Bidirectional long-gauge-length fiber grating strain sensor

A technology of strain sensor and optical fiber grating, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of waste, strain gauges that cannot meet the measurement requirements, time-consuming and labor-intensive sensors, etc., and achieve the effect of sufficient protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

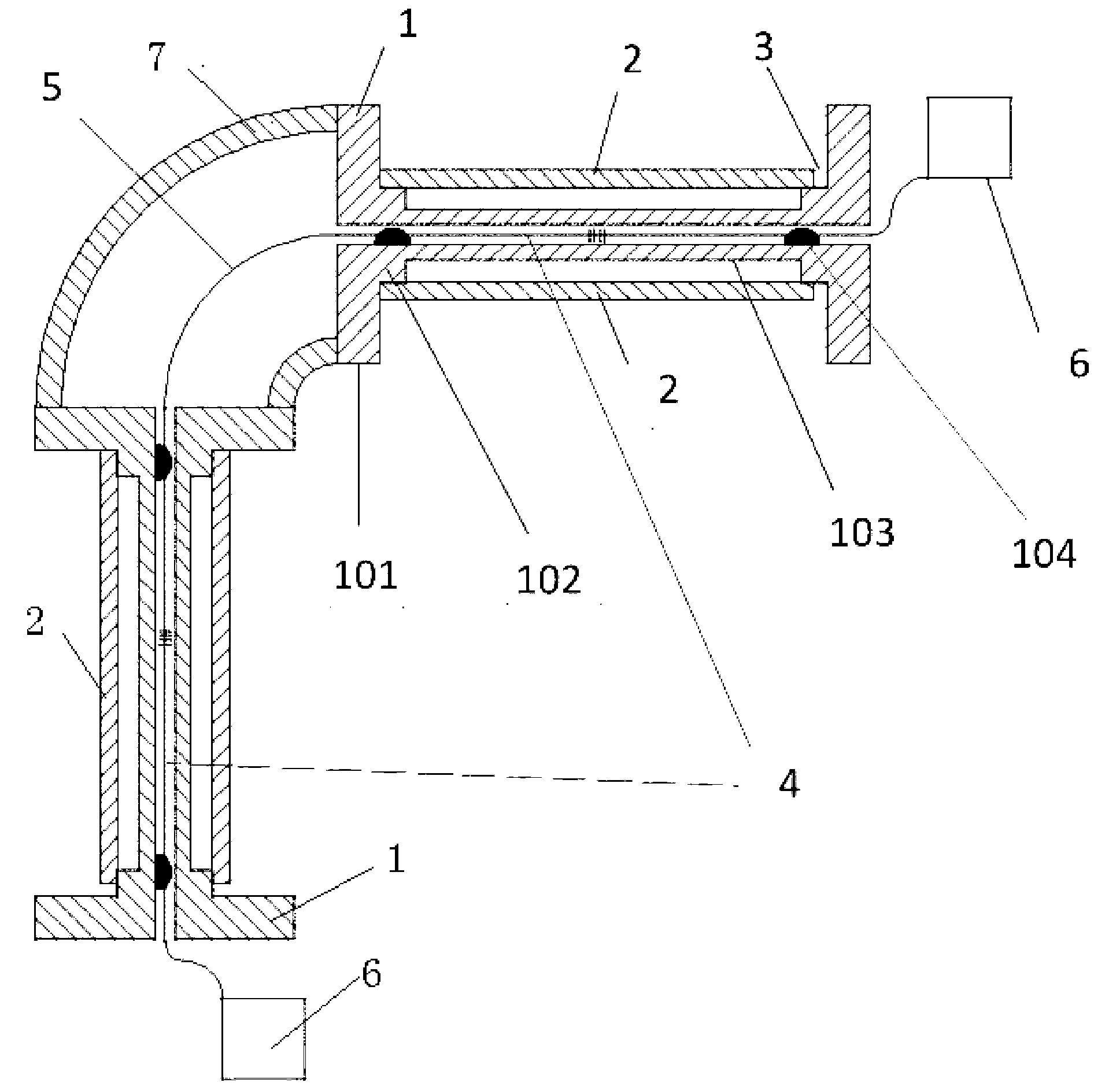

[0016] See attached figure 1 , a bidirectional long-gauge fiber grating strain sensor, which includes two mutually perpendicular measuring devices connected as a whole via an elbow 7 .

[0017] The measuring device includes a force bearing and deformation part, a fiber grating sensor 4 and a fiber grating regulator 6 connected with the fiber grating sensor 4 .

[0018] The stressed and deformed part comprises two stainless steel discs 101 for bearing pressure and a stainless steel tube 103 which is arranged between the two stainless steel discs 101 and is integral with it, and the diameter of the stainless steel tube 103 is smaller than that of the stainless steel disc 101. diameter; the transition between the stainless steel disc 101 and the stainless steel pipe 103 is through the provided stainless steel cylinder 102, and the stain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com