Direct tension test testing device for high-freedom degree fragile material and a testing method based on device

A brittle material, test and test technology, applied in the direction of measuring devices, analyzing materials, strength characteristics, etc., can solve the problems of no deflection structure, poor space rotation ability of the stretching device, low adjustment sensitivity, etc., to achieve wide application range and economy considerable benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

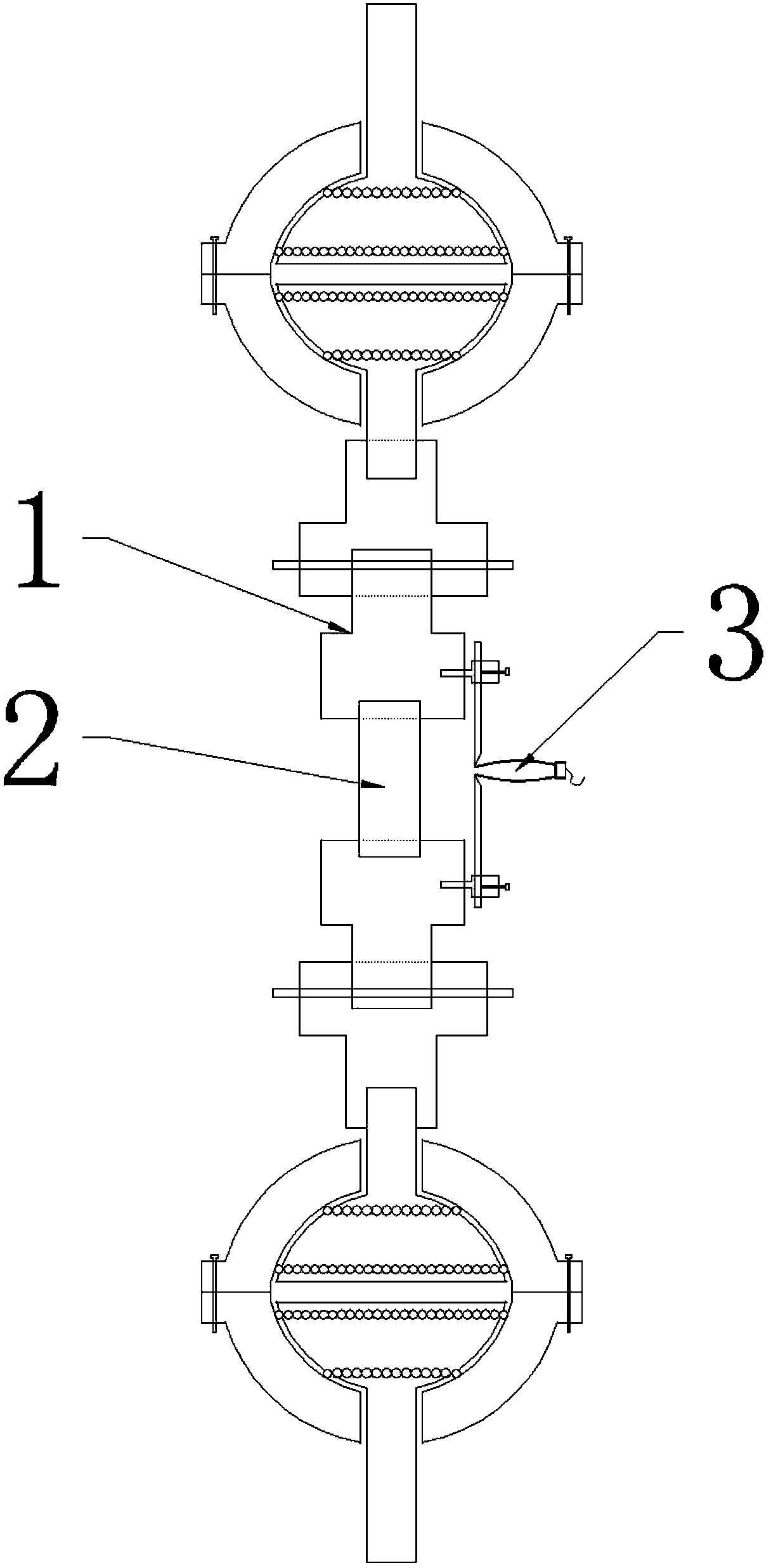

