A deformation measuring device for a boss-free metal material high-temperature tensile test

A metal material, tensile test technology, applied in the direction of measuring device, electromagnetic measuring device, electric/magnetic solid deformation measurement, etc., can solve the problems of expensive, limited range, difficult to apply, etc., to avoid eccentric stretching and low cost , Improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

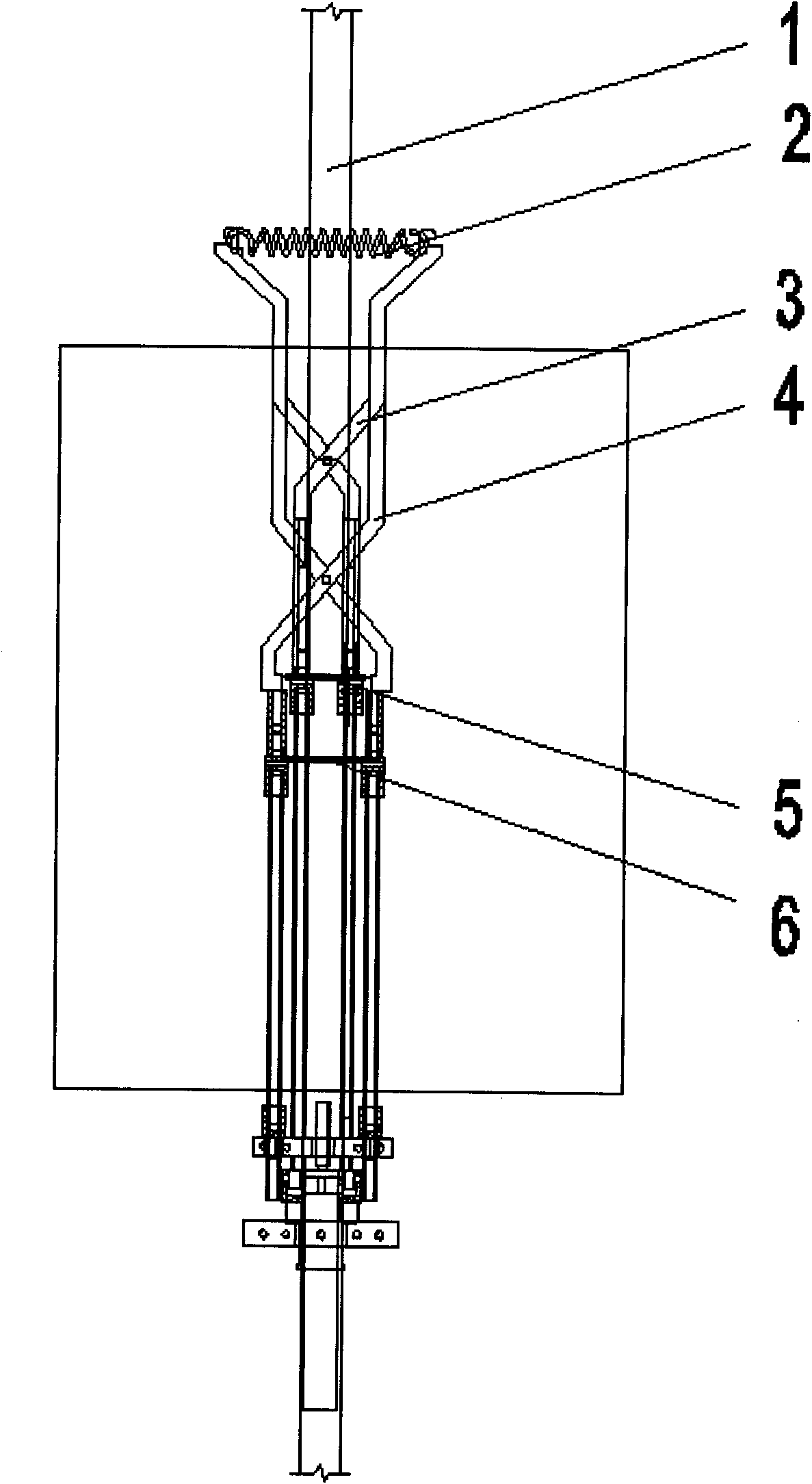

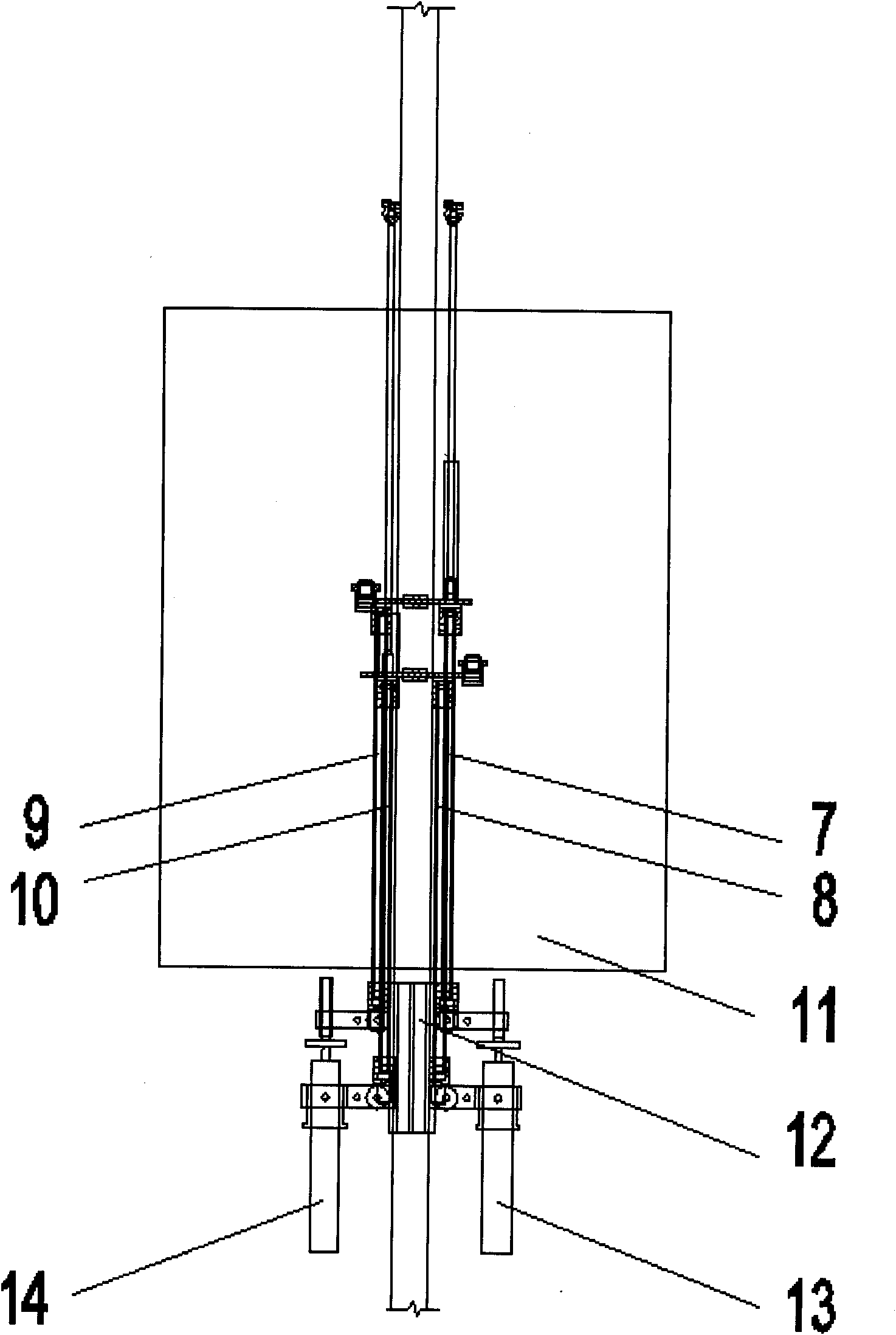

