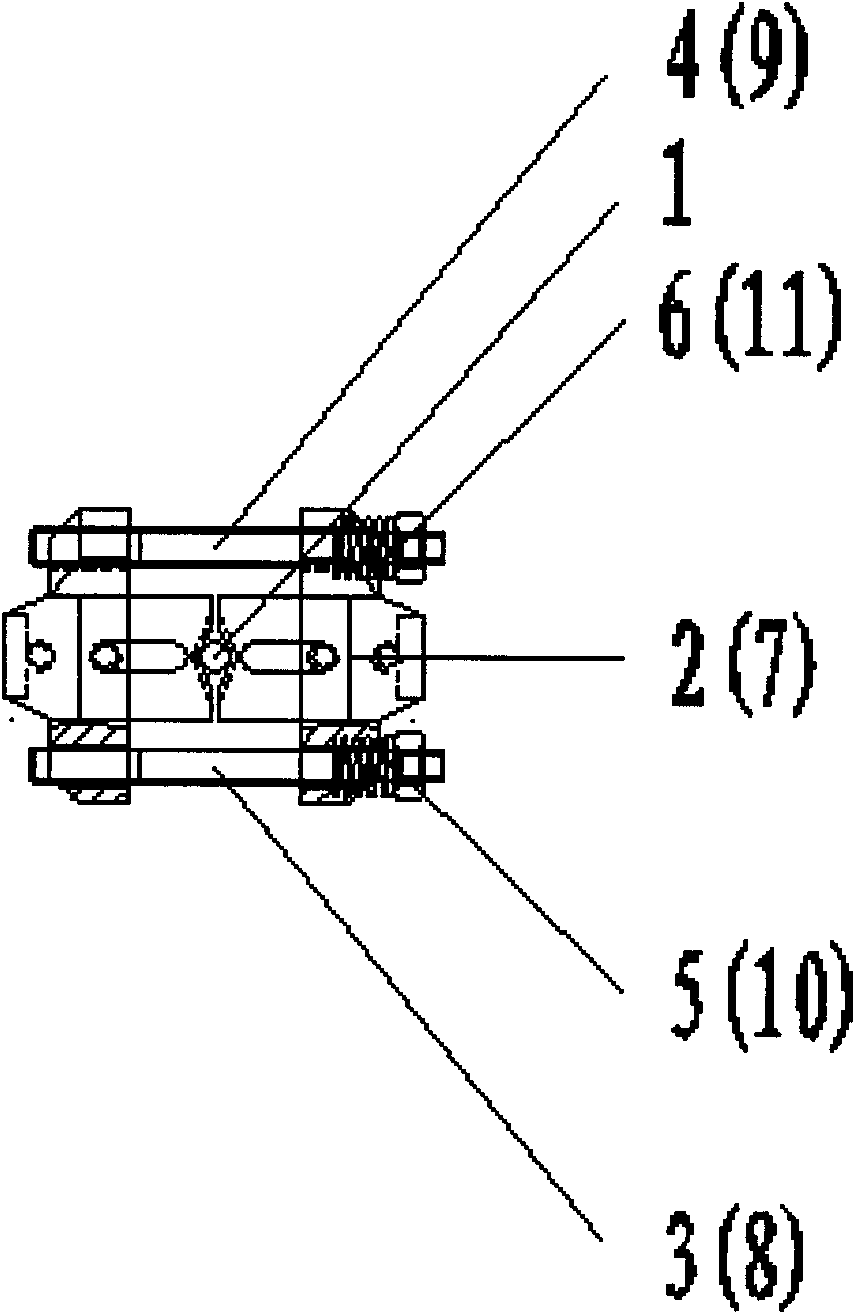

[0013] Such as Figure 1~2 As shown, a high-temperature-resistant spring-type metal material deformation measuring device includes a metal material sample 1, an upper clamping block 2, a piercing rod a3, a piercing rod b4, a high-temperature-resistant spring a5, a high-temperature-resistant spring b6, a lower clamping block 7, Through rod c8, through rod d9, high temperature resistant spring c10, high temperature resistant spring d11, extension rod a12, extension rod b13, extension rod c14, extension rod d15, high temperature furnace 16, guide block 17, differential transformer displacement sensor a18, Differential transformer displacement sensor b19.

[0014] First clamp the metal material sample 1 with the upper and lower chucks of the tensile testing machine, and then fix the two knife edges of the upper clamp block 2 to the upper gauge end of the sample according to the determined sample gauge distance, and the two knife edges pass through the two A parallel piercing rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com