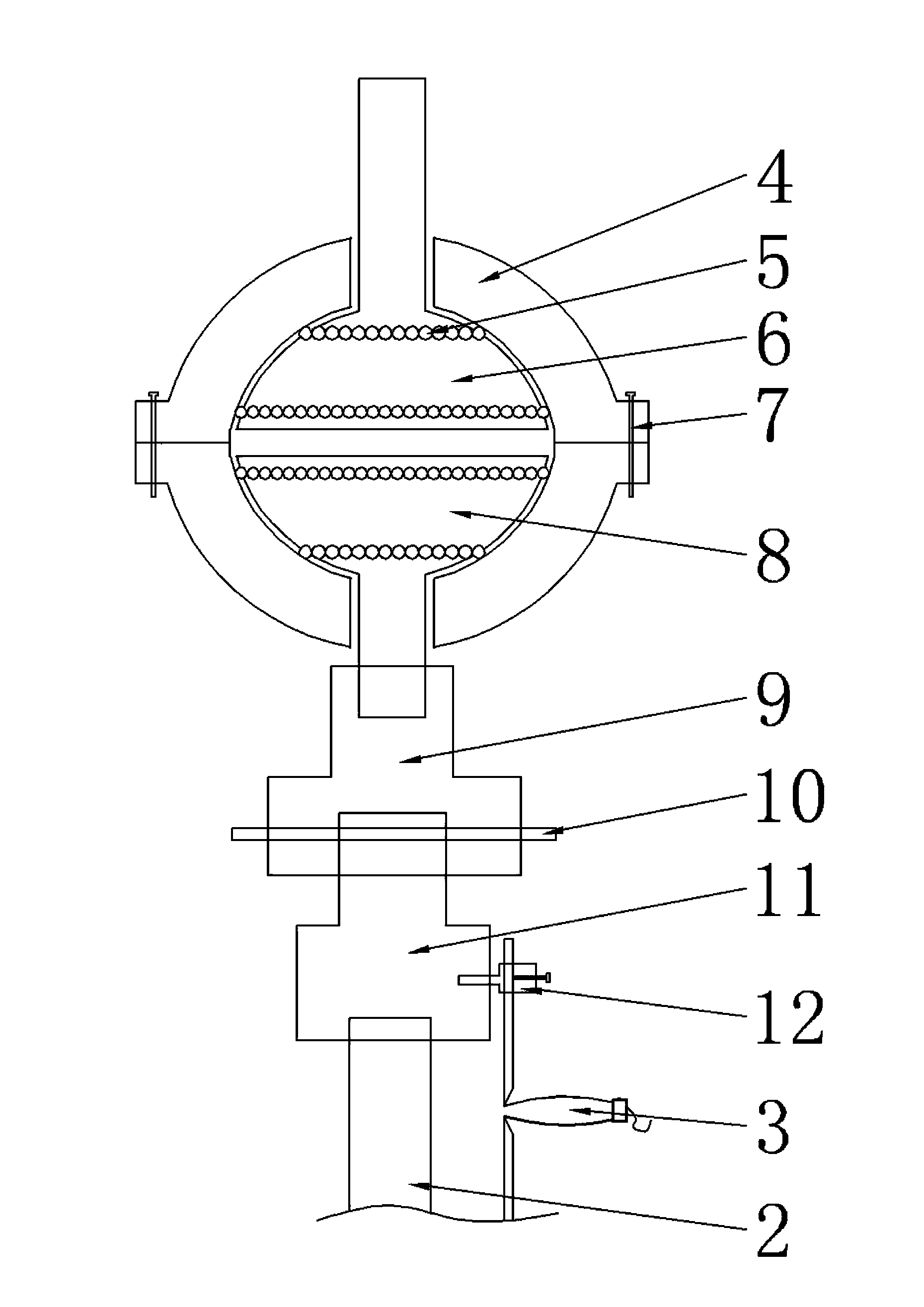

[0033] see figure 1 , figure 2 A schematic diagram of a preferred embodiment of a high-degree-of-freedom brittle material straight-pull test device. In this embodiment, the test device includes two groups of gyro centering adjustment devices 1 and precise deformation monitoring devices 12 with the same structure. The gyro centering adjustment device 1 and the precise deformation monitoring device 12 are symmetrically positioned along the center line of the COD extensometer 3 .