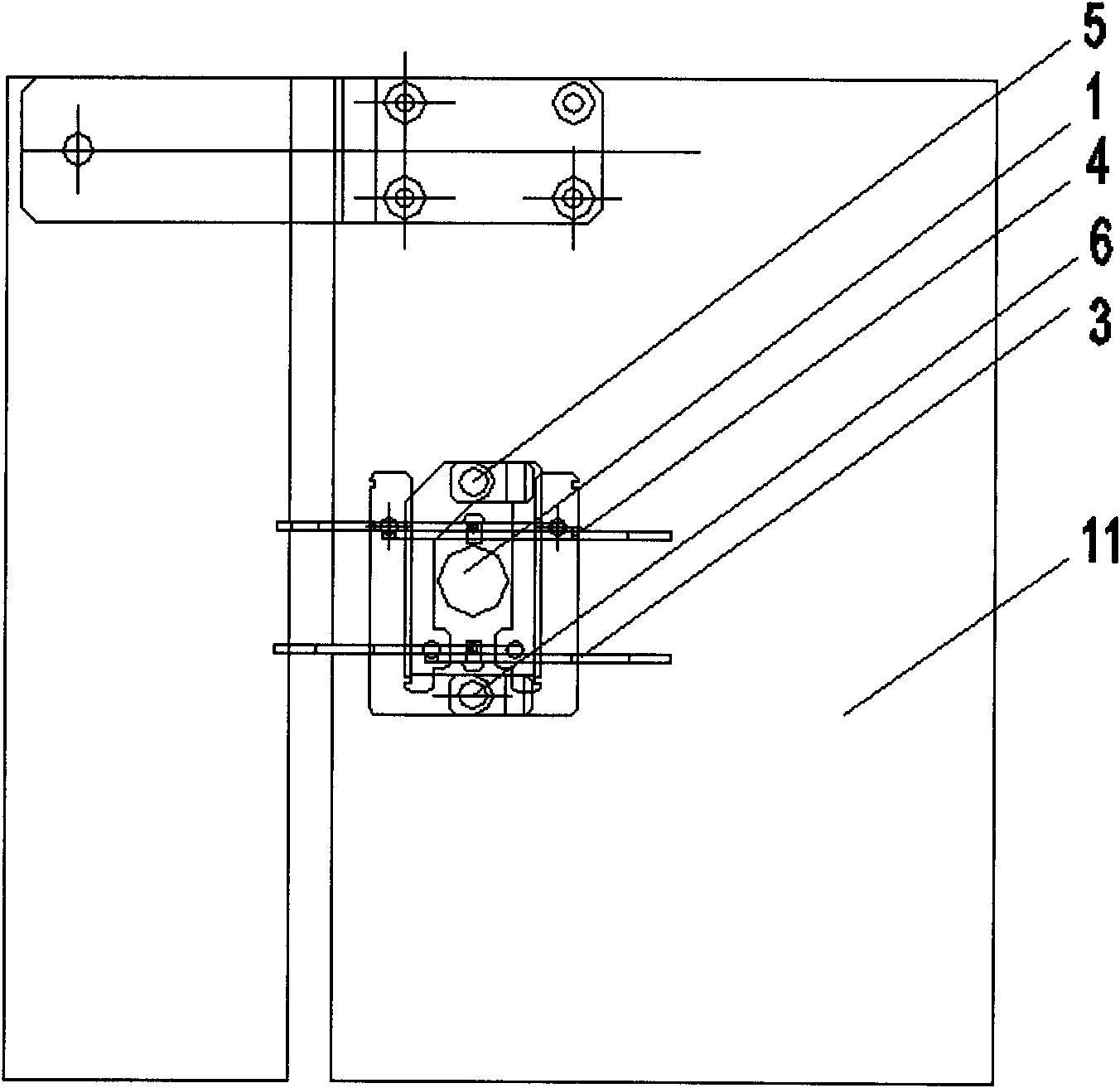

[0019] Such as Figure 1~3 As shown, a deformation measurement device for high temperature tensile test of metal materials without bosses, including spring 2, upper scissor device 3, lower scissor device 4, upper clamp 5, lower clamp 6, extension rod a7, extension rod b8 , Extension rod c9, extension rod d10, high temperature furnace 11, guide block 12, differential transformer displacement sensor a13, differential transformer displacement sensor b14.

[0020] When in use, first clamp the metal material sample 1 with the upper and lower clamps of the tensile testing machine, and then fix the two splints of the upper fixture 5 to the upper gauge end of the sample according to the determined sample gauge length. One end is fixedly connected together, and the other end is respectively connected to the upper scissor device 3. The tops of the two scissor-type hinged pull rods of the upper scissor device 3 stretch out from the top of the high-temperature furnace 11, and are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com