Horizontal concrete uniaxial tensile test device and use method thereof

A technology of uniaxial tension and testing equipment, which is applied in the direction of measuring equipment, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of reducing the accuracy of tensile test results, height restrictions, etc., and improve the use of range, eliminate initial stress, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

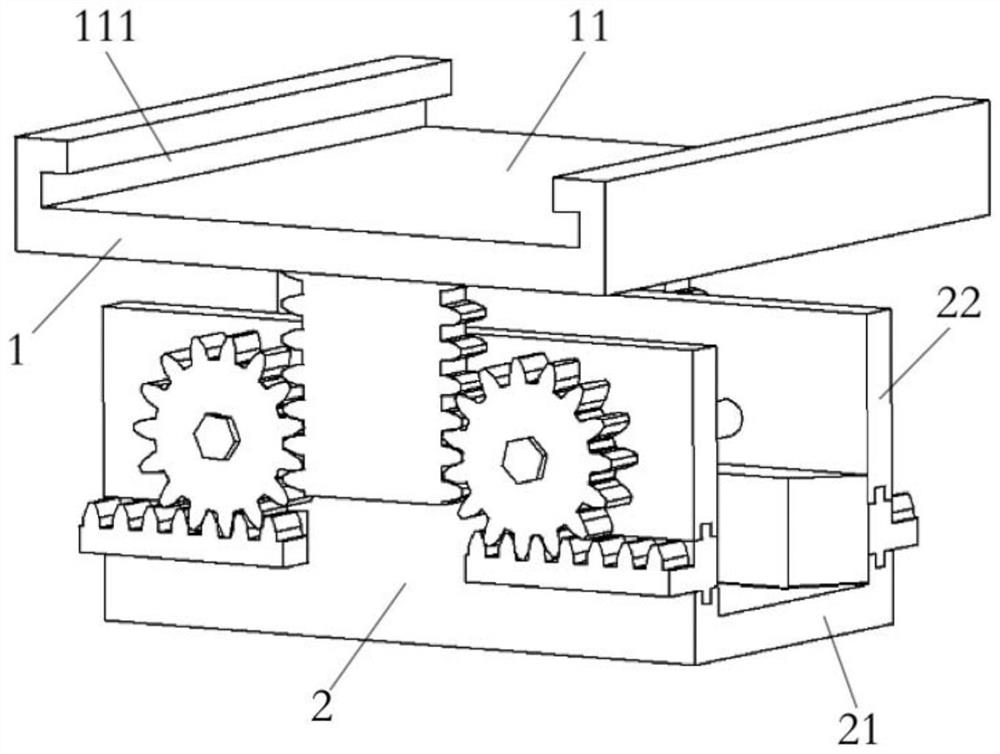

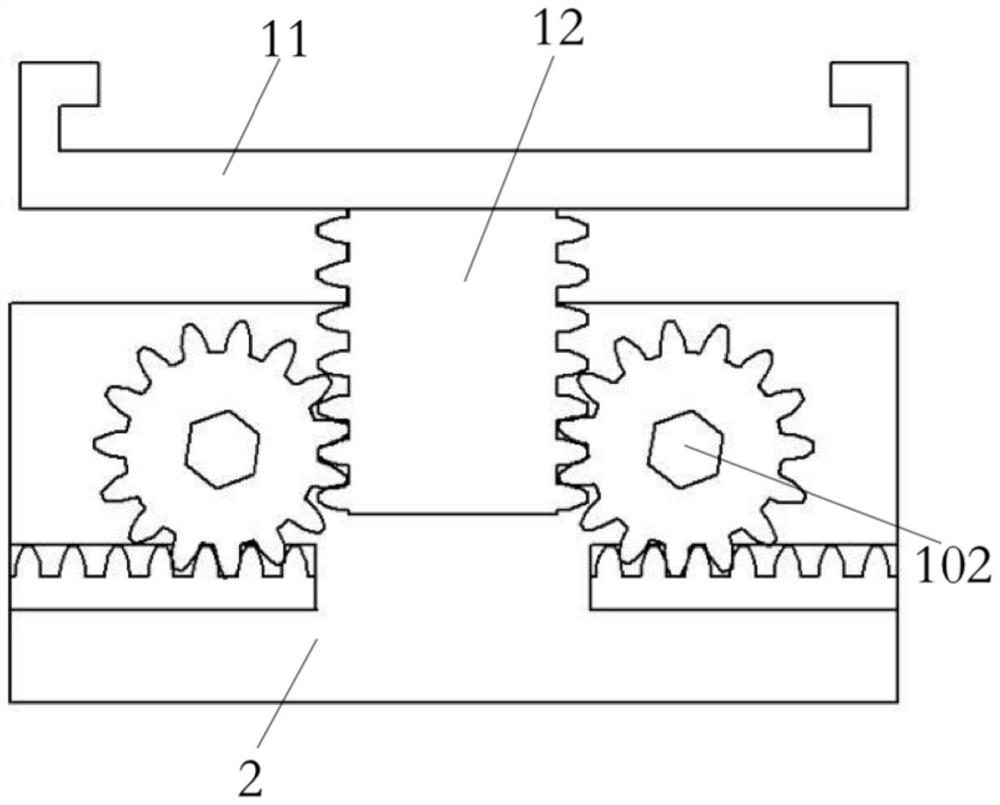

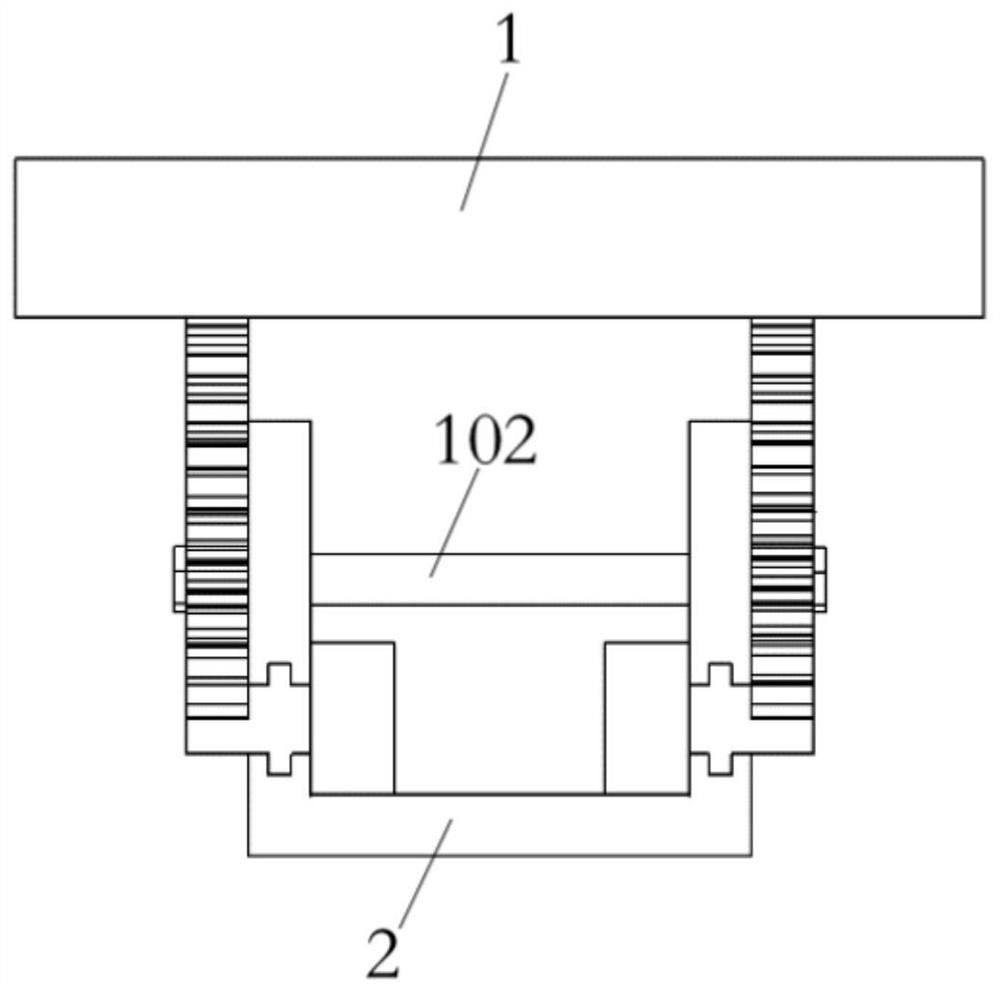

[0065] as attached Figure 1-15 As shown, this embodiment provides a horizontal concrete uniaxial tensile test device, which includes a pressing member 1, a base 2, a first rack clamping body 4, a second rack clamping body 5, and a third rack clamping body. The rack clamping body 6, the fourth rack clamping body 7, the first transmission gear 8, the second transmission gear 9, the third transmission gear 10, the fourth transmission gear 101 and the gear transmission shaft 102.

[0066] The lower pressure piece 1 is arranged above the base 2, the lower pressure piece 1 includes a pressure plate 11 and two vertical racks 12, the pressure plate 11 is horizontally arranged above the base 2, the upper end surface of the pressure plate 11 is in contact with the upper pressure plate of the testing machine Connection; the upper end surface of the pressure plate 11 is provided with a fixed card slot 111, the fixed card slot 111 is set horizontally, and the upper platen of the testing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com