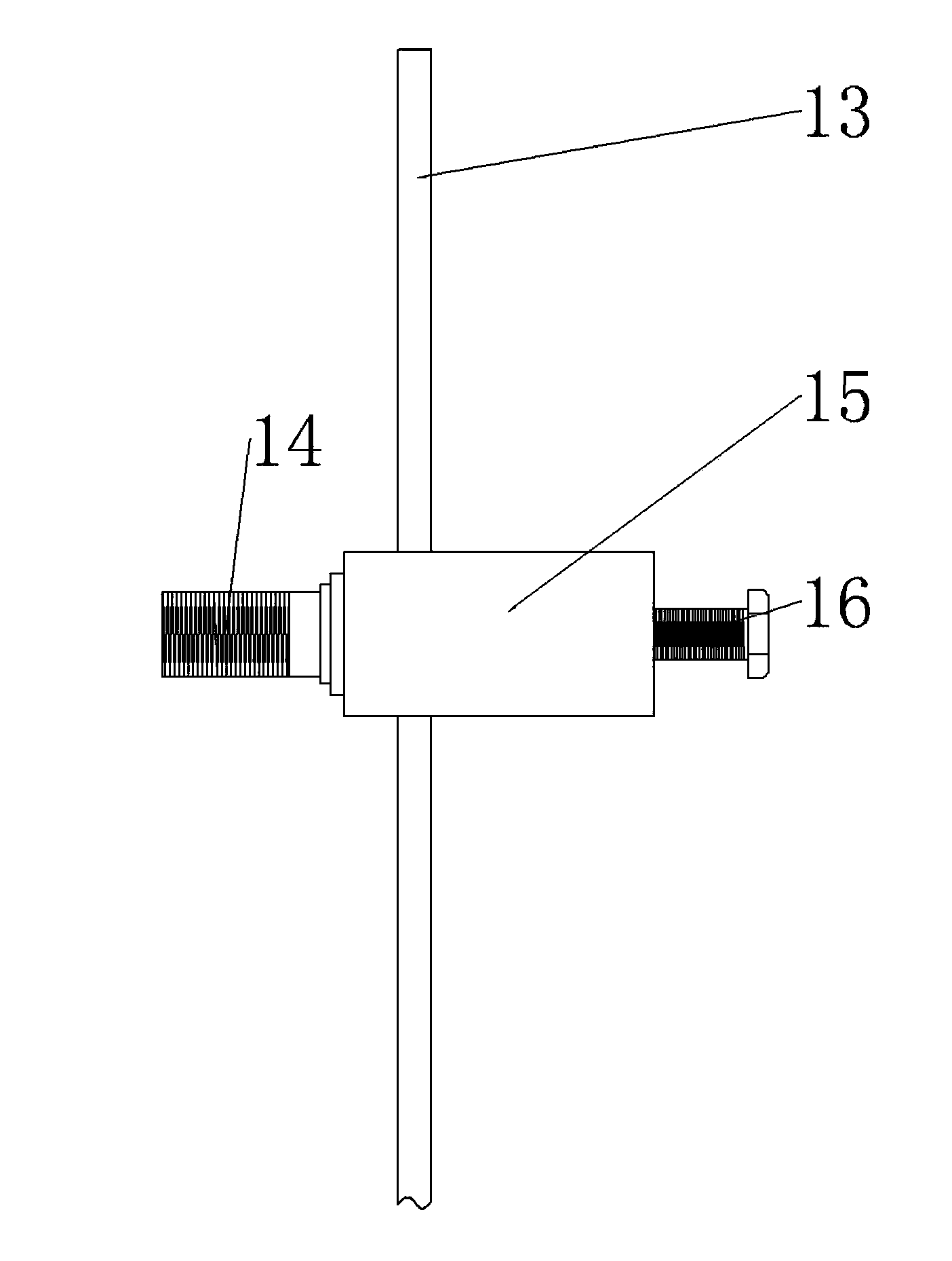

[0034] Each set of gyro centering adjustment devices 1 includes a spherical seat 4. The spherical seat 4 includes two hemispherical gyro cavities, the upper and the lower. There are spherical hinge tie rods 6 and spherical hinge connecting rods 8, the base structures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com